Deje que Istar le ayude a poner en marcha su proyecto con nuestra experiencia y conocimientos.

Cargue sus archivos de diseño y requisitos de producción y nos pondremos en contacto con usted en menos de 30 minutos.

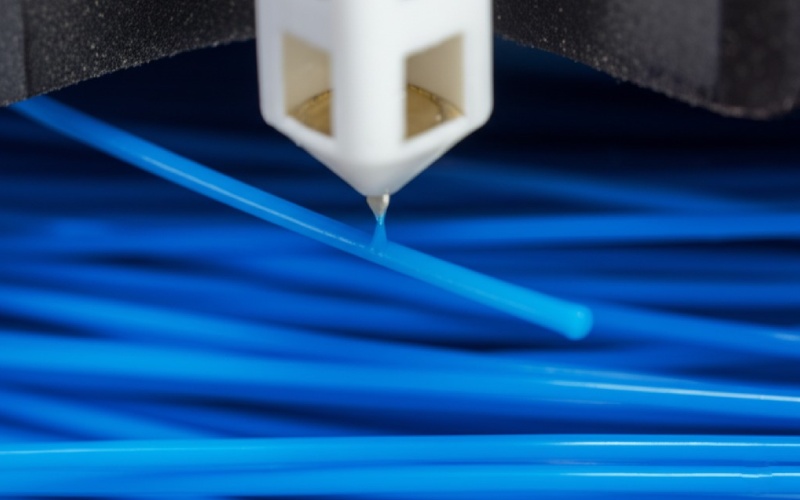

Picking the right filament is a very big part of getting a good 3d print. In this article, I am going to explain the choice of PLA vs. ABS using simple words. We will look at the main differences between these two common materials. When you are done reading, you will know for sure which filament should you use for the thing you want to make next. You will save time, use less material, and create better printed parts right from the start.

Let’s begin with the simple facts. What are these plastics? Both PLA and ABS are a kind of plastic called a thermoplastic. That is a big word that just means you can heat them up to make them soft and then let them cool to make them hard again. Your 3D printer does this again and again to build your part, one layer at a time. They are two of the most common popular materials in the world of 3d printing.

First, we have Polylactic Acid, or PLA. This is likely the most used 3d printing filament. I think it is neat that it is made from things that can grow again, like cornstarch or sugarcane. This makes it a little better for the earth. People know it is easy to work with. The second filament is Acrylonitrile Butadiene Styrene, or ABS. You have seen ABS plastic your entire life. It is the same strong plastic used for LEGO bricks, the insides of cars, and the keys on a computer. It is known for its strength and how long it lasts.

When you are at your printer, you need to know how PLA and ABS act in different ways. The difference between pla and abs is about a few main things. These things change everything from how you 3d print the material to what you can use the finished part for. I have learned that knowing these differences is what helps you do a good job.

I created a simple table to help you see the main differences next to each other. This is a great list to keep close to your 3d printer. Choosing between PLA and ABS gets a lot easier when you see it all in one place.

| Característica | PLA (ácido poliláctico) | ABS (acrilonitrilo butadieno estireno) |

|---|---|---|

| Ease of Printing | Very easy, good for people just starting out. | Hard, needs a heated bed and a cover. |

| Temperatura de impresión | Lower (190-220°C nozzle) | Higher (210-250°C nozzle) |

| Deformación | Very little chance to warp. | High chance to warp if the bed is not heated. |

| Fuerza | Stiff and strong, but breaks easily. | Not as stiff, but tougher and handles bumps well. |

| Resistencia al calor | Poor. Becomes soft around 60°C (140°F). | Good. Can withstand up to 100°C (212°F). |

| Smell When Printing | Sweet smell, like sugar that is cooking. | Strong, bad smell of hot plastic. |

| Biodegradable | Yes, in special industrial composters. | No, it is made from oil. |

| Finishing the Part | Hard to make smooth. You have to sand it. | Easy to make smooth using acetone gas. |

If you are just starting out with 3D printing, I have some simple advice: begin with PLA. PLA is easy to print. I know this from my own experience. It lets you make mistakes. It has a lower printing temperature, which means it comes out of the printer nozzle nicely without needing to be super hot. The best part is that it does not warp very much. Warping is a big problem where the corners of your 3d print lift up and curl as they get cool. PLA helps you stop this from happening.

On the other hand, ABS can be hard to use. I can still remember my first time trying to print ABS. Many of my prints did not work. The big problem is that ABS tends to get smaller as it cools down. This shrinking pulls the 3d print up and makes it warp. To stop this, ABS requires a heated print bed that is set to a higher temperature. It also helps to put your 3d printer inside a box or cover to hold the heat in. For someone who is new, this is a lot of more things to do. So, when we talk about ease of printing, PLA is the clear winner. It is much easier to print.

Temperature is a very big deal for a good 3d print. For PLA and ABS, the settings are not the same at all. PLA uses a lower printing temperature. You will most likely print PLA filament with the nozzle at about 190°C to 220°C. The print bed can be set to a low heat, around 20°C to 60°C, if you heat it at all. Because of this, PLA works with almost any 3d printer you can buy, even the really simple ones.

To do a 3d print with ABS filament, you need more heat. The nozzle must be hotter, usually somewhere between 210°C and 250°C. The print bed is something you have to use; it must be heated to about 80°C to 110°C. This high heat keeps the first layers of the 3d print warm and stuck down, which is the best way to stop a warp. The point where a plastic begins to get soft is called its glass transition temperature. PLA has a lower glass transition temperature than ABS. This is why it needs less heat to print. It is also why it cannot deal with hot places.

I get this question all the time: which one is stronger, PLA or ABS? The answer is not that simple. This is because “strong” can mean a few different things. We should look at the mechanical properties of PLA and ABS filaments, or how they act when pushed or pulled. When we talk about tensile strength, which is how much you can pull something before it breaks, PLA is in fact stronger than ABS. A part made with PLA is very stiff and does not bend easily.

But, a pla part is also more brittle, which means it breaks easily. When it gets to its breaking point, pla will break all of a sudden, like a piece of glass. It will snap right in two. ABS is less stiff, but it is much tougher and lasts a long time. It has better flexural strength, which means it can bend a bit before it breaks. Think of it like this: if you need a part to hold something heavy and not move, PLA is a good choice. But if you need a part that might get dropped or hit, ABS is better. The strength of parts printed in ABS makes them good for things that have a real job to do.

For this, it’s easy to see which is better: ABS has better heat resistance. Like I said before, PLA has a low glass transition temperature of about 60°C (140°F). I learned this lesson the hard way. I left a phone stand I made with a pla filament in my car on a hot day. When I came back, it was a droopy, melted blob of plastic. PLA cannot deal with high temperatures.

But, ABS is commonly used for parts that will get hot. ABS has a higher glass transition temperature of about 105°C (212°F). This makes ABS a much better choice for parts that will be in cars, near electronics, or outside in the sun. If your 3d print must withstand heat, you have to use ABS. This ability to handle high heat resistance is a big reason why people do the extra work to print with ABS filament.

How your final 3d print looks is a big deal. This is especially true for models or models you look at. Right after it is made by the printer, pla typically provides a smoother surface finish that is a little bit shiny. The lines between the layers can be harder to see. This is wonderful for parts that need to look good. A 3d print made with PLA often looks nice with no extra steps.

ABS parts usually have a flat, not shiny, finish when they are first printed. The really neat thing about ABS, however, is what you can do after the 3d print is finished. You can use a liquid called acetone to make the surface smooth. If you put the ABS parts in a box with acetone gas, the outside layer melts just a tiny bit. This makes the layer lines melt together. It gives you a very, very smooth, shiny surface that looks like it was made in a factory, not printed. This is a big plus for making a prototype that looks like a real product.

One of the big reasons people like PLA is because they say it is biodegradable. This is true, but there’s a trick to it. PLA is made from plants, which is good. It is a biodegradable plastic because, in the right place, tiny living things can break it down. But, that “right place” is a special, very hot compost place, not the compost pile in your yard. So, it is better for the earth than plastics made from oil. But it will not just go away if you throw it out.

On the other hand, whereas abs is made from oil, it is not a green option. ABS is not biodegradable. It will stay in the ground for many, many years, just like other plastics. So, if how your 3d print affects the earth is something you care a lot about, PLA is the better choice of the two materials, even with that small problem about composting. It is a good step toward a better 3d printing material.

So, after reading all of that, when should you pick ABS or PLA? You should pick ABS filament when the thing you are making needs to be strong, tough, and handle heat. I prefer ABS for parts that have a real job to do, not just ones that look nice. It is the right filament for a lot of different variety of applications where how it works is most important.

Here are some times when you should use ABS:

The applications of ABS are often for parts that must hold their shape and not break, and also not be harmed by chemicals. The toughness of abs also makes it a choice you can count on.

Now let’s talk about PLA. It might not be as tough as ABS, but it is great for many other kinds of tasks. Its ease of printing makes it the first material people choose for a lot of different projects. For anyone who makes things, having PLA ready to go is needed for a fast and simple 3d print. The amazing detail you can get with PLA is good for difficult models.

Here are some times when you should use PLA:

PLA is typically the best choice when how your 3d print looks matters more than how strong it is. When I need to make a fast prototype, I always choose PLA.

Choosing the right filament can seem hard, but it is all about what you are making. Choosing between abs and PLA is a basic skill in the world of 3d printing. To make your next project turn out great, just keep these main points about PLA and ABS in mind: