Lad Istar hjælpe dig med at komme i gang med dit projekt med vores erfaring og knowhow!

Upload dine designfiler og produktionskrav, så vender vi tilbage til dig inden for 30 minutter!

I’ve worked for a long time in the plastic and rubber business, so I’ve seen many types of materials. Two that have always been around are Thermoplastic Rubber (TPR) and Polyvinyl Chloride (PVC). At first glance, they look alike – they’re both plastics and can both be bendy. But if you look closer, you’ll see they are very different. Knowing these differences is very important for people who design or make products, or even if you’re just curious about the world. In this article, I’ll share what I’ve learned over many years in a simple guide. We will look at the details of TPR vs. PVC, from how they are built to how they are used, so you can choose the right material for your job.

From my experience, Thermoplastic Rubber (TPR) is a very interesting material. It’s a man-made rubber that nicely mixes the bendiness of rubber with the easy shaping of plastic. It’s like a mix that gives you the best of both. TPR is a type of thermoplastic elastomer (TPE), and it’s usually made from a material called Styrene-Butadiene-Styrene (SBS). How it’s built is why it works the way it does. The styrene part means it can be melted and used again, while the butadiene part gives it that stretchy, rubbery feel.

Making TPR is done in a complex way called living anionic polymerization. In this process, small parts of styrene and butadiene are joined to make the SBS polymer. This creates a structure with hard parts and soft parts. This special build is what gives TPR its normal rubbery feel and action. The basic stuff is made into small beads, which are then used in different making processes like injection molding and extrusion. A great thing about TPR is that, different from old-style rubbers, it doesn’t need to be hardened with heat or chemicals. This saves time and energy when making things.

You can change how TPR acts for different needs by changing the mix of styrene and butadiene. More styrene makes it harder, while more butadiene makes it softer and more bendy. This ability to change is a big reason TPR is used in so many different things in many businesses.

Now, let’s talk about Polyvinyl Chloride, or PVC. It’s one of the most common man-made plastics in the world, and there’s a good reason for that. I’ve worked with PVC my whole career, and it’s amazing how it can be used for so many things. PVC is made through the polymerization of vinyl chloride monomer (VCM). Most PVC is made using a suspension polymerization process, where VCM is mixed in water and then turned into a plastic.

What you get is a hard, white solid, either as a powder or small grains. To make it useful for many different jobs, it’s mixed with other things called additives. These additives are what give PVC all its different qualities. For example, plasticizers are added to make PVC bendy, changing it from a hard to a soft material. Other additives include things to protect it from heat, make it slippery, or fill it out to improve it.

PVC has two main types: hard and soft. Hard PVC, often called RPVC or uPVC (unplasticized polyvinyl chloride), is strong and lasts a long time, making it perfect for things like pipes, window frames, and building parts. Bendy PVC, on the other hand, is used for things like electrical cable insulation, floors, and things you blow up. Being able to change it so much by adding things has made PVC a very important material for many businesses.

When you get down to it, you usually pick between TPR and PVC based on what they are naturally like. I’ve spent a lot of time looking at information and testing them, and here is a simple list of what I’ve learned:

| Kvalitet | Thermoplastic Rubber (TPR) | Polyvinyl Chloride (PVC) |

|---|---|---|

| Bendiness and Stretch | Very bendy and stretchy, bounces back well. | Can be made bendy with additives, but not as naturally stretchy as TPR. |

| Styrke | Stands up to use very well. | Also strong, but can get breakable after a while, mostly when it’s cold. |

| Hårdhed | Comes in many hardnesses, from very soft to kind of stiff. | Can be hard or soft, depending on the mix. |

| Heat and Cold | Works in a bigger range of heat and cold, usually -40°C to 120°C. | Works in a smaller range of heat and cold, usually -10°C to 60°C. |

| Kemisk modstandsdygtighed | Stands up well to many chemicals, like oils, solvents, and acids. | Stands up great to lots of chemicals, especially acids, alkalis, and salts. |

| Pulling Strength | Good strength when pulled, can stretch without tearing. | Its pulling strength is very different for the hard and soft types. |

One great thing about TPR is it can bend over and over without breaking. That’s why it’s used so much for shoe soles. It can be bent again and again without a problem. PVC is strong, but it isn’t as stretchy and doesn’t bounce back as well. When you add a plasticizer to PVC, it can also get brittle after a while as the plasticizer leaks out.

When it comes to making things, there are some important differences in how we work with TPR and PVC. The way the basic materials are made is very different. TPR is made by a process of living anionic polymerization of styrene and butadiene. But PVC is made by the polymerization of vinyl chloride monomer.

When turning these materials into finished things, you can use normal plastic-making ways like injection molding and extrusion for both. But, there are some small differences. TPR is usually easier to work with because it melts easily and doesn’t need the special setup that old-style rubber needs. Making things with TPR is quick and easy and can be done on regular plastic-making machines.

Working with PVC, especially the bendy kind, can be a little harder because you have to mix things in just right. You also have to watch the heat carefully when working with PVC. Getting it too hot can make it break down and let out harmful gases, which is bad for the machines. Injection molding for TPR is simple, where melted material is pushed into a shape to make detailed parts. Extrusion is used to make long shapes like tubes from both materials.

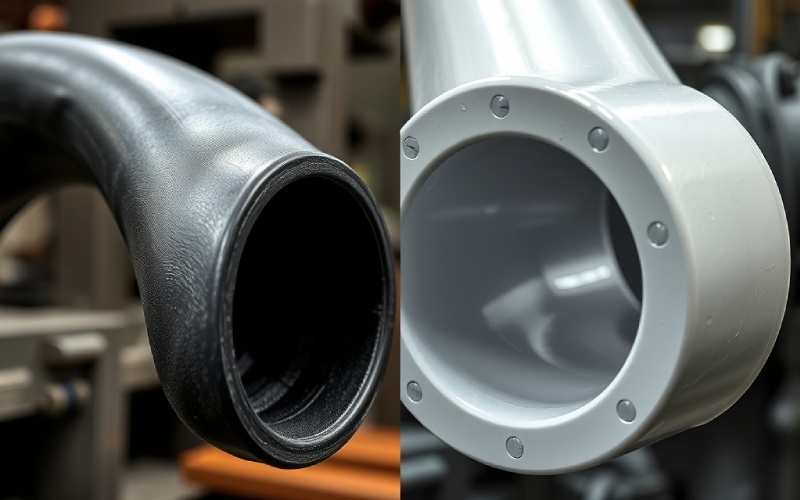

I get this question a lot. For jobs that need a lot of bend and stretch, TPR is usually the better pick. Its natural rubbery feel lets it stretch and go back to its first shape without getting damaged. This makes it perfect for products that get bent over and over, like the soles of a shoe, seals, and gaskets.

Flexible PVC is useful for many things, but it’s not as stretchy as TPR. It’s bendy because of added plasticizers, and like I said before, these can leak out after a while. This makes it less bendy and it might crack. Still, flexible PVC is a good pick for things like tubes, hoses, and cable insulation where being cheap and good against chemicals is a big plus.

I’ve often seen TPR used for tough jobs where you need it to last a long time and stay bendy. For example, in car parts like weather stripping and seals, TPR is a choice you can count on for a long time. For a basic garden hose, flexible PVC might be fine. But for a strong, bendy pipeline that needs to handle changing temperatures and high pressure, TPR would be the stronger choice.

When you need something hard and strong, rigid PVC, or uPVC, is definitely the best. Without those softeners, PVC is naturally a hard plastic with great strength that lasts a long time. This makes it a top choice for building, where it’s used a lot for pipes, fittings, window frames, and other building parts. I’ve seen PVC pipe systems that have worked for many, many years with no problems, which shows how well it lasts and resists rust and decay.

TPR is just naturally a bendy material. You can make it harder, but it’s not as stiff as uPVC. It’s just not made for jobs that need to be super strong. For instance, you wouldn’t make a high-pressure water pipe from TPR.

The strength and stiffness of uPVC also make it a good choice for things like storage tanks and the lining of chemical processing equipment, where the fact that it doesn’t break down from chemicals is also a big help. When you need something strong that won’t be hurt by chemicals, rigid PVC is often the cheapest good option.

How a material handles chemicals is very important for many jobs, and this is another area where TPR and PVC are different. Both materials are pretty good with chemicals, but PVC is usually better, especially against more types of chemicals.

PVC is great at standing up to acids, alkalis, and salts. That’s why it is used a lot in the chemical business for pipes, storage tanks, and linings. Hard PVC is especially known for being great at not corroding, making it a good substitute for older materials like steel in many jobs.

TPR is also good against many things, including oils, solvents, and some acids. This makes it good for things like automotive seals and gaskets, where it might touch different liquids. However, it might not be as good against as many chemicals as PVC. When I pick a material that will be around strong chemicals, I always check the information sheets from the company that sells it to make sure I’m picking the right one.

Both TPR and PVC are very useful materials that are used in a lot of different businesses.

TPR is often used for:

PVC, however, is a big deal in:

The material chosen for each job depends on what it needs to do. For example, in the shoe business, the comfy, bendy feel of TPR makes it better for shoe bottoms than the stiffer PVC.

Today, how materials affect the planet is a big deal. Both TPR and PVC are thermoplastics, which means you can melt them and make them into something new. So, in theory, you can recycle them. But actually recycling them is more complicated.

People usually think TPR is better for the environment than PVC. It’s easier to recycle, and the process is not as messy. Recycling TPR usually means chopping it up into small beads that can be used to make new things. People are also trying to create ways to recycle it with chemicals.

Recycling PVC is harder. You can recycle it, but the process is tricky because of the extra stuff mixed in and the chlorine it contains. When you burn PVC, it can let out bad chemicals called dioxins, which are a big problem for the environment. However, there are systems in place to recycle PVC, and you can do it many times.

In my opinion, while you can recycle both, it’s easier to see how to reuse TPR over and over. Companies are always trying to make both materials easier to recycle, but the way PVC is made creates some lasting problems.

Cost is always a big part of any decision in engineering. Usually, PVC is cheaper than TPR. The stuff to make PVC costs less, and they make a lot of it, which helps make it cheaper. Being cheap is a big reason it’s used so much in businesses like building.

TPR is usually more expensive than PVC. Making the basic stuff for it is harder, and it’s seen as a better-quality material. But paying more for TPR at the start can be worth it because it works better in some cases. For example, for a job that needs to be very bendy and strong, a TPR part might last longer, making it cheaper over time.

In the end, picking between them means you have to balance what you need it to do with how much you can spend. For big jobs where you need to save money and PVC is good enough, it’s often the smart choice. But for jobs where you really need the special qualities of TPR, like its great stretch and soft feel, paying more is worth it.