دع Istar يساعدك على البدء في مشروعك من خلال خبرتنا ودرايتنا!

قم بتحميل ملفات التصميم ومتطلبات الإنتاج الخاصة بك وسنعاود الاتصال بك في غضون 30 دقيقة!

People often ask me, “What’s the real difference in the cast iron vs steel talk?” The answer is very important. Picking the wrong one for your job can be expensive and waste time. That’s why I want to share what I’ve learned from my own work. This article will explain iron and steel, from start to finish. We will look at how carbon changes everything and see the good and bad things about each metal. By the end, you’ll know exactly which one, cast iron or carbon steel, is right for your job.

While they are similar, the difference between cast iron and steel is very big. The biggest difference is how much carbon is in the metal. It’s like baking. A little flour changes the cake a lot. It’s the same with carbon in iron and steel.

Cast iron has more than 2% carbon. This extra carbon makes cast iron very strong when you press on it. But, it also makes it break easily, so it can snap without bending. Steel, however, has less than 2% carbon. This lower amount of carbon means steel can bend. You can bend it and it will not break as easily. This is an important thing to know in the cast iron vs steel topic. So, when you look at cast iron and steel, know that the carbon content is the main reason they are so different. Making both starts with iron ore, but the amount of carbon put in makes the final metal different.

The amount of carbon in the metal is very important for both cast iron and steel. I’ve seen how a small change in carbon content can change how a metal acts. In cast iron, the high carbon level creates graphite. This gives cast iron some of its special features. It helps soak up shaking, which is great for the base of a big machine.

In steel, the lower carbon amount lets the iron make a different kind of structure. This makes steel stronger when you pull on it and makes it tougher. There are many kinds of steel, like carbon steel and stainless steel. Mild steel is a kind of carbon steel with very little carbon, making it simple to use. The carbon in alloy steel is combined with other things like chromium or manganese to make it special. The job of carbon is the main thing to know about how any iron or steel product will work.

This is a question I get a lot from people making new parts for machines. It depends on the part’s job. For parts that need a fancy shape, cast iron is usually the best choice. The casting process for iron is very good at filling tiny spaces in a mold. This means you can make parts with lots of detail with less extra work after the casting. This can save money and time.

But, if the part needs to take a lot of pulling or sudden hits, cast steel is usually the better pick. Cast steel is stronger when you pull it than cast iron. This means you can pull it harder and it won’t break. Steel casting can make parts with great strength and ductility. So, for things like gears or valves that get a lot of hard use, I would choose cast steel. It all comes down to what is needed for the machine and its parts.

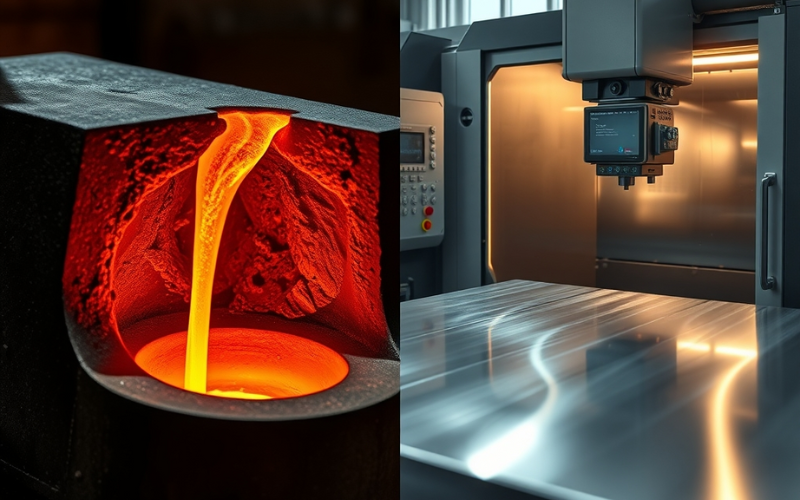

From my time at the foundry, I’ve seen that casting with iron is usually easier than with steel. There are a few main reasons for this. First, cast iron melts at a lower temperature than steel. This means you don’t need as much heat to melt the iron. A lower melting temperature makes the whole metal casting job cheaper and simpler to handle.

Another big reason is that molten iron flows better. This means it gets into all the small parts of a mold more easily. Because of this, it’s easier to cast than steel, especially for fancy shapes. Also, cast iron doesn’t shrink as much as steel when it gets cool. This is a big deal in a foundry because it means the part will likely be the right size. These things make cast iron a very common choice for many kinds of casting.

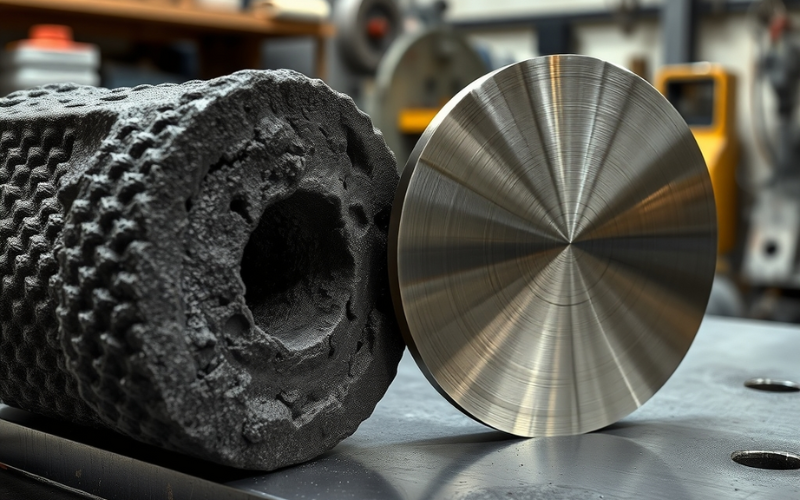

After a part is made in a mold, it usually needs more cutting. This means cutting it to the perfect final shape. In my shop, we do a lot of machining cast iron. I’ve always found that cast iron is often a simple material to use on a CNC machine. The graphite in the cast iron is like oil for the cutting tool. This helps cut smoothly and makes tools last longer. Gray cast iron is famous for being easy to cut.

Carbon steel, especially mild steel, is also simple to cut. But some of the stronger alloy steel kinds can be harder to use. They can wear out cutting tools faster and may need to be cut more slowly on the CNC machine. The machinability of a metal is very important to think about because it changes the price and time needed to make a final part. It’s always a good idea to think about how you will machine the part before you pick the material. It’s often easier to machine than cast to a final shape.

Welding is a normal job in any metal shop, but welding cast iron is very different from welding steel. From what I’ve seen, trying to weld cast iron can be hard. The high carbon content that makes cast iron so good also makes it hard to weld. When you heat it to weld it, it can break easily when it cools. You have to be very careful and often need special tools and ways to do it right.

But steel, especially mild steel, is very easy to weld. The lower carbon content means it’s easier to work with. You can get a good, strong weld without extra work. This makes it great for welding and is a big reason why steel is used a lot for building things. When talking about cast iron vs cast steel, if you need to weld a lot, steel is usually the simpler choice.

People often think hardness is a plus, and sometimes it is. For cast iron, its natural hardness is a big help sometimes. I’ve seen cast iron parts last a long time where a softer metal would wear out fast. Think about the base of a big machine. It needs to be stiff and not wear down. This is where the hardness of cast iron is great.

This hardness also means cast iron is very strong when you press on it (compressive strength). This means it can hold a lot of weight on top of it without breaking. That’s why you see it used for parts like engine blocks. While it might not have the strength than steel when pulled or bent, it is very good at handling pressure and wear. The hardness of cast iron is an important thing about it.

Rust is a problem for both iron and steel. I’ve seen many parts destroyed by it. In the fight against corrosion, it’s not always easy to say which is better. Normal cast iron and carbon steel will rust if you don’t cover them. You usually have to paint them or put on another type of coat to protect them from water.

But, some kinds of iron and steel are much better at stopping rust. For example, stainless steel has chromium in it, which makes a safe layer on the outside. This helps it fight rust very well. There are also kinds of ductile iron that are better at stopping corrosion than normal gray iron. Usually, cast iron resists wear and some kinds of corrosion very well. When picking between steel and cast iron, you should think about where the part will be and how much rust it might get.

| الميزة | حديد مصبوب | الفولاذ الكربوني |

|---|---|---|

| محتوى الكربون | More than 2% | Less than 2% |

| قوة الشد | أقل | أعلى |

| Compressive Strength | أعلى | أقل |

| الصب | Easier to cast | Harder to cast |

| قابلية اللحام | صعب | سهولة |

| قابلية التصنيع | رائع | جيد |

| مقاومة التآكل | OK (can be better) | Bad (without a coat) |

| التكلفة | Cast iron is cheaper | التكاليف أكثر |

There are different kinds of cast iron. I’ve worked with a few, and each is used for different things. The shape of the carbon inside the iron is very important. Here are some of the main kinds you will see:

Knowing these different kinds of cast iron helps you pick the right one from many different materials for what you need.

So, after all this talk about iron and steel, what’s the main point? Let’s list the good and bad things about each. I learned this from doing the work over many years. Picking between cast iron vs steel is a very important choice.

For cast iron, the best things are its low price and how easy it is to make into fancy shapes. Cast iron is cheaper than cast steel. Its low melting temperature and how well it flows make the casting job fast and simple. It’s also great at stopping shaking and is very strong when pressed on. The biggest problem is that it breaks easily. It snaps instead of bending, and it’s hard to weld.

Steel, however, is the best for being tough and strong when pulled. You can bend it and hit it, and it probably will not break. Steel products are famous for lasting a long time. The fact that steel is easy to weld is also a big plus. The biggest problems are that it costs more to make and making things from steel casting is harder. So when you choose, think hard about what your job needs.