Lassen Sie sich von Istar mit unserer Erfahrung und unserem Know-how beim Start Ihres Projekts unterstützen!

Laden Sie Ihre Designdateien und Produktionsanforderungen hoch und wir melden uns innerhalb von 30 Minuten bei Ihnen!

“Tapped hole” and “threaded hole” are 2 terms that often get blended. Initially look, they seem to be the exact same point. Nevertheless, both let you screw in a bolt or various other fastener. Yet there’s a little, essential distinction in just how they are made that can matter for your project. Comprehending this distinction is vital to ensuring your mechanical settings up are solid and trusted. In this short article, I’m going to break down the tapped hole vs. threaded hole comparison in basic terms. I’ll share what I’ve discovered throughout the years to aid you recognize specifically what you’re working with and why it matters.

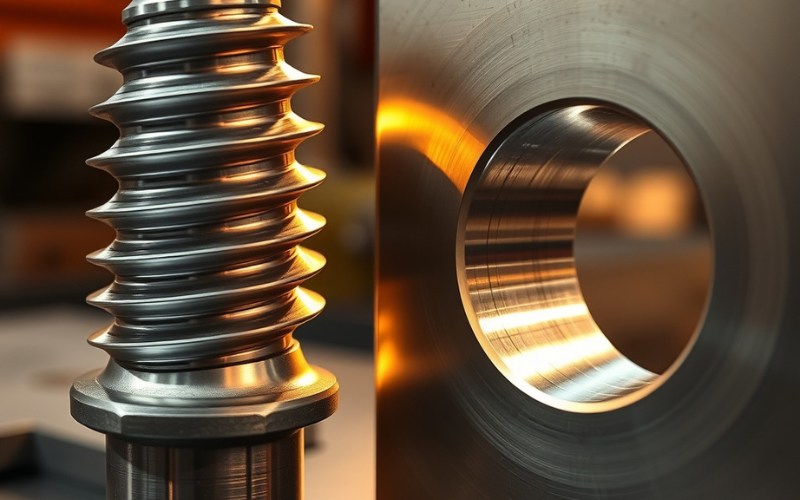

Allow’s begin with the basics. In the easiest terms, a threaded hole is any opening that has internal threads reduced into its surface. Think of it as the partner to a bolt or a screw. You have a threaded fastener — like a bolt — with an external thread , and it requires an area to go. That location is the threaded hole . The helical grooves, which are the essence of a thread , inside the hole match the thread on the fastener . This permits you to screw them together, creating a strong link that holds parts in place. The main work of a threaded hole is to give a safe and secure point for a fastener , allowing for setting up and disassembly.

Anytime you see a hole made to accept a screw or bolt , you’re taking a look at some kind of threaded hole. The term threaded hole is a basic group. It matters not how the thread arrived; if it has a spiral groove to approve a fastener , it’s a threaded hole . This can be in steel, plastic, or timber. The thread inside the hole is a simple equipment, a ramp twisted around a cylinder, that gives a screw its holding power. The top quality of this thread is extremely vital for the stamina of the last assembly. A poorly made thread can remove, meaning the fastener won’t hold. The procedure of creating this inner thread can be carried out in a number of ways. The threaded hole is the outcome of a threading process .

Currently, here’s where the distinction can be found in. A tapped hole is a certain Typ of threaded hole . The keyword here is “touched.” This implies the internal thread was created utilizing a tap . A tap is an unique cutting device made to reduce a thread on the inside of a hole. So, while every tapped hole is a threaded hole , not every threaded hole is a tapped hole . Think of it similar to this: all squares are rectangular shapes, yet not all rectangular shapes are squares. A tapped hole is just a threaded hole made with a particular device.

The term “tapped” tells you wie the thread was made. This is important since the method utilized to create strings can impact the stamina and accuracy of the thread itself. When somebody specifies a tapped hole , they are referring to the standard procedure of creating an internal thread with a tap . This procedure is really typical in whatever from a little home job to large manufacturing. The tap is a specific tool that guarantees the thread size and pitch are proper, allowing for a conventional fastener to fit flawlessly. So, the term threaded hole is broad, however tapped hole is specific.

Yes, there is a refined however essential difference in between the terms tapping and threading . As I mentioned, tapping is the particular act of reducing an internal thread using a tap . It is just one of lots of techniques that fall under the wider umbrella of threading . You can think about the tapping process as a specialized skill within the larger craft of making strings. The device, the tap , is created just for this function: to develop internal threads . It’s a very direct and effective way to finish the job.

Threading , on the other hand, is a general term for the process of developing any type of thread . This consists of producing the interior thread in a threaded hole , however it likewise describes creating the external thread on a bolt or screw . Moreover, there are various other means to produce internal threads besides using a tap . For instance, in high-volume production, a thread mill might be made use of on a CNC equipment . Or, for sure applications, a forming tap may be made use of to push the thread right into the product rather than sufficing. All of these methods become part of the larger threading procedure . So, tapping is a kind of threading , but threading incorporates much more than simply tapping .

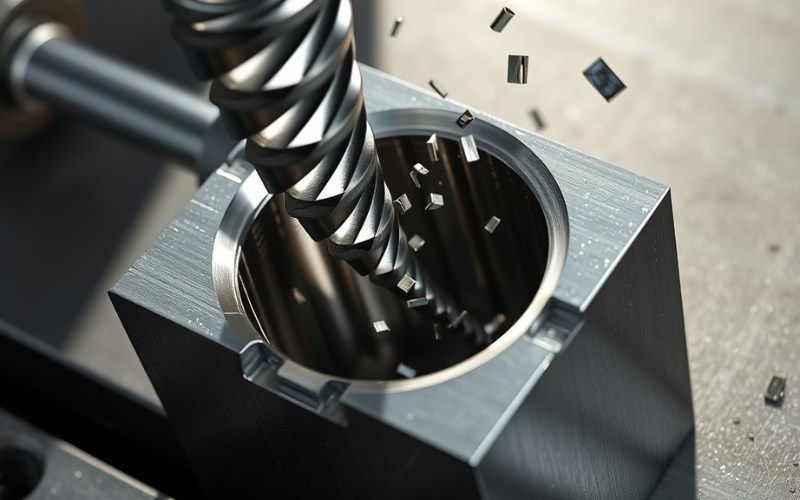

Producing a tapped hole is a simple procedure, but it needs care. The initial step is always to drill an opening. This is called the pilot opening or pierced hole . The dimension of the opening you drill is very crucial. It must be slightly smaller sized than the final thread diameter to leave enough product for the tap to cut right into. There are common charts that inform you exactly which dimension pierce bits to make use of for each thread size . Making use of the incorrect dimension opening will certainly cause a weak or nonexistent thread .

As soon as the opening is drilled, the tapping process begins. You take the tap , which looks a bit like a screw with sharp sides, and location it into the opening. The tap is after that turned, either by hand with an unique wrench or by a machine . As the tap turns, its reducing edges shave away material to develop the strings inside the opening. It’s critical to keep the tap right and to utilize cutting fluid to lube the process and remove the metal chips. This avoids the tap from damaging, which can be a genuine migraine to take care of. This is the classic means to produce threads and is a fundamental skill for any type of machinist . The tap is the important reducing device for this job.

While tapping is really typical, it’s not the only means to make a threaded hole . Modern manufacturing, especially with CNC machining , often uses a strategy called thread milling. In this threading process , a specialized rotating tool called a thread mill is utilized. Rather than the tool being the same size as the thread , the thread mill is smaller and relocates a spiral path inside the opening to cut the thread . A CNC device regulates the activity with unbelievable precision. This technique is very adaptable due to the fact that a single tool can be configured to produce strings of various dimensions and types, consisting of both left-hand and right-hand strings.

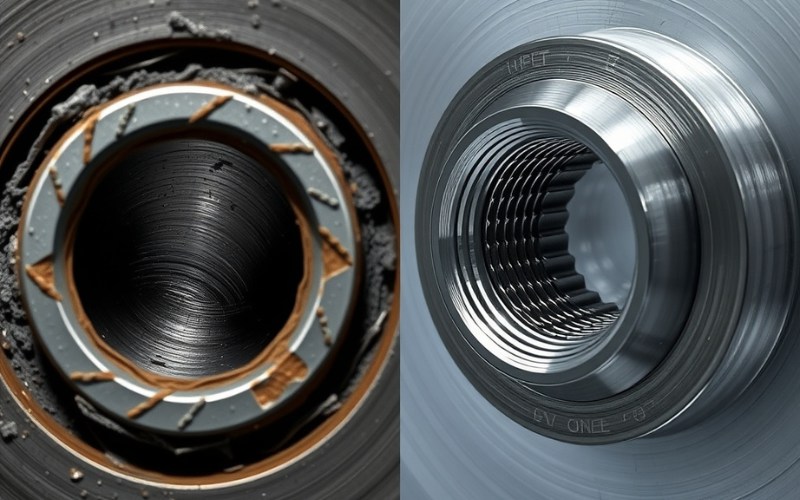

Another important approach is thread creating . As opposed to removing product, thread creating utilizes a special kind of tap , called a forming tap , to displace the product. The forming tap essentially pushes the metal right into the form of a thread . This procedure develops an extremely strong thread due to the fact that it work-hardens the product. It’s frequently utilized in softer metals like light weight aluminum. For circumstances where a really strong thread is required in a weak product, threaded inserts can likewise be utilized. These are metal coils or bushings that are inserted into a larger opening to offer a resilient threaded hole . Each threading process has its place in a range of producing setups.

The decision between producing a tapped hole versus a threaded hole made by one more technique often comes down to the particular application. The timeless tapped hole vs milled opening debate is common in factory. Using a tap is commonly quicker for standard-sized openings in materials that are very easy to machine. For one-off jobs, repair services, or low-volume production, hand-operated tapping is a cost-efficient and trusted means to develop threads . An easy tap and wrench are all you require.

However, for more complex or demanding work, various other threading process methods might be better. Thread milling on a CNC equipment provides even more control over the thread fit and can be used on tough materials where a tap might risk damage . Due to the fact that the thread mill is not the very same diameter as the thread , there is much less tool get in touch with, which can be an advantage. The touched openings vs threaded holes option likewise depends on the kind of opening . For a blind hole , where the hole doesn’t go all the way via, chip removal can be a problem for a cutting tap , making a thread mill or forming tap a much better choice. The details requirements of the part’s geometric design will certainly direct the very best choice.

If you choose to create a tapped hole , you’ll locate that there isn’t just one type of tap . One of the most typical kinds you’ll run into are the taper tap , plug tap , and bottoming tap . Each one has a different amount of taper , or chamfer, at the tip.

You typically use these taps in sequence. You start with the taper tap to get the thread started directly, adhere to up with the plug tap to obtain most of the thread depth, and ultimately make use of the bottoming tap if you need the thread to copulate to the base of a blind hole . Each cutting tap contributes in the tapping process .

Yes, you can definitely tap a blind hole . A blind hole is an opening that is pierced to a details depth and does not pass right through the product. Tapping a blind hole is a common task, but it presents an unique difficulty: chip evacuation. When you cut threads with a reducing tap , you develop little chips of steel. In a through opening, these chips can just fall out the other side. In a blind hole , they have nowhere to go and can develop, possibly obstructing and breaking the tap .

To effectively tap a blind hole , you need to utilize the best method and the right devices. It’s vital to regularly back the tap bent on damage the chips and clear them from the opening. Utilizing an unique kind of tap called a spiral flute tap can additionally help, as it is made to draw the chips up and out of the blind hole . As mentioned before, this is where a bottoming tap is essential. After starting the thread with a taper tap and strengthening it with a plug tap , the bottoming tap allows you to reduce a usable thread as close to the bottom of the blind hole as possible. Mindful interest to hole depth is vital when tapping a blind hole .

In contemporary production, CNC machining has revolutionized tapping and threading processes . A CNC (Computer System Numerical Control) equipment can perform these procedures with a level of precision and repeatability that is tough to achieve by hand. For tapping , the equipment can control the rotation and feed of the tap flawlessly, which greatly minimizes the threat of tap damage and guarantees a regular, high-quality thread in every threaded hole .

CNC machining is specifically vital for thread milling. This process would be nearly difficult to do by hand. The CNC maker is configured utilizing CAD (Computer-Aided Layout) software application to lead the thread mill in its specific helical course. This enables the creation of extremely precise and complicated threads in a range of materials , including difficult products . A machinist can utilize a single thread mill to produce a range of thread sizes, which is extremely reliable. For any type of kind of high-volume production of parts with touched and threaded openings , CNC machining is the only means to go. It is a cornerstone of range of making for mechanical settings up .

When it boils down to it, the tapped hole vs threaded hole conversation is about recognizing the terms. The most crucial thing to remember is that a tapped hole is merely a kind of threaded hole . Both are designed to accept a threaded fastener like a screw or bolt . The crucial distinction hinges on the method made use of to produce the thread . A tapped hole is constantly made utilizing a tap . A threaded hole could be made using a tap , a thread mill , a forming tap , or even with spreading.

The resemblances and differences are important for communication. If you tell a machinist you need a threaded hole , they may ask for more information regarding exactly how it must be made. If you claim you require a tapped hole , they understand precisely what device and process to utilize. To make it also clearer, right here is a simple table laying out the touched openings vs threaded holes comparison:

| Attribute | Gewindebohrung | Various Other Threaded Holes (e.g., Grated) |

|---|---|---|

| Outcome | An interior thread for a fastener . | An internal thread for a fastener . |

| Merkmal | Accepts a screw or bolt . | Approves a screw or bolt . |

| Refine | Always created making use of a tap . | Usually produced with a thread mill or forming tap . |

| Devices | Drill and Tap ( taper tap , plug tap , bottoming tap ). | Drill , Thread Mill , specialized device tools. |

| Anwendungsfall | General purpose, repair work, low-volume manufacturing. | High-volume CNC machining , complex components, difficult materials . |

Recognizing this distinction assists you make far better decisions for your projects and interact your needs plainly.