Deje que Istar le ayude a poner en marcha su proyecto con nuestra experiencia y conocimientos.

Cargue sus archivos de diseño y requisitos de producción y nos pondremos en contacto con usted en menos de 30 minutos.

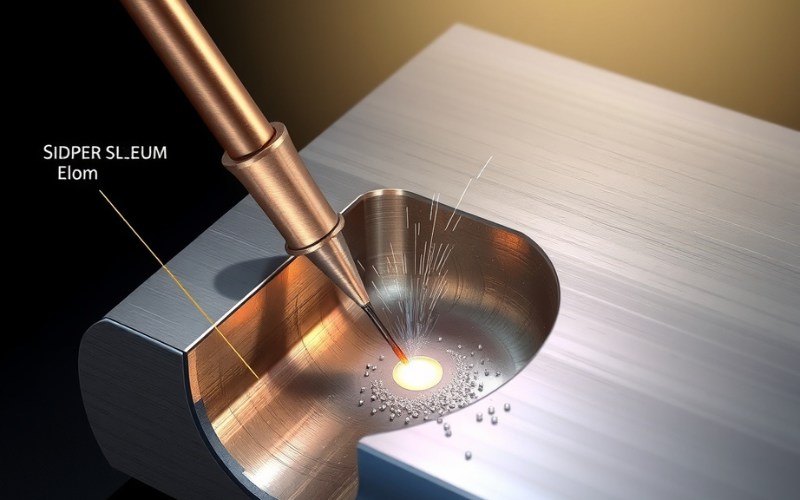

Sinker EDM Machining works like a little bit of magic. It uses sparks to shape metal into parts with amazing detail. In this article, I want to tell you all about this great method. We will look at how it works, what it is used for, and how it compares to other ways of doing things. If you need to make parts with tricky shapes and very high accuracy, this is a tool you should learn about.

Sinker EDM is a special way of shaping metal. It is also called ram EDM or plunge EDM. It uses electric sparks to do the work. Just think of a tiny lightning storm that happens thousands of times every second. This storm carefully shapes a piece of metal. That is the basic idea of how this machine works. It is great for making tricky shapes and holes. These shapes would be hard or even impossible to make with regular tools.

The main idea behind the process is using sparks to wear away metal in a very careful way. This is a type of electrical discharge machining. It uses an electrode, which is a tool with a special shape. This tool is pushed, or “sunk,” into the metal part, which is called the workpiece. Both the electrode and the workpiece are put under a special oil called dielectric fluid. This oil does not let electricity pass through it easily. The sinker EDM machine then creates a strong spark between the electrode and the workpiece. This spark is very, very hot. It gets hot enough to melt and turn a tiny bit of the metal on the workpiece into vapor.

This happens over and over, thousands of times per second. Every spark takes away a very small piece of metal. This makes a tiny hole. As this continues, the electrode slowly sinks deeper into the workpiece. It creates a hole, or cavity, that is a perfect copy of the electrode’s shape. This is a machining method that does not use touch. The tool never actually touches the part. This is a big plus. It means the tool does not push on the part. This stops the part from bending. It also lets you make very fine and detailed parts. The machine has very good control over the small space between the electrode and the workpiece. This makes sure the sparks are steady and accurate. This whole process is a great example of a powerful way to shape metal.

To really get how sinker EDM works, you need to know the machine itself. A sinker EDM machine is a piece of equipment with many important parts that work with each other. You can think of it like a team where every person on the team has a very important job.

Here is a list of the main parts of an EDM machine:

| Pieza | Qué hace |

|---|---|

| Fuente de alimentación | This is the machine’s power source. It makes the electric pulses needed for the sparks. |

| Spindle Head (Ram) | This part holds the electrode. It moves the electrode up and down into the workpiece. |

| Mesa de trabajo | This is the flat surface where the workpiece is held down tight. |

| Dielectric Fluid System | This system has a tank for the dielectric fluid. It also has pumps and filters. It keeps the oil moving and clean. |

| Controlador CNC | This is the computer “brain” of the machine. It tells the ram where to move and controls the electric sparks. |

| Electrode | This is the special tool that makes the shape in the workpiece. We will talk more about this next. |

Every piece of the EDM machine is made to be very accurate. The frame of the machine is very strong and stiff so it does not move. The parts that move the ram have very fine control over the small space between the tool and the part. All these parts work together so the sinker EDM machine can make machined parts with great accuracy.

The electrode is a very important part of the sinker EDM process. You can think of it as a painter’s brush. The shape of the electrode decides the final shape of the hole in the workpiece. If you want a square hole, you must use an electrode that is square. If you need a difficult shape that is not regular, you need to make a custom electrode with that same shape. The sinker EDM machine basically makes a copy of the electrode’s shape in the metal.

Electrodes are usually made of materials that are good at carrying electricity. They also need to handle the very high heat from the spark. The two materials used most often are graphite and copper. Graphite is very common. It is easy to shape into difficult forms, it lasts a long time, and it does not cost too much. Copper is another good choice. It is great when you need a very smooth surface finish. For very hard jobs, other materials like tungsten or a mix of copper and tungsten are used. The material you pick for the electrode depends on the workpiece material, how smooth you want the surface to be, and how fast you need to remove the metal. The electrode itself slowly wears away during the process, so you have to plan for that in the manufacturing process.

I must say this again: the dielectric fluid is extremely important for sinker EDM. It does more than just sit there. It has many important jobs. The most common dielectric fluid used for sinker EDM is a type of oil.

