Lad Istar hjælpe dig med at komme i gang med dit projekt med vores erfaring og knowhow!

Upload dine designfiler og produktionskrav, så vender vi tilbage til dig inden for 30 minutter!

A milling machine is a very important tool for making parts. Picking the right one for a job is a big deal. In this post, I will share what I have learned. I will explain the differences between horizontal and vertical and horizontal milling in a very simple way. You will find out which machine is the best choice for different types of work.

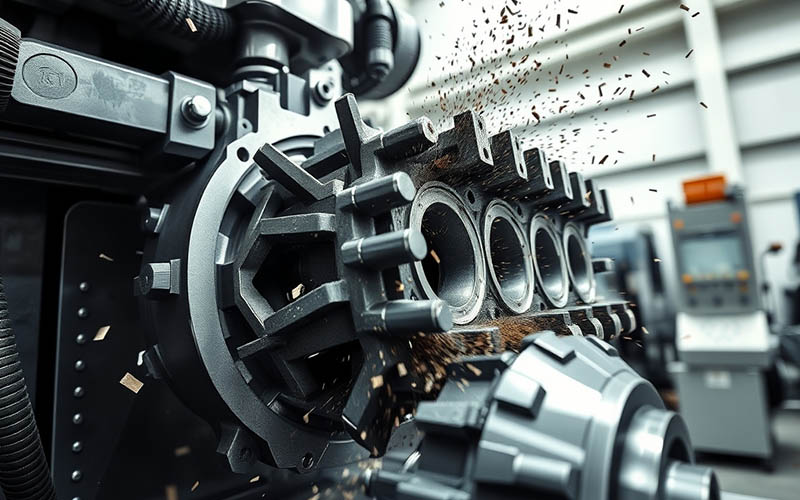

Let’s begin with the simple facts. A milling machine is a tool you see in many workshops where things are made. Milling is a common way of making things. Its most important job is to cut metal and other hard materials. You can think of it as a very strong and exact carving tool. The machine uses a spinning cutting tool. This tool is used to remove material from a stationary workpiece. A workpiece is simply the block of material you are cutting into a shape.

The way this tool removes material is easy to understand. A sharp cutter on the milling machine spins around very fast. While it spins, it cuts off small pieces of the material, which are called chips. You can move the workpiece back and forth. This lets you cut it into the perfect shape you need. This method allows you to create many different things. You can make simple blocks or very detailed parts for things like engines or electronics. Every mill works using this main idea. But, how they do it can be very different. The two types of milling machines are the vertical mill and the horizontal mill.

If you ask someone about horizontal vs vertical milling, the first thing they will mention is the spindle. The biggest difference between these two kinds of machines is the direction the spindle points. This is called the orientation of the spindle. The spindle is the part of the machine that holds the cutting tool and makes it spin. You could say it is the most important part of any mill.

In a vertical mill, the spindle has a vertical orientation. This just means it points straight up and down. The cutting tool can move up and down, and from side to side. In a horizontal mill, the spindle has a horizontal orientation. It is set up flat, in the same direction as the floor. The difference between the two types might not sound like a big deal. But it changes everything about how the machine cuts. It also changes what kinds of jobs the machine is good for. This simple change in direction is the main reason for all the differences between horizontal and vertical milling machines.

On a vertical mill, the spindle containing the cutting tool is aimed down at the work table. The tool can go up and down. The table holding the workpiece can move left and right, and also forward and backward. Because the tool is pointed down, it is very easy for the person using the machine to see what is happening. This makes a vertical mill a great choice for jobs that need very careful work.

You can use a vertical mill to drill holes, cut a groove, or make surfaces flat. Because the spindle is set up vertically, it is perfect for making pockets and other shapes on one side of a part. I often choose a vertical machine when I have to work on small parts or special projects that I only make once. Setting it up is usually easier when compared with a horizontal mill. It is a very common milling machine for people to learn how to use. This kind of mill is a top choice for many small workshops.

Yes, there are a couple of types of vertical milling. The two types of vertical machines you will see the most are the turret milling machine and the bed mill. These two types of vertical mill machines have some small differences in how they work.

The most common kind is the turret mill. People sometimes call it a vertical knee mill. On these turret milling machines, the spindle does not move from its spot. Instead, the table moves both side to side and up and down. This gives you a lot of control over the cut. It gets its name from the turret, which lets the vertical head of the mill turn. This makes it useful for even more jobs.

The other main kind is the bed mill. On bed milling machines, the table only moves in two directions, forward and back. The spindle itself moves up and down and from side to side to do the cutting. These machines are often larger and stronger than a turret mill. They are good for handling a much heavier workpiece. A vertical mill can also be a CNC vertical milling machine, which means it is guided by a computer program.

Now, we can talk about the horizontal mill. Like I said before, this milling machine has its spindle set up flat. The cutting tool comes out from the side of the machine. The tool often looks like a few saw blades stacked together. It can rotate on a long bar. This horizontal setup allows the cutter to make very different kinds of cuts than a vertical one.

On a horizontal mill, the table moves up and down and side to side. It lifts the workpiece into the spinning cutter. Because the spindle is sideways, a horizontal mill can use larger cutting tools that are better supported. This design makes the horizontal mill very strong and steady. It is made for tough jobs. This is a very powerful machine.

The horizontal mill has some great strengths. First, horizontal milling machines feature better chip removal. This means the small bits of metal that are cut away just fall down. The horizontal cutters throw the chips away from the part being cut. This is very good because it keeps the cutting area clean. It also helps the cutting tool stay sharp for a longer time.

Second, a horizontal mill is much better for making deeper cuts. The tools used on this machine, or horizontal tools, are usually shorter and thicker. Because the tools are thicker, they are much stronger. These machines have shorter and thicker tools that do not bend easily. This lets the horizontal mill remove material more quickly. This is known as a higher material removal rate. This makes the horizontal milling machine perfect for jobs where you need to take off a lot of metal fast from many workpieces. Horizontal milling machines perform very well on jobs where many of the same part are made.

A vertical mill is often the better machine for some types of jobs. The best thing about a vertical mill is that it can be used for many different jobs. Because it is easy to see the workpiece and the cutting tool, it is perfect for projects with parts that have a lot of small details on one side. You can think of it like writing with a pen. It is simpler to see what you are doing when you can look down at your work.

I use a vertical mill for jobs that are like carving a shape into a block. It is also very good for drilling holes in exact spots. Vertical machines are also usually cheaper and do not need as much space as horizontal counterparts. For a small machine shop or for making just one part, a vertical milling machine is often the choice that makes the most sense. It is a great all-around machine. This is why the vertical mill is so well-liked.

You may be asking if you have to pick between a vertical or horizontal mill. The good news is some machines can do both jobs! These are usually called universal milling machines. They have a table that can turn at an angle. They also have a special head that can be set up either vertically or horizontally.

These machines often have a turret that lets you change the head of the mill. This means you can get the benefits of both vertical and horizontal milling all in one machine. These are very helpful, but they can be harder to get ready for a job. You can do a milling operation with either a vertical orientation or a horizontal orientation. For shops that do many kinds of projects, a universal mill can be a good thing to spend money on.

So, how do you pick one? Choosing between vertical or horizontal milling really depends on the work you need to do. You must think about the shape of the part, how many parts you have to make, and what kind of cuts you will make. The cutting specifications and results will not be the same for each machine. Here is a simple chart to help you pick.

| Funktion | Vertikal mølle | Vandret mølle |

|---|---|---|

| Spindle Axis | Vertical (up and down) | Horizontal (side to side) |

| Bedst til | Single, detailed parts, small parts | Many sides, heavy parts, making many parts |

| Synlighed | Great, easy to see the cut | Can be hard to see the cut |

| Omkostninger | Usually costs less | Usually costs more |

| Common Jobs | Drilling, making slots, facing | Heavy cuts, making a groove, slitting |

| Chip Removal | Chips can build up | Great, chips fall away |

| Værktøj | Longer, thinner tools | Shorter and thicker tools |

Looking at this chart, if you need to make one side of a part with a lot of detail, a vertical mill is a smart choice. If you have to make a lot of parts and make deeper cuts on different sides, a horizontal mill will get the job done faster and better. Understanding the differences between horizontal milling machines and their vertical counterparts is very important.

From what I have seen, you will find a vertical mill in almost any machine shop. They are more popular because they can be used for so many jobs and cost less money. The well-known vertical knee mill is a very common machine in tool rooms, repair shops, and small workshops everywhere. Many people learn about CNC-bearbejdning by using vertical machining centers.

Horizontal mill machines are scarce in smaller shops. You are more likely to find a horizontal milling machine in big factories where they do a lot of work making many of the same part. It takes more skill to use a horizontal mill, so you need more expertise in the horizontal milling methods. Even though you see fewer of them, for the right kind of big, heavy-duty job, a horizontal mill is the very best machine to use. The milling process on these machines works quickly and well.

I hope this helped you learn about horizontal and vertical milling machines. It might seem like a lot, but the main points are simple. Here are the most important things to keep in mind from our look at milling machines and vertical milling: