Lassen Sie sich von Istar mit unserer Erfahrung und unserem Know-how beim Start Ihres Projekts unterstützen!

Laden Sie Ihre Designdateien und Produktionsanforderungen hoch und wir melden uns innerhalb von 30 Minuten bei Ihnen!

I have worked with words for a long time, but I started out by studying chemical engineering. That early learning gave me a real respect for the materials that make up our world. One of the most basic ideas I learned was yield strength. You hear this term a lot in building and making things. But what does it really mean for a piece of metal? In this article, I want to explain yield strength in a simple way. You won’t need a special degree to understand it. We will look at why it is a very important quality for any metal object. This is true for everything from a paperclip to the frame of a tall building. Knowing about this idea helps make sure the things we build are safe and will last a long time.

Picture a metal spring in your mind. You can pull it, and it gets longer. When you let go, it goes right back to its first shape. We call this elastic change. The metal is acting like a rubber band. You can put a certain amount of stress on it. It will return to its original shape. It does this without undergoing permanent deformation.

But what happens if you pull on it too much? At some point, the spring will not go back to how it was. It will be stretched out for good. This is where yield strength is important. The yield strength is the stress where a metal changes from an elastic change to a plastic deformation. It’s the point where the material begins to deform plastically. You can think of it as a point of no return for the metal. Once you go past the yield point, the change is forever. This quality is often shown as σy.

The yield strength is a very important number for engineers. It shows them the biggest amount of stress a metal can withstand before it starts to change shape forever. This is super important for designing things like bridges, buildings, cars, and planes. You need to be sure that the materials you use can handle the stress of daily use. They should not bend or break for good. The unit for yield strength is usually megapascals (MPa) or pounds per square inch.

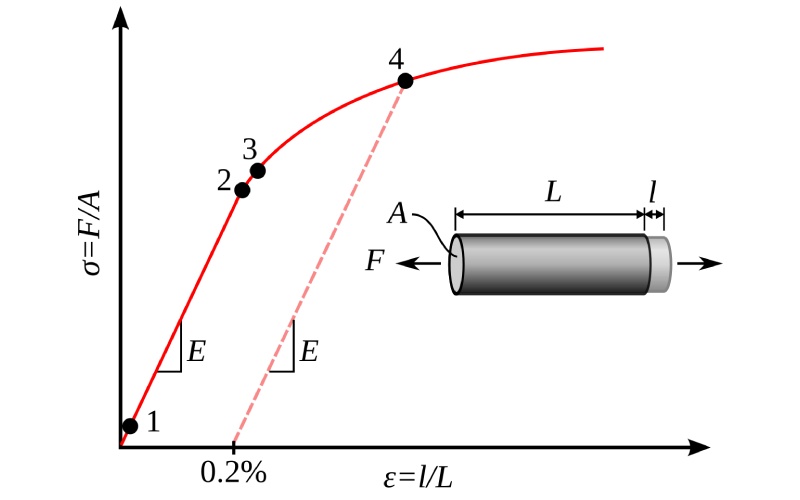

To discover the yield strength of a metal, engineers use a special machine. This machine pulls on a small piece of the metal until it snaps. This is known as a tensile test. While the test is happening, the machine records the amount of force, or stress, it is using. It also records how much the metal stretches, which is called strain.

The numbers from this test are then put on a graph. This graph is called a stress-strain curve. The graph shows how the stress and strain relate to each other for that metal. The stress-strain curve is a very helpful tool. It tells us many important things about a metal, like its yield strength.

For some kinds of metal, like mild steel, you can see a very clear yield point on the stress-strain curve. You can spot a clear point where the metal begins to deform even though the stress does not go up. For other metals, such as aluminum, the change from elastic to plastic is slower. In these situations, engineers use a special way to find the yield strength. It is called the 0.2% offset method. They find it by drawing a line that is parallel to the linear portion of the stress-strain curve. This line is moved over by 0.2% strain. The place where this new line crosses the stress-strain curve is called the yield strength. This point is also sometimes called proof stress.

It is easy to mix up yield strength and tensile strength. But they are two very separate things. We already talked about how yield strength is the point where a metal starts to deform permanently. On the other hand, tensile strength is the maximum stress a metal can withstand before it starts to break.

Think about it like this. Yield strength is about bending, but tensile strength is about breaking. Once a metal gets to its yield strength, it has already started to fail because it will not go back to its first shape. But it can still withstand more stress before it breaks completely. The tensile strength is the highest possible stress the metal can take. After that point, it starts to get thinner in one spot, which is called “necking,” and then it breaks. Necking happens when the cross-sectional area of the material starts to get smaller.

For many uses, yield strength is a more important number than tensile strength. This is because once a part has permanently changed shape, it might not work correctly anymore, even if it has not broken. For instance, you would not want the wing of a plane to bend for good, even if it did not snap off. In many materials that can bend easily, the material will start to deform long before it gets to its highest tensile strength.

The yield point is a very important piece of information for anyone who designs or works with metal. It shows the highest load you can safely put on a metal part. If the stress on the metal stays under the yield point, the part will act in an elastic way. It will go back to its first shape when the load is taken off. This is key for the safety and reliability of many structures and machines.

Knowing the yield point is very important to stop things from failing. When a metal has more stress on it than its yield point, it goes into the plastic deformation stage. This permanent change in shape can make something stop working. In some cases, it can lead to a disastrous failure. For example, think about a steel beam in a bridge. If it was loaded with too much weight, past its yield strength, it would sag permanently. This would harm the strength of the whole bridge.

Engineers use the yield strength as a main number in their plans. They usually design parts so that the stress they will face is much lower than the yield strength of the metal. This creates a safety buffer. It makes sure that the part will not permanently deform when it is being used normally. The yield point is a basic idea that helps make sure the things we build are safe and will be around for a long time.

I have talked about the stress-strain curve a few times. Let’s break it down so it’s easy to picture in your mind. Think about pulling on a piece of taffy. At first, it stretches just a little. If you stop pulling, it goes back to its first length. This is the elastic area of the stress-strain curve. On the graph, it looks like a straight, linear line. The connection between stress and strain is proportional, or balanced, here.

Now, think about pulling on the taffy even more. At some point, it starts to stretch and get thin in the middle. Even if you let go, it will not go back to its first shape. This is the start of plastic deformation. This is where the stress-strain curve begins to curve. The spot where this curve starts is the yield point.

If you keep pulling the taffy, it will get thinner and thinner until it finally breaks. This final break is the fracture point on the stress-strain curve. The very highest point on the curve, before it starts to go down, is the tensile strength. The whole graph gives us a full picture of how the metal acts under different kinds of stress. The linear portion of the stress-strain curve is where the material has elasticity. The end of the linear portion is also called the elastic limit.

For certain kinds of metal, especially mild steel, the yield point is not just one spot. Instead, you might see something called an upper yield point and a lower yield point. This is because of the way the atoms are set up in the crystalline structure of the metal.

The upper yield point is the stress at which a material first starts to change shape for good. You will see the stress suddenly go down right after this point on the stress-strain graph. This is because the atoms inside the metal suddenly slide past each other. This is the point where plastic deformation begins. After this first slip, the stress you need to keep it changing drops a little. This new, lower level is the lower yield point.

For engineers, the lower yield point is usually the more important number. This is because it is more steady and you can count on it. After the lower yield point, the metal will keep changing shape with about the same amount of stress for a while. This is also the point where strain hardening begins. This is the time when things called Luders bands show up in the test section. This action is a key part of the different stresses a material experiences as the strain and the test equipment interact.

An alloy is a mix of a metal and other materials. A good example is steel. Steel is an alloy made of iron and carbon. When we add other materials, we can change the qualities of the main metal. This includes its yield strength. This is a very handy concept for engineers.

Adding alloying elements can make the yield strength of a metal higher in a few ways. These added materials can mess up the neat rows of atoms in the crystal structure. This makes it harder for the atoms to slide past one another. Because of this, you need a larger amount of stress to cause plastic deformation.

For instance, adding carbon to iron to create steel makes its yield strength much higher. Different kinds of steel have different amounts of carbon and other alloying elements. This gives them a big range of yield strengths. That is why some steels are good for making car bodies, but other steels are used for strong bolts. The power to adjust the yield strength of a metal by making an alloy is a very important tool in materials science. An alloy can also be used to harden a metal.

The yield strength of various metals can be very different. It depends on the kind of metal, how pure it is, and how it was made. Here is a table that shows the approximate yield strengths for some well-known metals and alloys. Just remember that these are general numbers. The real yield strength can change.

| Metal/Alloy | Approximate Yield Strength (MPa) |

|---|---|

| Annealed Aluminum | 15-20 |

| 6061-T6 Aluminum Alloy | 241 |

| Annealed Copper | 33 |

| Messing | 95-345 |

| Mild Steel (ASTM A36) | 250 |

| Alloy Steel (ASTM A514) | 690 |

| Titan | 450 |

| Wolfram | 550 |

As you can tell, there is a big range of yield strengths. A soft metal like annealed aluminum has a very low yield strength. A very strong alloy steel has a very high yield strength. This is the reason you’ll find that different metals are used for different jobs. The yield strength is a big part of deciding what a metal can be used for. The yield strength of a metal is usually measured in MPa (megapascals). For comparison, human skin has a yield strength of about 15 MPa.

I have talked about this a little already. But I want to give you some clear examples of how yield strength is part of our daily lives. Every time you go over a bridge, ride in a plane, or even use a simple wrench, you are depending on the yield strength of metal.

To put it simply, yield strength is a basic quality that helps keep the world around us safe and lasting. If we did not understand yield strength, we could not build the amazing things we use every single day.