Here is what the dielectric fluid does:

A sinker EDM machine could not work without the dielectric fluid. The fluid has to be kept clean and at the correct temperature to get the best results. This is why every EDM machine has a good system for filtering and cooling its dielectric fluid.

Over my career, I have used EDM services for many different kinds of jobs. This technology that uses sparks to remove metal can be used in many ways. It is very good for making parts that are too difficult or made of materials that are too hard for normal machining.

One of the biggest sinker EDM uses is for making a mold or a die. Look at the plastic things you see every day, like your computer mouse or a toy brick. A lot of those things are made with a process called injection molding. Sinker EDM is the best way to make the detailed steel mold used for that. The process is great for making the complex holes and fine detail needed for a good injection mold. It is also used to make the dies used for stamping metal sheets.

Here are some things it is often used for:

Because the sinker EDM machine does not use force to cut, it can work on very hard materials without a problem. This makes it a great choice for working with tool steel, tungsten carbide, and other strong alloys.

When people discuss EDM machining, they usually talk about two main kinds: sinker EDM and wire EDM. I have used both of them a lot. They are both great tools, but they are used for different kinds of jobs. The biggest difference between sinker EDM vs wire EDM is the kind of electrode they use.

In sinker EDM, the electrode is a solid tool that is made into a special shape. It pushes into the workpiece to make a 3D hole. You can think of it like a stamp that burns its shape into the metal. This way is perfect for making blind holes, molds, and other complex shapes.

Wire EDM is different. It uses a very thin wire that is always moving to act as the electrode. This wire, which is usually made of brass, works like a very exact saw. It cuts a path through the workpiece. Wire EDM is great for making very accurate 2D cuts and shapes that go all the way through a part, even if the part is very thick. It is like using a power saw, but it uses a spark instead of a blade. Using a wire as an electrode allows for amazing detail and very tight accuracy.

Here is an easy way to compare them:

| Característica | Electroerosión por penetración | Electroerosión por hilo |

|---|---|---|

| Electrode | A solid tool with a special shape | A thin, moving wire |

| Type of Cut | Makes 3D holes and blind shapes | Makes 2D cuts and shapes through a part |

| Lo mejor para | Molds, dies, difficult holes | Exact cuts, detailed shapes, punches |

| Fluido dieléctrico | Usually oil | Usually special clean water |

Both are wonderful technologies. You just need to choose the one that is right for the shape of the part you need to make. For some very hard manufacturing jobs, we might even use both methods on the same part!

I have worked with both sinker EDM and CNC machining for a long time. I can tell you that both are very important, but they are used for different things. CNC machining, which includes tools like a CNC mill, is a process that cuts metal away. It uses spinning tools like a drill or a mill to remove the metal. It is usually faster and cheaper for easy shapes and softer metals.

But sinker EDM is better in some key areas where CNC machining cannot do the job. The biggest plus is that it can work with very hard materials. After a piece of steel is made hard, it is very difficult to cut with a normal tool. A sinker EDM machine does not care how hard the material is. As long as the material can carry electricity, the machine can shape it. This is why sinker EDM is the best process for making tools and molds from hardened steel.

Another big plus is that it can make complex and detailed shapes that a spinning mill tool cannot make. Sinker EDM can make sharp inside corners, deep and thin walls, and other small details very accurately. Because there is no tool touching the part, there is no pressure. This means you can work on very thin or delicate parts without worrying about breaking them. CNC milling can be faster for removing a lot of material quickly. But for the small, difficult details in hard metals, sinker EDM is the best choice. The material removal rate is not as fast, but the level of detail is much better.

There is one main rule for sinker EDM. The workpiece must be made of electrically conductive materials. If electricity cannot go through it, you cannot make a spark. This means the process will not work. So, you cannot use sinker EDM on materials like plastic or ceramic.

But for metals, sinker EDM is wonderful. It works on many types of metal, especially hard materials that are tough to shape with other tools. The hardness of the metal does not change how well this process works.

Here are some of the materials that are a good fit for sinker electrical discharge machining:

The fact that it can work with these tough and conductive materials is what makes the sinker EDM machine such a useful tool for making things today.

Just like any way of making things, sinker EDM has its good points and its bad points. I have learned that knowing these helps me choose if it is the right tool for a certain job.

Good Things (Benefits):

Bad Things (Limitations):

Knowing these points is very important. For a simple part made of a soft metal, CNC milling is likely a better choice. But for a difficult mold hole in hard tool steel, sinker EDM is the perfect answer.

If you do not have a sinker EDM machine at your own shop, you will need to find a company that offers EDM services. Finding a good partner is very important to get high-quality machined parts. I have worked with many companies that offer EDM machining services, and I know what to look for.

First, check their experience. How long have they been offering sinker EDM services? Do they have experience with the same materials and types of parts that you need? Ask to see some of the work they have done before. A shop with a lot of experience will know all the little details of the sinker EDM process. They will know how to design the right electrode and pick the best settings for the machine.

Next, look at their machines. A good EDM service will have new and well-cared-for sinker EDM machines. Newer machines usually have better computer controls. This leads to more accurate parts and a better surface finish. They should also be able to make the electrodes themselves. Finally, good talking is very important. A good manufacturing partner will work with you to understand what you need. They will give you ideas and let you know how your project is going. Picking the right EDM services can make a huge difference for your manufacturing needs.

To finish up, here are the most important things you should remember about sinker EDM machining: