دع Istar يساعدك على البدء في مشروعك من خلال خبرتنا ودرايتنا!

قم بتحميل ملفات التصميم ومتطلبات الإنتاج الخاصة بك وسنعاود الاتصال بك في غضون 30 دقيقة!

The ISO 2768 standard is a simple set of rules that prevents problems like mis-specifying general tolerances. It tells a machine shop how exact a part needs to be, even if you don’t write a tolerance on every single dimension. This article will explain this powerful manufacturing standard in simple terms. You will learn how to save money, reduce errors, and make better parts that always fit.

Have you ever built something from a kit? The parts almost always fit together. This is because the people who made them followed clear rules. In professional work, especially in mechanical engineering, we need rules too. The ISO 2768 standard is one of those important rulebooks. ISO 2768 is an international standard. It was made by the International Organization for Standardization (ISO). This group creates rules so that things work the same way all over the world. This recognized standard helps ensure consistency.

The main job of this general standard is to simplify drawings. Instead of writing a specific tolerance for every single size, you can use a general note. This note tells the machine shop the default precision levels for the whole part. This saves a lot of time for designers. It also makes drawings cleaner and easier to read. When you use ISO 2768, you are using a system that machinists everywhere understand. This standard facilitates communication across different countries. It is a key manufacturing standard for anyone making physical parts.

The ISO 2768 standard is divided into two parts. The first part is called ISO 2768 part 1. This part deals with tolerances for linear and angular dimensions. Think of a simple block. It has a length, a width, and a height. These are its linear dimensions. If it has a sloped side, the angle of that slope is an angular dimension. ISO 2768 provides general tolerances for linear and angular sizes. This means it sets a default rule for how much these sizes can vary.

When you draw a part, you give it a perfect size. We call this the nominal size. But no machine can make a part perfectly. There will always be a tiny difference. This difference is called a deviation. ISO 2768 part 1 tells us the permissible deviation for different sizes. For example, for a nominal length of 50 mm, the rule might say the actual part can be between 49.8 mm and 50.2 mm. This allowed range is defined by the tolerance limits. The standard has tables, like Table 1, that list the allowed deviation for various linear and angular dimensions. This helps define the acceptable dimensional variation without needing individual tolerance indications on the drawing.

The second part of the standard is Part 2. This part covers geometrical tolerances for features. Size is not the only thing that matters. Shape and position are also very important for ensuring that parts fit and work correctly. Part 2 of the standard helps define these shape rules. These rules are a simple form of geometric dimensioning and tolerancing. They make sure the features on a part are made correctly.

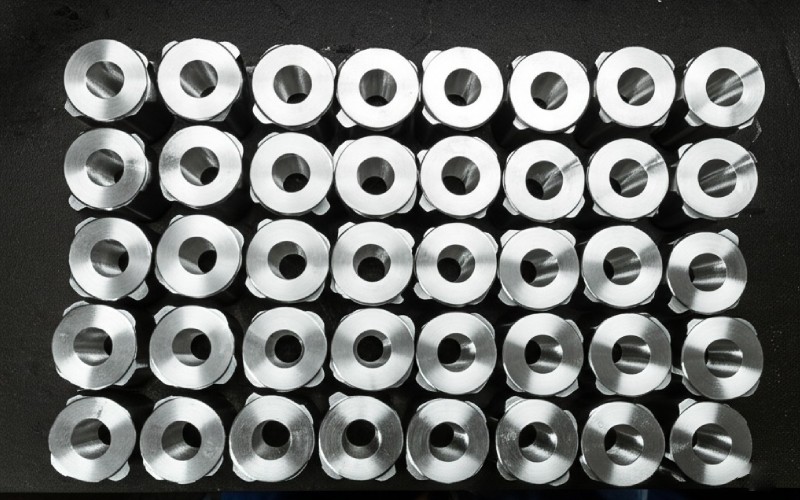

Imagine a long, straight pin. Part 2 sets a general tolerance for its straightness. This means the pin cannot be too bent. Now imagine a flat plate, like our compressor base. This rule sets a general tolerance for its flatness, so it can’t be warped. It also covers things like perpendicularity, which means making sure two surfaces are at a perfect 90-degree angle to each other. Other rules include symmetry, to ensure a part is balanced around a center line or axis, and circularity tolerance, to make sure a hole is truly round. These geometric rules are crucial for parts that need to move, seal, or connect precisely. The allowed deviation for flatness or straightness is very important.

The ISO 2768 standard is not a one-size-fits-all rule. It gives you choices. It has four tolerance classes. These classes let you pick the right level of precision for your part. The classes are: ‘f’ for fine, ‘m’ for medium, ‘c’ for coarse, and ‘v’ for very coarse. Choosing the right tolerance class is a key decision in the design and manufacturing processes.

Your choice of tolerance class depends on the job the part does. If you are making a high-precision part for an airplane engine, you might choose the “fine” tolerance class. This means the allowed deviation from the nominal size is very small. But this high precision costs more money to machine. If you are making a simple bracket or a cover, a “medium” or “coarse” tolerance class is usually good enough. The deviation can be larger, which makes the part easier and cheaper to make. For non-critical features, the “coarse” tolerance class is often the best balance of cost and function.

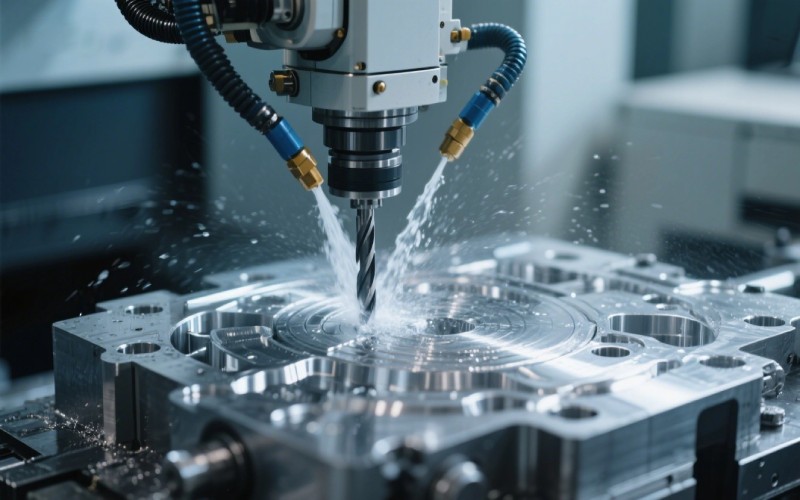

Let’s look closer at the different precision levels. The four tolerance classes provide different tolerance ranges. The “fine” class has the smallest tolerance ranges. It is for parts that must fit together very tightly. The “medium” class, often written as “medium”, is the most common. It offers a good balance and is typically used for many general mechanical engineering applications. The general tolerance here is good for most parts made with modern CNC machining.

The “coarse” tolerance class allows for a larger dimensional deviation. This is useful for parts where the exact size is not critical, like a rough casting or a simple support structure. A coarse tolerance class can save a lot of money. Finally, the “very coarse” class has the largest tolerance ranges. It is used for parts where the final dimensions will be set by a later process, or where the fit is very loose. Each tolerance class has specific tolerance values for different nominal sizes and linear and angular dimensions. The allowed deviation for a coarse part is much bigger than for a fine one.

Applying ISO 2768 is very easy. You do not need to write a lot. All you need to do is add a single note in the title block of your technical drawing. This note tells the machinist which general tolerance standards to follow. A common note looks like this: ISO 2768-mk. This simple specification gives the machinist a huge amount of information.

Let’s break down that note. ISO 2768 is divided into two parts, and the note reflects that. The “m” refers to Part 1, for linear and angular dimensions. It tells the machinist to use the “medium” tolerance class. The “k” refers to Part 2, for geometrical tolerances for features. The geometric classes are H, K, and L. Class K is a common choice. So, ISO 2768-mk means “use the medium tolerance class for sizes and the K tolerance class for shapes like flatness and straightness.” This is how you specify the general tolerance for the whole part. This simple act of tolerancing prevents so many problems.

For a company that makes parts, achieving ISO compliance is a big deal. While a shop isn’t “certified” in ISO 2768 in the same way as ISO 9001, showing they follow it is very important. It shows they are committed to quality. When a machine shop says they work to the ISO 2768 standard, it tells customers that they understand and can meet global tolerance requirements. It builds trust.

This is especially important when parts are produced by different manufacturers. If a designer in one country sends a drawing to a shop in another, the ISO 2768 standard acts as a common language. It helps ensure consistency. The shop knows exactly the level of quality needed without asking lots of questions. This makes getting quotes easier and reduces mistakes. For any shop doing CNC machining, following this recognized standard is a sign of professionalism. It is a key part of ensuring that parts meet the required specification.

Imagine a compressor base that is a flat plate with four holes and a small angled edge, or chamfer. On the drawing, we write ISO 2768-mk. The plate has a nominal length of 300 mm. The machinist looks at the ISO 2768-m table. For a nominal size of 300 mm, the table might show a permissible deviation of +/- 0.5 mm. This means the final part can be between 299.5 mm and 300.5 mm. The machinist doesn’t need us to write that on the drawing.

Now, let’s look at the flatness of the compressor base. Because we specified “k” for the geometric tolerance class, the machinist looks at the Part 2 table. For a 300 mm part, the table might say the flatness deviation must be within 0.4 mm. This means the entire surface must lie between two imaginary parallel planes that are 0.4 mm apart. The same idea applies to the straightness of an edge or the perpendicularity of a corner. This general tolerance on the compressor base ensures it will sit flat and work correctly. The deviation for the chamfer angle is also covered by the angular dimensions in technical drawings section.

Yes, there are other tolerance standards in the world. The most common one you might see is from ASME (the American Society of Mechanical Engineers). The ASME standards are used a lot in the United States. There are some standards similar to ISO 2768 that also provide rules for tolerancing. They all try to solve the same problem: how to specify tolerances clearly and simply.

However, 2768 is an international standard from the International Organization for Standardization. This means it is used and understood all over the world. This is a huge advantage. If you are designing a machine or a product that will be sold or made in different countries, using ISO standards is the safest bet. It helps in ensuring that parts made by different suppliers or manufacturers will fit together properly. While other general tolerance standards exist, ISO 2768 is one of the most widely accepted for general tolerancing.

It is easy to implement ISO 2768. The first step is to decide on a default tolerance class for your company. For most general work, ISO 2768-mk is a great starting point. It provides a good balance of precision and cost. You get a medium dimensional tolerance class and a solid geometric tolerance class. This covers your linear dimensions, flatness, straightness, and perpendicularity.

Next, you should update your company’s drawing templates. Add the chosen ISO 2768 tolerancing note to the title block. This makes it the default for all new designs. It is also important to train your designers and engineers. Make sure they understand what the tolerance class means and when they might need to specify a different tolerance for a special feature. ISO 2768 helps simplify drawings, but it doesn’t replace the need for careful thought. By making it a standard practice, you make your whole design process more efficient and reliable.