Lad Istar hjælpe dig med at komme i gang med dit projekt med vores erfaring og knowhow!

Upload dine designfiler og produktionskrav, så vender vi tilbage til dig inden for 30 minutter!

You see snap fits every day. Think about the battery cover on your TV remote. Or the cap on your favorite pen. That “click” you hear is a snap-fit joint at work. This article is for you if you want to learn about the common types of snap fit joints. I will share my experience to help you understand how they work, the various types of snap fits you can use, and how to manufacture them right. Reading this will help you design better products.

A snap-fit joint is a very simple way to connect two parts. I think of it as a built-in clip. One part has a small bump or hook. The other part has a spot made for that bump to go into. When you push them together, one piece bends a little. Then it snaps back into place, making a clicking sound. This is a small deformation that locks the parts. The two pieces now fit together as one component.

You should care because these little snap fits make our lives easier. They are a type of fastener, but you do not need any screws or glue. This makes putting things together fast and cheap. For a company, this is great news. It means they can manufacture products quicker. For you, it means products can be made for less money. A good snap-fit joint is strong and simple. You can connect parts without the need for extra tools or a lot of work. That is why snap-fit joints are a type of connection seen everywhere. This simple snap connection is a big deal in design.

I have found many good things about using snap fit joints in my work. The biggest one is how easy they make assembly. You just snap the parts together. It is much faster than using screws or bolts. This is one of the main advantages of snap connections. It saves time and money during the process to manufacture a product.

Here are some more good things about snap fit joints:

Over the years, I have worked with many different types of snap connections. But most of them fall into a few common types. It is good to know the main groups. This helps you pick the right kind of snap for your project. The two most common snap fits are the cantilever snap and the annular snap. They work in slightly different ways.

I made a simple table to show you the difference between these main types of snap fits. Understanding these various types of snap fits is the first step in making a good snap fit joint. These snap joints are the building blocks for many designs.

| Funktion | Cantilever Snap Fit | Annular Snap Fit |

|---|---|---|

| Form | Looks like a small diving board or a hook on an arm. | It is round, like a ring or a lip on a lid. |

| How it Bends | The arm bends up and down. | The ring stretches open and then closes. |

| Almindelig brug | Battery covers, clips, small doors. | Pen caps, bottle caps, round containers. |

| Bedst til | Flat or square parts. | Round or cylinder-shaped parts. |

These two snap fits are the ones you will see most often. But there are other snap fits for special jobs, too.

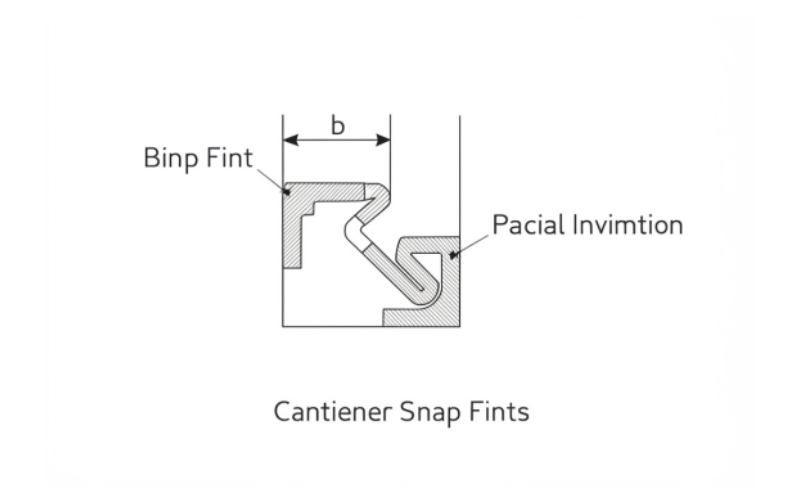

The cantilever snap is my favorite kind of snap-fit. It is simple and it works very well. Imagine a small diving board attached at one end. This is the cantilever. This cantilever arm is the part that does all the work in cantilever joints. When you push two parts together, this arm bends. The bending puts stress on the plastic. A good snap fit design makes sure this stress is not too high. Too much stress can break the cantilever arm. This type of snap fit includes a cantilever.

The design of the cantilever snap fit is very important. The cantilever needs to be long enough to be flexible but strong enough not to break. The most stress happens at the base of the cantilever, where it connects to the main part. We call this point a stress concentration area. Engineers must be careful with the cantilever beam’s shape here to make sure the stress spreads out. When the cantilever hook clears the edge of the mating part, the arm snaps back. It will return to their original shape, and the parts are locked. This widely used snap feature is great because the snap fit can be on just one component. The cantilever snap fits are a classic example of a great snap fit joint. A good snap-fit of this type can last for a long time.

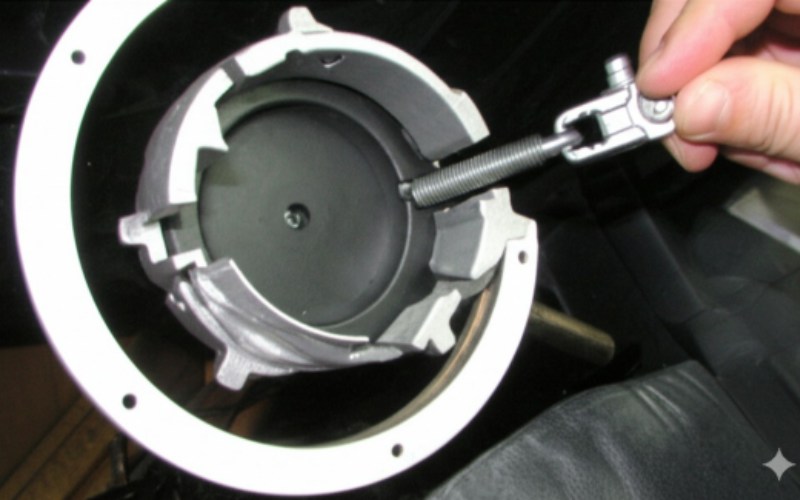

Now, let’s talk about the annular snap. The word “annular” just means “ring-shaped.” And that is exactly what these snap fits are. Think of the lid on a food container or a simple pen cap. That is an annular snap fit. It is used to join two components that are round. The annular snap works by stretching. When you push a pen cap on, the open end of the cap expands just a little to go over a bump on the pen. This creates some stress in the plastic.

Once the cap is past the bump, it snaps back to its original size. This creates a tight seal. This type of snap fit joint is perfect when you need to keep things closed all the way around, like with a lid. These annular snap joints are very strong. It takes an even pull to get them apart. The design of an annular snap fit is tricky. You have to get the size just right. If it is too tight, it will be hard to open and close, or the stress might break it. If it is too loose, it will fall off. These snap fits are great for any application that is used for cylindrical components. This is a very useful snap-fit for many products. The annular snap fit joints are a great choice for round mating parts.

Yes, while cantilever and annular are the big two, I have used other types of snap fit joints for special jobs. You might not see them as often, but it is good to know they exist. Sometimes, a project has a specific design need that the common snap fits cannot solve. That is when you look at these other various types. A good designer knows about all the different snap joints.

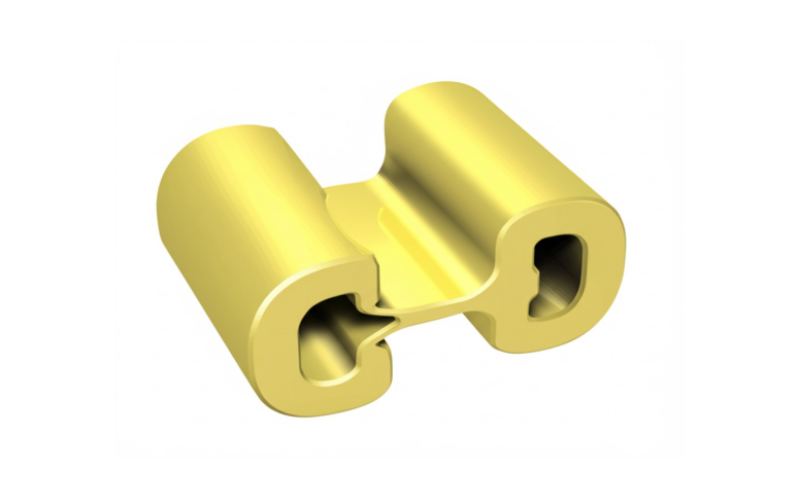

One type is the torsional snap fit. Instead of bending, this snap-fit works by twisting. Imagine a lever that you twist until it snaps into a slot. This creates a strong lock. I have seen a torsional snap fit used in things like car parts where a twisting motion is natural. Another type is the u-shaped snap joint. It works like a cantilever snap, but the arm is U-shaped. This shape helps spread the stress out, making the snap fit joint stronger. Knowing about these other snap fits gives you more options for your product design. It is all about picking the right snap for the job.

The way you manufacture a part has a big effect on the snap fits. Most snap fits are made from plastic. The best way to make lots of plastic parts is with injection molding. I have worked on hundreds of projects that use injection molding. This process is great because you can create the snap feature as part of the main part, all in one shot. There is no extra work to add the snap later. This is a big reason why snap fits are so cheap to manufacture.

To do this, you need a special tool called a mold. The mold is a hollow block of metal that has the shape of your part inside. Hot liquid plastic is forced into the mold. When the plastic cools, it becomes solid. You open the mold and your part comes out, snap features and all. The design of the mold is very important for a good snap. Other ways to manufacture snap features are 3D printing and CNC-bearbejdning. 3D printing is great for making one or two parts to test a design. CNC machining can be used too, but injection molding is the king when you need to make thousands of the same part. The manufacture method you choose will affect your snap fit design.

I have learned that designing durable snap fits is an art and a science. A bad snap fit design will break easily. A good one will last for years. Here are some of the best practices I follow to make a durable snap-fit. First, avoid sharp corners. Sharp inside corners are very bad for snap fits. They create a point of high stress concentration. This is where a snap is most likely to break. Always add a small curve, called a fillet, to the base of the cantilever. This spreads the stress out and makes the cantilever much stronger.

Another key to durability is choosing the right plastic materials. Some plastics, like Nylon, are flexible and tough. They can handle the stress of bending over and over. Other plastics are brittle and will break. You must think about how the snap-fit will be used. Will it be opened once, or a thousand times? The choice of material is a huge part of good snap fit design. Also, you have to think about the shape. A good cantilever arm gets thinner towards the tip. This helps it bend evenly along its length. Following these best practices for designing snap parts will ensure the design is strong. Creating these joints requires careful consideration of stress. The performance of snap connections depends on it.

Even with careful planning, things can go wrong. I want to share some common issues I have seen with snap fit design. The most common problem is that the snap breaks. This usually happens because of too much stress. The part might have a bad design with a high stress concentration, or the material might be too weak. This can lead to fatigue failure if the snap is used many times. The plastic gets tired and cracks.

Another of the common issues is permanent deformation. This is when the snap-fit bends but does not fully return to its original shape. The snap feels loose and does not hold well. This happens if the stress from bending is too high for the plastic. The snap will not fit over time. The loading on the snap-fit is a big factor here. If the part has to hold a heavy load, the snap might slowly bend out of shape. A bad snap fit design can also be too hard to assemble or take apart. Finding the right balance is one of the hardest parts of getting snap fits right. It is one of the most common common issues.

When I start a new project with snap fasteners, I have a checklist of design considerations. These are the questions I ask myself to make sure the snap will work well. First, how many times will this snap-fit be used? If it is for a product that is put together once and never opened, the design requirements are different. But if it is for a battery door, it needs to work for repeated assembly and disassembly. This changes the material I choose and how much stress the snap fit can handle.

Second, what kind of loading will the snap fit joint see? Will it have to hold weight? Will it be pulled or twisted? The direction of the forces on the snap fits is very important for the structural integrity. A snap that is strong in one direction might be weak in another. Finally, I think about the design tolerance. This is how much the size of the parts can vary but still work. The mating part and the snap feature must fit well. Good snap fasteners need careful thought about these details. They are more than just a simple fastener; they are an important part of the product. The types of materials used are also a key part of these design considerations.

I hope this guide has helped you understand the world of snap fits. It is a topic I am very passionate about. They are small features, but they make a big difference. Here are the most important things to take away: