Deje que Istar le ayude a poner en marcha su proyecto con nuestra experiencia y conocimientos.

Cargue sus archivos de diseño y requisitos de producción y nos pondremos en contacto con usted en menos de 30 minutos.

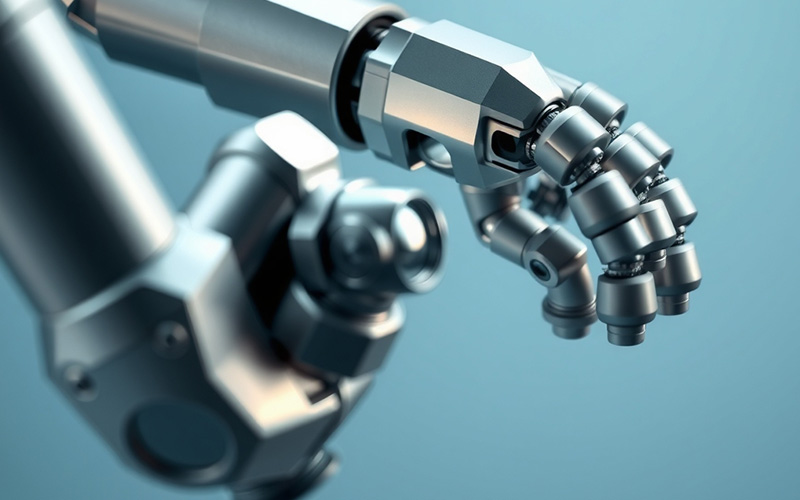

The robotics these days are more than just equipments; they are complex systems that are coming to be a larger component of our lives. When you consider a robot, you could see a futuristic maker, yet I see the fantastic products that make it all possible. The option of materials for robot construction is a key part of what makesA a robot job well. This write-up will discover the different products used in robotics, from the strong steels that create their structure to the smart materials that provide brand-new capacities. We will certainly look at why selecting the best product is so vital for the advancing robotics landscape.

When I think of the classic industrial robots I’ve seen on , the very first point that comes to mind is their strength and durability. These workhorse machines are typically made from metals and alloys that can manage tough jobs. Steel is a preferred choice since it is very solid and not too expensive. This makes it great for the major structure of a robot that needs to raise heavy things over and over again. You’ll discover steel in the equipments and electric motor components of lots of robotic systems also.

One more common steel is aluminum. It’s much lighter than steel, which is a big benefit for a robot that needs to move rapidly. Consider a robotic arm on a production line that has to move with speed and precision. Lighter products suggest the robot can relocate faster and make use of much less energy. Aluminum is additionally very easy to machine, which suggests it can be shaped right into personalized components like rooms and wheels.

For jobs that need even more strength without the weight, titanium is the top choice. It has an extremely high strength-to-weight ratio and is really immune to corrosion. This makes it best for aerospace robotics or clinical robotics where efficiency and integrity are essential. While titanium is more pricey, its unique properties make it worth the expense for certain state-of-the-art robot applications.

Here’s a peek at just how these steels contrast:.

| Product | Key Feature | Usual Robotic Applications |

|---|---|---|

| Acero | High strength, durability, affordable | Structures, gears, motor components |

| Aluminio | Lightweight, excellent strength-to-weight ratio, easy to maker | Structures, robot arms, rooms, wheels, bearings |

| Titanio | Extremely high strength-to-weight proportion, corrosion resistance, biocompatible | Aerospace robotics, medical robots, humanoid robot joints |

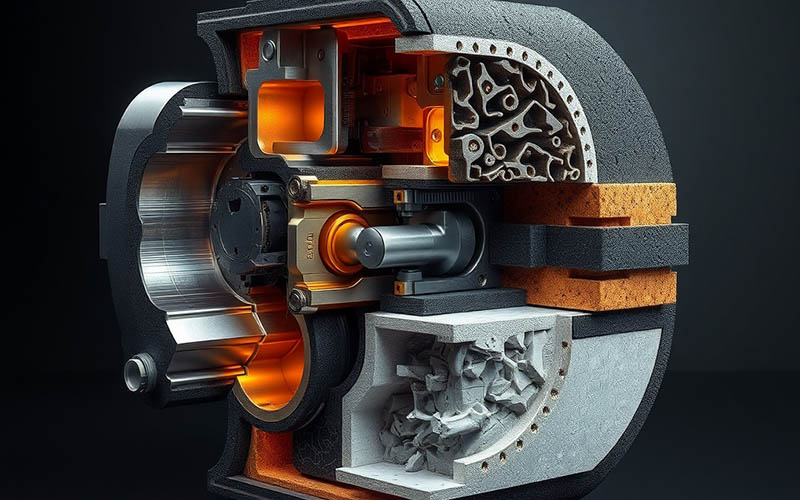

I’ve constantly been fascinated by how we can incorporate products to develop something even better. That’s the idea behind composite materials. These are made by mixing 2 or even more various materials to get the best top qualities of each. Worldwide of robotics, composite materials are a game-changer. They offer a way to make a robot that is both strong and light.

One of the most well-known composite materials is carbon fiber. You might have heard of it being made use of in race cars and trucks or premium sporting activities devices. In robotics, carbon fiber is utilized to make components that are incredibly tight and solid however also very light. This is a significant benefit for a robot arm, as it allows for faster velocity and deceleration with greater accuracy. By using a compound like carbon fiber, designers can make a robot device that is a lot more effective and can carry heavier tons.

Another sort of composite material used in robotics is made by including glass fibers to a plastic polymer. This creates a product that is more powerful and more long lasting than routine plastic. These filled up plastics are typically utilized for a robot’s housing or structural panels since they provide great mechanical residential properties and dimensional security. Using a composite enables the production of a hard yet lightweight machine. The design and manufacturing opportunities with composite materials are large, letting engineers build a robot for extremely specific jobs.

When you think of a robot, you could visualize a maker made completely of metal. Nonetheless, plastics and polymers are exceptionally crucial materials in the robotics industry. They supply a series of homes that make them optimal for many different components of a robot. From the outer shell to the interior parts, you’ll find a selection of engineering plastics at the office.

One of the large advantages of plastic is that it’s lightweight. This is important for any kind of robot that requires to be mobile or energy-efficient. Consider a small, self-governing distribution robot. Making use of a lightweight plastic for its body helps it take a trip additionally on a solitary battery charge. Plastics are likewise wonderful for creating the enclosure or real estate for a robot, shielding the delicate electronics inside.

There are several kinds of plastics used in robotics, each with its very own special top qualities.

These are just a few examples, however they show how important plastic and polymer products remain in the design and manufacture of a modern robot.

I find the field of soft robotics to be among one of the most exciting locations of development. Unlike conventional robots made of rigid materials, soft robotics are made from adaptable and compliant products. This enables them to relocate and engage with the globe in brand-new and fascinating ways. At the heart of soft robotics are elastomeric materials.

Elastomers are polymers that have a distinct, rubber-like elasticity. They can be stretched to sometimes their original length and after that go back to their original shape without damaging. This residential property is what makes them excellent for producing a soft robot. Imagine a soft robotic gripper made from an elastomer like silicone. It can gently pick up a fragile object, something a standard rigid gripper could squash.

The production of soft robotics frequently involves casting these elastomeric materials right into mold and mildews. By designing these mold and mildews in certain means, designers can develop channels and chambers within the product. When air or fluid is pumped with these networks, it causes the soft robot to flex and relocate. This is a form of pneumatically-driven actuation. The advancement of new elastomeric materials is a key location of research study in material science, as it will lead to even more capable and functional soft robotic systems.

I have actually always been amazed by products that can alter their properties in feedback to their environment. These are called smart materials, and they are opening up an entire new globe of possibilities in robotics. A smart product can pick up adjustments crazes like temperature level, light, or stress and anxiety and react in a foreseeable means. This enables the production of a robot that can adapt to its surroundings.

Among one of the most fascinating types of smart materials is shape memory alloys, or SMAs. These are metals that can be curved and deformed however will return to their initial shape when warmed. A common SMA used in robotics is Nitinol, an alloy of nickel and titanium. SMAs can be utilized to create an actuator, which is a component that makes a robot action. Instead of a cumbersome motor, an easy wire constructed from an SMA can be used to create motion.

Another sort of clever material is an electroactive polymer (EAP). These are polymers that transform form when an electric field is applied. They are sometimes called “synthetic muscular tissues” because they can contract and broaden in such a way that resembles our very own muscular tissues. Using smart materials like SMAs and EAPs is a key location of study in the developing robotics area, and it will be interesting to see what brand-new robotic applications they allow in the future.

The idea of a robot that can repair itself could seem like something out of a sci-fi flick, yet it’s quickly coming true thanks to self-healing materials. These are materials that have the capacity to heal damages by themselves, similar to exactly how our skin heals after a cut. Worldwide of robotics, this could imply a robot that can take care of small scratches or fractures without needing an individual to step in.

There are a number of different ways that self-healing materials job. Some products have actually tiny capsules installed in them that are filled with a recovery representative. When the material is damaged, the capsules break open and launch the recovery agent, which then repairs the crack. Other self-healing materials are designed to be able to reform their chemical bonds after being damaged. This procedure can sometimes be set off by an external stimulus like warmth or light.

Self-healing materials are specifically promising for the field of soft robotics. Due to the fact that soft robotics are made from flexible materials, they are most likely to obtain cut or punctured. A soft robot with the ability to self-heal would certainly be far more sturdy and might be made use of in a bigger variety of atmospheres. The advancement of these ingenious products is an ideal example of just how material science is pressing the limits of what is feasible in robotics.

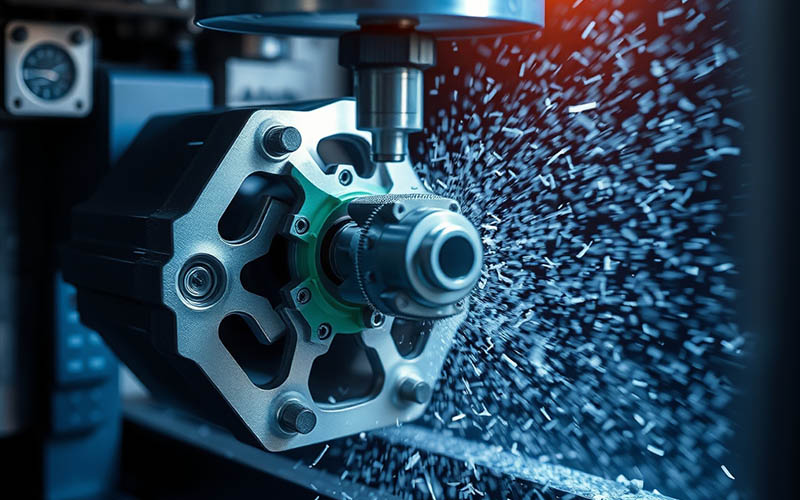

From my experience in the manufacturing world, I know that the cost of materials is a significant consider the final cost of any type of item, and robots are no exemption. The choice of products for a robot has a straight impact on its manufacturing cost. For instance, steel is a fairly inexpensive material, which is among the factors it’s so commonly utilized for the structures of industrial robots. Aluminum is extra costly than steel, but its lightweight homes can cause cost savings in other areas, such as reduced power intake for the robot’s motors.

When we start checking out high-performance products, the expense can increase dramatically. Titanium, as an example, is much more expensive than steel or aluminum. This is why it’s commonly only made use of in specialized robot applications where its special properties are absolutely necessary. Similarly, progressed composite materials like carbon fiber can likewise be expensive to produce.

The production process itself additionally contributes in the general price. Some materials are simpler to equipment and deal with than others, which can influence the labor and tooling expenses. As the robotics industry continues to grow, there will certainly be a constant demand to balance efficiency with manufacturing cost. The development of brand-new, much more cost effective materials will certainly be essential for making robotic technology extra accessible to a larger variety of industries.

The mission to create a genuinely human-like robot has actually resulted in some outstanding technologies in materials science. Humanoid robots need to be strong, lightweight, and able to move in a liquid and all-natural method. This has pressed engineers to discover new and innovative products.

One product that is coming to be increasingly vital for humanoid robots is titanium alloy. Its high strength and reduced weight make it excellent for creating the joints of a humanoid robot. For instance, 3D printing with titanium allows for the production of facility, lightweight joint parts that are additionally exceptionally strong and sturdy.

In addition to metals, progressed polymers are also playing a vital function in the development of humanoid robots. PEEK, a high-performance polymer, is being utilized to develop lightweight architectural parts. For the “skin” of a humanoid robot, soft and versatile products like silicone and thermoplastic elastomers (TPE) are made use of to provide the robot a more lifelike feel and look. These products are also utilized in soft robotics to develop grippers that can securely engage with people and objects. As we continue to establish advanced humanoid robots, we will likely see even more innovative materials being made use of.

I think that material science is the engine that is driving the future of robotics. The developments we are seeing in materials are making it possible to make and build robots that are stronger, lighter, smarter, and a lot more capable than in the past. The ongoing development of brand-new alloys, composites, and polymers is constantly broadening the toolkit that robotics engineers need to deal with.

The connection between robotics and products is a two-way road. The needs of the robotics industry are pressing material researchers to create new materials with details residential or commercial properties. As an example, the need for more energy-efficient robots is driving the growth of lightweight products like aluminum and carbon fiber. The desire for robots that can work safely alongside people is sustaining the growth of soft robotics and the development of elastomeric materials.

In the future, I expect to see much more remarkable products being used in robotics. We may see robotics made with biomimetic materials that are inspired by nature. Envision a robot with a skin that can transform color like a chameleon or a robot that can relocate with the performance of a bug. The opportunities are limitless, and it’s a really amazing time to be enjoying the fields of robotics and material science collaborated.

As we have actually discovered the varied world of robotics products, a few key points stand out. The choice of products is a crucial aspect of robot style and has a significant effect on performance, expense, and capacities.

Below are some of the most essential things to bear in mind:

The robotics market is constantly advancing, and the materials that are made use of to develop robotics will certainly continue to develop with it. From the rigid materials that give a robot its strength to the soft and smart materials that give it new abilities, the future of robotics is fundamentally connected to the future of material science.