دع Istar يساعدك على البدء في مشروعك من خلال خبرتنا ودرايتنا!

قم بتحميل ملفات التصميم ومتطلبات الإنتاج الخاصة بك وسنعاود الاتصال بك في غضون 30 دقيقة!

I’ve worked with lots of stuff for a long time, and sometimes, I find something really special. Mylar is one of those things. you’ve probably seen it and didn’t even know. It’s in shiny birthday balloons, the silver inside of a chip bag, and even in emergency space blankets. But what is this useful plastic film? In this article, I’ll tell you my stories and everything i learned about the cool things Mylar can do, how it’s made, and why its used in so many ways. Reading this will help you see this regular stuff in a new way.

The first time I used Mylar I was looking for a tough material for a job. I learned fast that “Mylar” is a brand name for a certain kind of polyester film. The real name for this stuff is biaxially-oriented polyethylene terephthalate. Or you can just say BOPET for short. It’s a long name, i know! It is basically a special plastic sheet made from PET. That’s the same plastic in water bottles. But, the way Mylar is made gives it some really neat powers that make it different from other plastic.

The word Mylar is now used for almost any shiny plastic film. It’s like how people say “Kleenex” for any tissue. This useful material is known for its high tensile strength. that means it can stretch a lot and not break. It is also safe around chemicals, a great electrical insulator, and you can see through it or make it shiny. Over the years, I’ve seen this plastic film used in tons of applications, from simple food package to tricky electronic parts. The reason Mylar is so widely used is because it has all these special properties together.

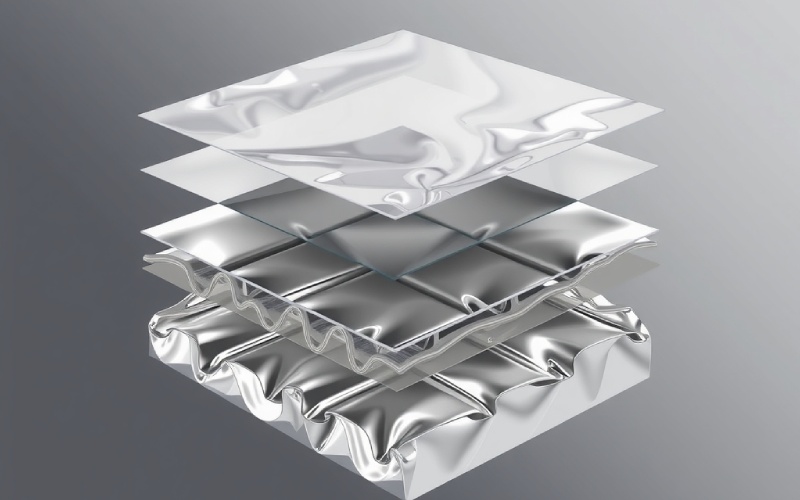

The way Mylar is made is what gives it its awesome strength. I thought it was super interesting when I learned how they do it. It starts by melting down polyethylene terephthalate (PET) plastic. This hot liquid plastic is then made into a thin film, usually on a cold roller to cool it off. This first plastic sheet is only the start.

What they do next is the secret to Mylar’s strength. The film gets stretched in two ways. this is called biaxial orientation. It’s kind of like stretching pizza dough but with big machines. The film is first pulled one way with rollers. Then it gets stretched the other way, the transverse way. This stretching lines up the tiny plastic parts, which makes the film’s tensile strength much better. After stretching, the film is heated up to keep the tiny parts in place. This makes sure the Mylar film keeps its shape and strength. This is how a simple PET plastic turns into the tough Mylar we see in so many things.

Ever ask yourself why your chip bag keeps the chips fresh? You can thank Mylar for that. I have done work on a few food package jobs, and Mylar is almost always the first pick for a good reason. Its great barrier properties are what make it so great for the food packaging industry. Mylar film does not let gases, like oxygen, pass through it as easy as other plastics. This is super important because oxygen is what makes food go bad.

When Mylar is used for a food package it often has a super thin layer of metal, like aluminum, put on it. They do this with a thing called vapor deposition. This metal-coated polyester film makes an even better barrier against wetness, light, and air. This helps food last longer on the shelf. You’ll find Mylar in lots of food packaging, like coffee pouches and yogurt lids and snack bags. The power of a Mylar bag to make a good seal and keep stuff safe makes it a perfect pick for keeping food fresh.

| Food Package Use | Why Mylar is Good |

|---|---|

| Coffee Bags | Great block for air and wetness, keeps it fresh and smelling good. |

| Snack Food Bags | Keeps snacks crunchy and stops them from getting stale. |

| Yogurt Lids | Makes a strong seal and keeps germs out. |

| Storing Food Long-Term | Makes an airtight and dark space to keep food good for years. |

Those shiny, fun balloons you see at a party are another common use of Mylar. I was always wondering why they use Mylar for balloons and not just plain plastic. The big reason is it can hold helium for a very long time. A Mylar balloon is made from a thin sheet of Mylar film. It is coated with a layer of metal which gives it that shiny look. This metal layer also makes the balloon leak less. So the small helium bits can’t get out as fast as they do from a normal balloon.

Making a Mylar balloon is pretty cool. The Mylar film is printed with a picture, cut into a shape, and then two pieces are heated together to make the balloon. A special valve is also put in to make blowing it up easy. The high tensile strength of the Mylar film lets the balloon be filled with lots of helium and not pop. This is why a helium-filled balloon made from Mylar can float for many days. That makes them a very popular pick for parties.

Besides food and fun Mylar has some big jobs in industry. especially as an insulator. From my time working with electronics, I can tell you Mylar is a top-notch electrical insulator. It has a high dielectric strength. that means it can handle a lot of electricity before it fails. This property makes it perfect for use in things like capacitors, transformers, and to cover wires. The plastic film is thin, flexible, and strong so it can be used in lots of electrical applications where there is not much room.

Mylar is also a good thermal insulator. You probably know about emergency “space blankets.” these are made from a super thin sheet of Mylar with a shiny metal coat. This reflective material is made to bounce thermal heat. That is a big way our bodies lose heat. By bouncing up to 90% of a person’s body heat back to them these blankets can save a life when it’s cold. This same shiny property is used for insulation in houses, tents, and even space suits.

The Mylar story goes back to the middle of the 1900s. I think the history of things is really neat, and Mylar’s story is a great one about new ideas. The plastic it’s made from, polyethylene terephthalate (PET), was first made in the 1940s. The way to make the strong, stretched version of this plastic film known as BOPET, was made in the mid-1950s by a few companies, like DuPont, Imperial Chemical Industries (ICI), and Hoechst.

DuPont was a big part of this work, and they got the brand name Mylar in 1952. It was a big time for plastic science and Mylar fast found a lot of uses because of all its special properties. From being used early by Kodak for new film to its job in NASA’s first space satellite, Mylar has a long history of being part of new tech. Today, the Mylar trademark is owned by DuPont Teijin Films.

For sure! Food packaging and balloons are some of the uses you see most, but Mylar is used for way more than that. I am always amazed by the new and smart ways people use Mylar. Here are a some more examples:

This useful plastic film is really a master of all trades in the world of materials. Its special mix of strength, safety, and blocking powers makes it a great part of many different consumer and industry items.

The famous shiny, metal look of many Mylar things comes from something called metallization. I’ve always been amazed by how a plain plastic film can be made to look so shiny. The way its done usually uses physical vapor deposition (PVD). in this process a metal, usually aluminum, is turned into a gas inside a room with no air. This metal gas then cools and sticks to the Mylar film. This makes a super thin, even layer of metal.

This metal coat is what gives Mylar its high reflectivity. It also makes its barrier powers against gas and wetness even better. The shiny kind is very common but Mylar can also be made clear or with a flat, not shiny, look. The fact that you can change the look of the Mylar film makes it even more useful. It can be used in lots of applications where you need a certain look or power.

When I pick a plastic film for a job I have to think about what the job needs. Mylar, or BOPET, has some good points over other normal plastics. For example, next to something like PVC, Mylar has better tensile strength and it can handle heat better. It also resists chemicals better than lots of other plastics. This makes it a stronger pick for tough places.

For insulation, Mylar is sometimes put next to stuff like fiberglass. Fiberglass is known for being strong but Mylar is lighter and you can bend it more. this makes it easier to use for some jobs. Mylar also is better at blocking wetness which is a big plus in places where water drops could be a problem. The special mix of high tensile strength, chemical safety, and great barrier powers makes Mylar a better pick for many tough applications in many industries.

After using Mylar for a lot of years, I’ve really grown to like how useful it is. It’s a material that does a big job in our lives without us knowing it. From keeping our food good to making parties more fun, the uses for this great plastic film just go on and on. The next time you see a shiny balloon or open a bag of coffee, you’ll know the smarts and new ideas that went into making that simple package.

To wrap it all up, here are the biggest things to remember about Mylar: