Lassen Sie sich von Istar mit unserer Erfahrung und unserem Know-how beim Start Ihres Projekts unterstützen!

Laden Sie Ihre Designdateien und Produktionsanforderungen hoch und wir melden uns innerhalb von 30 Minuten bei Ihnen!

Have you ever thought about what bridges, cars, and even the fork you use for dinner are made of? A lot of them are made from steel! I believe steel is one of the greatest things ever made. It’s very strong, can be made into almost any shape, and we can recycle it to use it again and again. This article will show you all about the cool world of steel. We will look at what it is, how people make it, and why it’s such a big part of our everyday lives.

I recall the first time I found out about steel. I thought it was just a kind of metal, and it is. But it’s a special kind of metal. Steel is an alloy of iron and carbon. An alloy is what is made when you mix a metal with other things. Picture it like baking a cake. You begin with flour (that’s our iron), and you put in other things like sugar and eggs (that’s our carbon and other elements) to make it perfect. The main parts in steel are iron and carbon. Adding this one thing makes iron much stronger. People have used iron for thousands of years, but when they learned how to add carbon, steel was born and it changed the world.

The amount of carbon, or its carbon content, is very important. It can change what the steel is like. A small bit of carbon makes a different type of steel than a large amount of carbon. Most steel has a tiny bit of carbon, often less than 2%. This tiny amount is what gives steel its great strength and other helpful features. So, when you look at a huge tall building, you can be thankful for the special mix of iron and carbon that is making sure it stays up.

Making steel is a very hot job! It begins with iron ore, which is a type of rock with a lot of iron inside it. First, I found out that workers place the iron ore into a giant oven known as a blast furnace. It gets super hot inside, more than 1,500 °C! The heat is used to smelt the iron, which means it melts the iron so it comes out of the rock. This melted iron is known as pig iron.

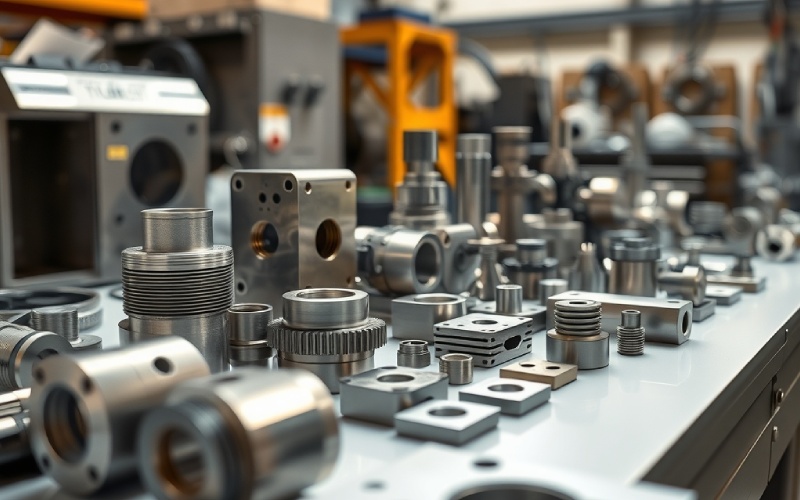

But the pig iron is not steel at this point. It has too much carbon and other unwanted stuff, called impurity elements. To make it into steel, the pig iron is moved to a different furnace, which is sometimes an electric arc furnace. In here, they get rid of the extra carbon and impurities. It’s similar to cleaning the iron. They can also put in other things, called alloying elements, at this point to make different kinds of steel. It’s like an exact recipe. Once the mix is just right, the liquid steel is poured out and cooled into many shapes, like beams and steel rods.

When you listen to people talk about steel, they are usually talking about carbon steel. I think it’s cool that carbon steel is one of the most used kinds. Like the name says, its main alloy part is carbon. There are different kinds of carbon steel, and they are sorted by their carbon content. The level of carbon decides how the steel will be, such as how hard or bendy it is.

Let’s check out the main kinds. First, there is mild steel, which is a kind of low-carbon steel. It does not have much carbon. This allows it to be bent and weld easily. Because it doesn’t cost a lot, you can find it all over the place! Next, we have medium-carbon steel. It’s a little stronger than mild steel. It is used for items like car parts. Last, there is high-carbon steel. This kind has the largest amount of carbon, which makes it very hard and strong. But, this extra hardness can also make it more brittle, which means it might break instead of bend. High carbon steel is wonderful for making tools because it stays sharp. It is a type of plain carbon steel.

| Type of Carbon Steel | Kohlenstoffgehalt | Verwendungszweck |

|---|---|---|

| Mild Steel (Low-Carbon) | Less than 0.3% | Building beams, car bodies, pipes |

| Mittelkohlenstoffhaltiger Stahl | 0.3% to 0.6% | Gears, axles, train tracks |

| Hochkohlenstoffhaltiger Stahl | More than 0.6% | Drills, knives, springs |

Now, this is where it gets very cool for me. At times, we need steel to do even cooler things. We may need it to stop rust or be very, very strong. That’s the time we make alloy steel. An alloy steel is created by putting other elements into the carbon steel mix. These alloying elements give the steel special powers!

Think of it as giving superpowers to our hero, steel, which is already strong. Some things often added are manganese, nickel, chromium, molybdenum, and tungsten. For instance, adding chromium can make stainless steel, which is great at stopping rust. Putting in manganese can make the steel harder and more able to handle a lot of use. Nickel is another element that can make it tougher and help stop corrosion. Scientists can make thousands of different steel alloys for certain jobs. From aerospace parts to tools for doctors, there’s a special alloy for the job. This variety of steel makes it very useful.

I am sure you have stainless steel in your kitchen. Your spoons, forks, and maybe your kitchen sink are probably made from it. Stainless steel is a great kind of alloy that is known for being great at not rusting. This means it doesn’t get rusty without a lot of effort. You can put a stainless steel fork in water, and it will remain shiny. A normal piece of carbon steel would begin to get rusty and change to a brown color.

What’s the secret part? It’s an alloying element known as chromium. To be called stainless steel, the steel needs to have a minimum of 10.5% chromium in its composition. The chromium makes a very thin, clear cover on the top of the steel. If this cover is scratched, it fixes itself right away if there is oxygen nearby! At times, creators add nickel to make it even stronger at fighting corrosion from acids and other tough stuff. This is the reason stainless steel is great for items that are in water a lot or have to be kept very clean.

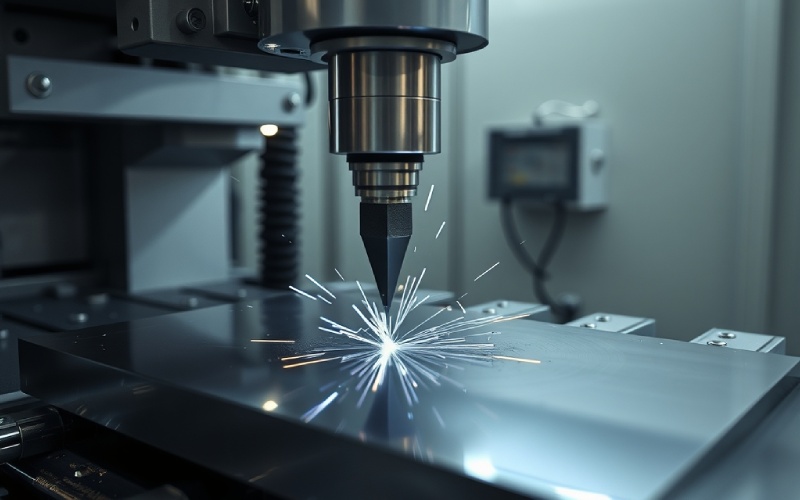

Picture yourself trying to build a house with no hammer or saw. That would not be possible! The tools we have for cutting, shaping, and building need to be created from something very, very tough. This is the job for tool steel. As you can probably tell from its name, tool steel is for making tools. It’s a special kind of alloy steel made to be very hard, strong, and able to stand up to heat and lots of use.

There are many kinds of tool steel. The exact type of tool steel is based on what it is going to be used for. To make them this tough, they are often heat treated. This means heating the metal to a very high temperature and then cooling it off fast. This action can create a very hard form in the steel known as martensite. Different elements like tungsten and molybdenum are put in to make the tool steel right for different jobs. For instance, some tools have to stay sharp even if they become very hot from cutting another metal. The special alloy in the tool steel gives it this great ability to handle heat.

Yes, you definitely can weld steel! Welding is the way of putting together two pieces of metal by melting them on the edges and allowing them to cool to make one single piece. It is similar to gluing them, but using heat. Because steel is so strong, being able to weld it is very important. It lets us build big, tricky things like ships, buildings, and bridges out of smaller pieces of steel.

But, not all steel is simple to weld. Mild steel is famous for being very easy to weld, or weldable. This is one more reason it’s used a lot for building. As the carbon content increases in high-carbon steel, it can be harder to weld. The heat from the welding can make the part around the weld become brittle. At times, welders have to preheat the metal before they weld it to stop this from happening. The ability to weld an alloy is a very important part of why it’s useful for a large project.

One of the neatest things I’ve found out about steel is that you can change its mechanical properties. It’s not the same for every job. You can make it harder, softer, or tougher based on what you need. This is usually done with heat. The way of using heat to change a metal is known as heat treatment.

One common way is to anneal the steel. When you anneal steel, you warm it up and then allow it to cool off very slowly. This action makes the steel softer and more ductile. A ductile material is something that can be pulled into a wire form and not break. This is called ductility. But if you want to make steel harder, you can heat it to a high temperature and then cool it off very fast, a method called quenching. This makes it harder and increases its tensile strength, but it can also make it more likely to be brittle. So, engineers need to find just the right mix to make steel that works perfectly for a job, including specific design features and geometric tolerances.

I used to think about why my bike would get spots of rust if I left it in the rain. The answer is corrosion. Corrosion is something that happens in nature where a clean metal tries to change back to what it was at first, like iron ore. For steel, this action is known as rusting. Most kinds of carbon steel and low-alloy steel are not great at stopping rust. When iron touches oxygen and water, something chemical happens that makes iron oxide, which we know as reddish-brown rust.

This is a large problem since rust can make the steel weaker and in the end make it break. To keep it safe from the weather, steel is often covered with something to shield it. Paint is an easy and popular cover. Another way is galvanizing, where the steel gets a layer of zinc in a method called hot-dip galvanizing. The zinc keeps the steel safe from corrosion. This is why items such as streetlights and guardrails often have a silvery, metallic appearance. The one that’s different, of course, is our shiny friend, stainless steel, which has its own way to stop rust!

Yes, and this is the best part! Steel is one of the most reused materials on Earth. I believe that’s great news for our world. Nearly all of the steel used around the world can be melted down and used again, and it will be just as good. This means we can recycle old cars, kitchen machines, and food cans to create new steel items.

When we recycle steel, we save a lot of power. It uses a lot less power to recycle steel than to create new steel from iron ore. We also save things from nature and make less pollution from digging in mines and from the blast furnace. The steel is gathered, sorted, and then brought to a mill where it’s placed in a furnace, usually an electric arc furnace, to be melted down and turned into new steel. The ability to recycle this metal so simply is one of the biggest good things about using steel as a manufacturing material. It’s a wonderful way to help our planet.