Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

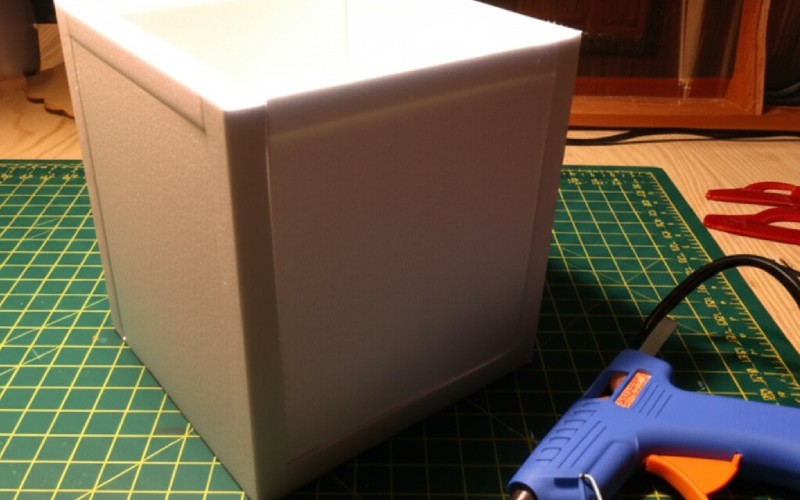

In this article, I will show you the simple techniques to create strong, clean foam core projects, like a perfect box. Reading this article will save you time and frustration.

Foam core is a wonderful material for any craft project. It is made of a layer of foam pressed between two layers of paper or card. Think of it like a sandwich. The foam is the filling, and the paper is the bread. This simple construction makes the board light but also strong.

You can find foam core at most craft stores. You can even find it at a dollar store, which makes it a very cheap option. This material is great for making models, building inserts for a board game box, or for school projects. It is also used for professional printing displays because it is so light and flat. The overall value you get from this cheap material is amazing.

Before you start any project, you need the right tools. You do not need anything expensive. The most critical tool you will need is a very sharp knife. A simple craft knife or a utility knife will do. The key is the blade. It must be sharp. A dull blade will tear the foam and paper, making a messy edge.

You will also need a metal ruler and a cutting mat. A ruler is a must-have guide for making a straight cut. I prefer a metal ruler because a plastic one can be cut by your knife. A cutting mat protects your table. It also helps you hold the board in place. Having the right tool makes the process much easier. This basic setup is all you need to start building with foam core.

Getting a clean, straight cut is the most important skill. It is the foundation of all good foam core construction. Never try to cut through the board in one pass. This is where most people go wrong. They push too hard and the knife slips, or the edge gets crushed. This is a bad technique.

Here is the right technique. First, line up your ruler where you want to cut. Hold it down firmly. On your first pass with the knife, use light pressure. Your goal is only to cut through the top layer of paper. On your second pass, go a little deeper to cut the foam. On the third pass, cut through the bottom layer of paper. This method gives you a perfect, clean edge every time. Always use a fresh, sharp blade.

The easiest way to join two pieces of foam core is with a butt joint. This is the most basic joint you can make. You simply take the cut edge of one piece and glue it to the face of another piece. This creates a simple corner. It is a quick way to connect a panel.

To make this joint, run a thin line of glue along the edge of one piece of foam core. Then, press it against the other piece and hold it still until the glue sets. While this is a simple technique, it is not the strongest joint. The connection relies only on the glue. For a small box or a light application, it works fine. But for a stronger build, you will want to use a better method.

If you want to create a much stronger joint, you should learn the rabbet cut. This technique creates a stronger mechanical connection between the two pieces. It makes your building projects much more durable. A rabbet joint looks clean and professional.

To make this cut, you need to remove some of the foam from the edge of a piece. First, measure the thickness of your foam core board. Let’s say it is 3/16 of an inch thick. You will make a cut that same distance from the edge of the piece you want to join. Cut through the first layer of paper and the foam, but do not cut the bottom paper layer. Then, make a second cut from the edge of the board into the foam to meet your first cut. You can then easily remove the strip of foam. This leaves a flap of paper that you can glue over the other piece, creating a very strong corner.

For the cleanest possible corner on a box, the best technique is a miter joint. This involves cutting the edge of each piece at a 45-degree angle. When you join two pieces cut this way, they form a perfect 90-degree corner. The paper from both sides meets perfectly, so you do not see the foam edge at all.

To do this, you will need a special tool or a very steady hand. Some craft knife sets come with a guide for cutting at an angle. Alternatively, you can tilt your knife as you cut along your ruler. This technique takes some practice. The result is a very professional-looking corner for your box. This approach is great when the look of the final piece is important.

The type of glue you use can make a big difference. The two most common choices are hot glue and white craft glue, also called PVA glue. Your choice will depend on your specific application and how much time you have.

A hot glue gun is a popular tool because the glue sets very fast. This is helpful because you do not have to hold the joint for a long time. However, hot glue can be messy. It can also be too hot and melt the foam inside the board. Use a low-temp glue gun if you choose this option. White craft glue creates a stronger, cleaner bond. It does not damage the foam material. The only downside is that you have to hold the joint together while the glue dries.

Let’s use what we learned to build a simple box. Good planning is the first step. Decide on the dimension of your box. Let’s say you want to make a 4-inch cube. You will need to cut six squares that are 4 inches by 4 inches. But wait! You must account for the thickness of the foam core board.

For a strong box, use the rabbet joint technique we talked about. For the bottom piece of the box, you do not need to change its dimension. For the four side pieces, you will need to cut rabbet joints on the edges that will connect. When you cut your pieces, be very precise. A small error in your cut can make the box look crooked. Apply glue to the joint, press the pieces together, and hold them. Building a box is a great way to practice.

Once you are familiar with the basics, you can try some advance techniques. Foam core is not just for straight lines and boxes. You can create curves. To do this, make a series of small cuts on one side of the board, only through the paper layer. Do not cut the foam or the other side of paper. This will allow the board to bend easily into a smooth curve.

For a larger or heavier project, you might need to make your joints even stronger. One way to do this is to add extra support. You can glue a small strip of card or paper over the inside of a joint. You can also use tape on the outside of a corner for additional strength. These little tricks can help you create bigger and better things with this simple material.

Most of the time, people get frustrated with foam core for a few common mistakes. The number one mistake, by far, is using a dull blade. I cannot say this enough: use a sharp knife! Change your blade often. A fresh blade makes a clean cut. A dull blade tears the paper and foam.

Another common mistake is using too much glue. A thick glob of glue does not make a stronger joint. In fact, too much glue can make the paper wet and weak. It also squeezes out and makes a mess. You only need a thin, even line of glue. Apply just enough to stick the two surfaces together. Avoid these mistakes, and your building experience will be much better.