دع Istar يساعدك على البدء في مشروعك من خلال خبرتنا ودرايتنا!

قم بتحميل ملفات التصميم ومتطلبات الإنتاج الخاصة بك وسنعاود الاتصال بك في غضون 30 دقيقة!

Polyamide is a man-made polymer that is used in a lot of products we see all the time. You might know it by its more common name, nylon. It is in our clothes and even in the parts of our cars. In this article, I will tell you what I know about polyamide. I will look at its special features, the different kinds of it, and all the ways it is used. It does not matter if you are an engineer, a designer, or just someone who wants to know more about the materials around us. I think you will find this information helpful and fun to read.

Let’s start with the simple things first. A polyamide is a type of polymer. This means it is a very big molecule. It is made of many smaller parts that repeat, called monomers. A polyamide is special because it has something called amide bonds. These bonds connect the smaller parts together. You can picture it as a long chain. The amide bonds are the links that hold the chain together. This structure at a tiny level is what makes polyamide so amazingly strong and tough.

You can find polyamides in nature. For example, proteins like wool and silk are natural polyamides. But the polyamides I am talking about are the man-made ones. These man-made polyamides are very important materials. This is because they work very well and don’t cost too much. The most famous example is nylon. The DuPont company first made nylon in the late 1930s. It was a replacement for silk stockings that was much stronger. This material, which can be used in many ways, is a type of plastic. It can be made into thin threads for fabric. It can also be shaped into solid pieces for many different uses.

Yes, there are a lot of different kinds of polyamide. Each kind has its own special features. They are usually put into three main groups: aliphatic, semi-aromatic, and aromatic polyamides. The kinds you will see most often are called by numbers, like nylon 6 and nylon 6,6. These numbers tell you about the small parts that are used to make the polymer.

Here is a quick look at some common kinds of polyamide:

| Kind of Polyamide | What It’s Like | مكان استخدامه |

|---|---|---|

| نايلون 6 | Tough, does not wear out easily, and holds up well against chemicals. | Car parts, fabrics, machine parts. |

| Nylon 6,6 | Melts at a higher heat and is stronger than Nylon 6. | Strong plastics, parts for electronics, strong fibers. |

| Nylon 11 and 12 | Great against chemicals, bends easily, and does not soak up much water. | Gas lines for cars, air tubes, hoses that bend. |

| Aramids (Aromatic Polyamides) | Super strong and can handle a lot of heat. | Vests that stop bullets, parts for airplanes, safety clothes. |

Having these different kinds of polyamide is a big help for the people who make and design things. It means they can pick the exact kind of this polymer that has the right features for the job they need to do.

Nylon is a really great material. Its special features are why so many people have used it for a very long time. The word “nylon” is really a name for a whole group of polyamides. When it was first made, it was advertised as being “stronger than steel.” It was also said that it would never get a run in stockings. While the part about the stockings was not completely true, the strength of nylon is very real.

One of the main things that makes nylon so special is that it is both strong and stretchy. It’s a very strong and tough material that does not wear out easily. At the same time, it is very stretchy. This means you can stretch it, and it goes back to its first shape. Being both strong and stretchy makes it great for things like stockings, workout clothes, and other fabrics that need to be strong but also able to bend. Nylon is also very light. It holds up well against chemicals and oils. This means it can be used for even more things.

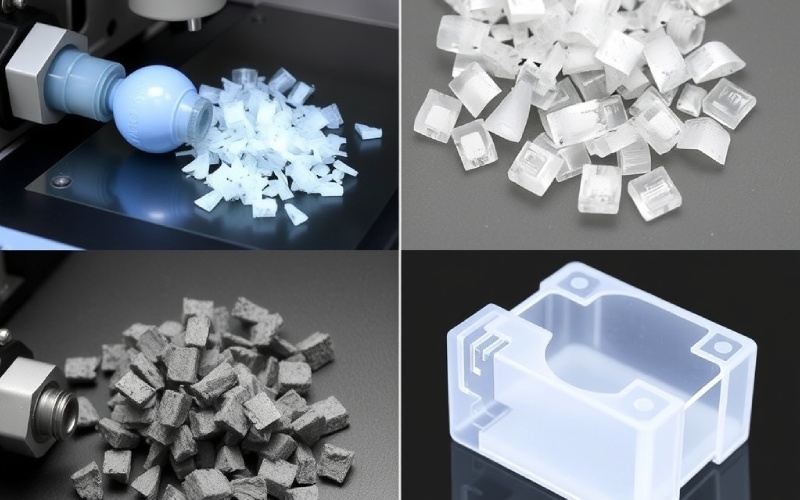

Making polyamide, and especially nylon, is an interesting process with chemicals. The main idea is to make long polymer chains from smaller monomer parts. These monomers usually come from crude oil. This makes nylon a product that starts with petroleum. The process used to make these polymers is called polymerization.

There are a few main ways to make nylon. A common way is to mix two different kinds of monomers: a diamine and a diacid. For example, the most popular kind of nylon is called nylon 6,6. It is made by mixing hexamethylenediamine and adipic acid. These two chemicals are mixed to make a salt. Then, the salt is heated up to make the long polymer chains of nylon. Another way is used to make nylon 6. It starts with just one monomer called caprolactam. After the polyamide is made, it can be pushed through a special tool with tiny holes to make fibers for fabric. It can also be put into a mold to make different shapes.

Polyamide fabric, which is often just called nylon, has features that make it very useful for making clothes and other textiles. One of its best-known features is that it is very strong and long-lasting. This is why it is used for everything from ropes and parachutes to carpets and furniture coverings. It does not get damaged easily from rubbing, so it can be used a lot without looking old.

Another key feature of polyamide fabric is that it can stretch. You can stretch it, and it will not lose its shape. This is a big plus for clothes, like workout clothes and swimsuits. Polyamide fabric is also light. It is good at moving sweat away from your skin. It also dries fast and does not wrinkle or shrink easily. But, it is good to know that pure nylon fabric does not let air pass through it easily. It can also melt if it gets too hot. That is why it is often mixed with other fibers to make it more comfortable to wear.

Nylon 6 is a very flexible polymer that works very well. It is one of the most common kinds of polyamide, and there is a good reason for that. It has a good mix of features that make it useful for many different things, from fabrics to parts for machines. One of the best features of Nylon 6 is that it is very tough. It can take a hit without breaking. This is very important for things like car parts and factory machines.

When we talk about being flexible, Nylon 6 is known for being stretchy. It can also be easily molded into different shapes. This flexibility is a big help when making things. It can be easily used in machines that use injection molding and extrusion. It does melt at a slightly lower heat than Nylon 6,6, but it is still very good at handling heat. It can be used in hot places. The mix of strength, flexibility, and toughness makes Nylon 6 a true high-quality polymer.

I think you can start to see why I like polyamide so much. It has many good things about it. This makes it a popular choice for many different kinds of businesses. One of the biggest good things is its high strength and toughness. This material is strong. It can handle a lot of use without wearing out. This makes it great for products that need to last a long time. Another good thing is that it resists rubbing. This is especially good for things that have a lot of rubbing, like gears or carpets.

Another big plus for polyamide is how flexible and stretchy it is. This feature is very important for fabrics. It allows for clothes that are comfortable and fit well. Being resistant to chemicals is another big benefit of polyamide. It can handle many different chemicals, oils, and fuels. That is why it is used so much in the car business. On top of all that, polyamide is light. This is a big help for things where weight matters, like in cars and airplanes. And for people who make things, polyamide is pretty easy to work with. This helps keep the cost of making things down.

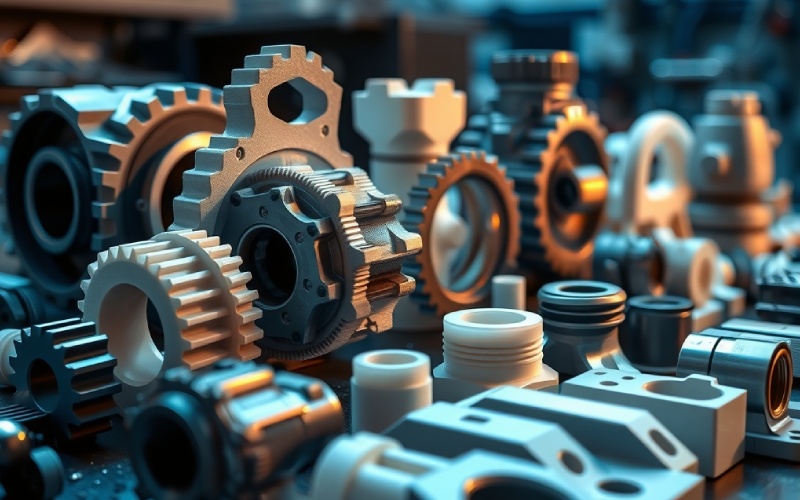

The ways to use polyamide are very different. It is used in many kinds of businesses. I already said it is used a lot in the fabric business for things like clothes, carpets, and ropes. But it is used for much more than that. The car business uses a lot of polyamide. It is used for many parts under the hood and inside the car. You can find it in engine covers, fuel lines, gears, and even in the containers for airbags. Because polyamide is light, it helps make cars weigh less. This helps cars use less gas.

In the world of things we buy, polyamide is almost everywhere. It is used to make the bristles on toothbrushes, tools for the kitchen, and packaging for food. Electronics makers also use polyamide because it does not let electricity pass through it. It is used in plugs, cables, and parts for circuit boards. And with 3D printing becoming more popular, polyamide is a common material for making strong and tough printed things. From factory uses like gears and bearings to things we use every day, there are so many ways to use this polymer.

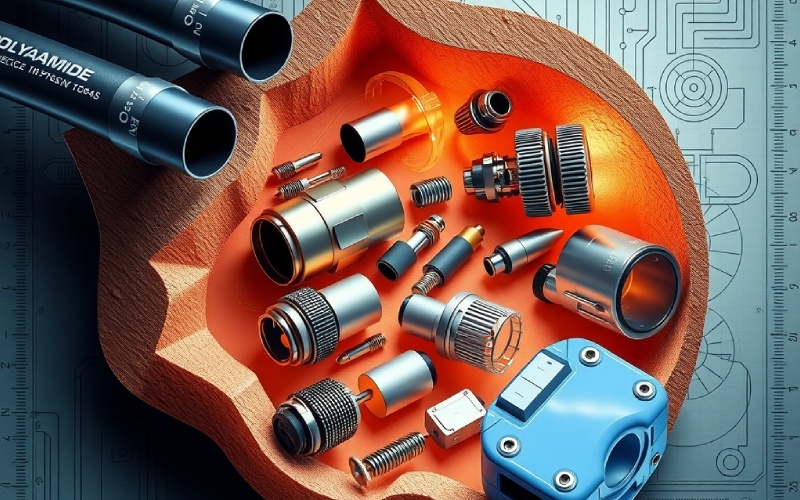

Regular polyamides like nylon 6 and nylon 6,6 are already great materials. But there is another group called high-performance polyamides (HPPAs). These are special kinds of polyamides that have been made to have even better features than the normal kinds. HPPAs are made to handle very tough situations. This includes very hot places, very wet places, and strong chemicals. They hold their shape better and are stronger. This makes them good for the toughest jobs.

One of the main differences between normal polyamides and HPPAs is in their structure at a tiny level. High-performance polyamides often have special rings in their polymer chain. This makes them stiffer, harder to melt, and better at resisting chemicals. These materials are often used to be instead of metal parts when making things lighter is important, like in cars and airplanes. They cost more than normal polyamides. But they work so much better that the higher price is worth it for jobs where things cannot be allowed to fail.

When we talk about high-performance polyamides, a name that always comes up is aramid. Aramids are a kind of aromatic polyamide. They are known for being very, very strong and good at handling heat. You have probably heard of the two most famous aramids: Kevlar and Nomex. These are brand names for aramid fibers made by the DuPont company.

Kevlar is probably the most famous aramid. It is famous because it is very strong but also very light. It is the material used to make vests that stop bullets. It is also used in parts for airplanes and other things where high strength and low weight are needed. Nomex is known for being very good at handling heat and fire. This makes it the perfect material for safety clothes for firefighters, race car drivers, and factory workers who are around high heat and flames. Aramids are a great example of how the basic polyamide structure can be changed to make materials with amazing features.