Deje que Istar le ayude a poner en marcha su proyecto con nuestra experiencia y conocimientos.

Cargue sus archivos de diseño y requisitos de producción y nos pondremos en contacto con usted en menos de 30 minutos.

Sheet metal bending is a big part of sheet metal fabrication. We take a flat piece of metal and bend it to make a new shape. It may sound easy, but doing it right takes a bit of skill. This article is my way of sharing what I have learned over time. I will give you my best tips to help you understand more about sheet metal bending. You will learn how to design great parts, stay away from common problems, and make the whole job easier. This will help you save time and create better sheet metal part designs.

In my years in this line of work, I have seen sheet metal bending used to make all kinds of things. It is used for everything from small brackets to big boxes. It is a process where we put pressure on a piece of sheet metal. This pressure makes the metal change its shape and bend at an angle. This is one of the most popular ways we make a sheet metal part. The main idea is to change the shape of the flat metal sheet. We turn it into a helpful 3D part, and we do it without cutting any metal away. It’s a basic part of all sheet metal fabrication.

You can think about a metal box. That box probably started as a flat piece of metal. A few planned bends were made to form it into the shape you see. This is the cool thing about sheet metal bending. We use this process for many different kinds of products. We see it in the automotive world, in electronics, and in building things. It’s a quick and good way to make a strong metal part that is also lightweight. This sheet metal bending process lets us make parts very fast.

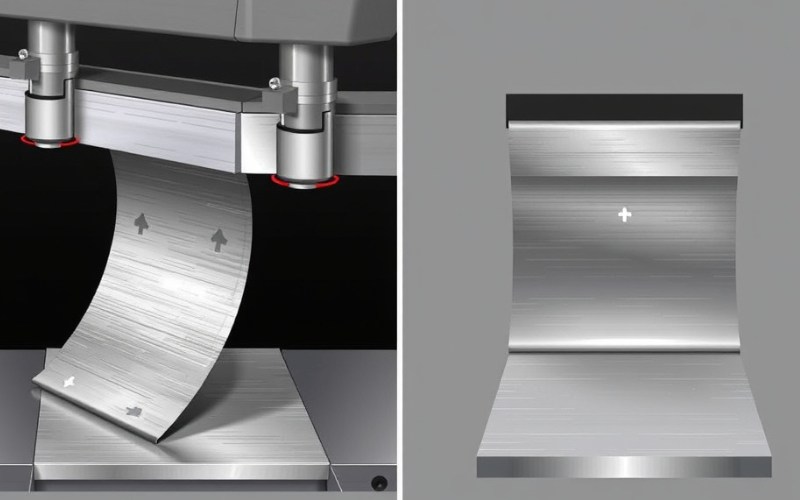

The tools that are used to bend the sheet metal are very important. Most of the time, we use a machine that is called a press brake. This machine holds the metal in place. Then, it uses a punch to press the metal into a tool called a die. This is what creates the bend. There are many kinds of bends we can make. We can do a simple V-bend, a U-bend, or even a shape that has a curve. The kind of bend we need and the thickness of the metal will decide how we set up the machine. This helps get the job done right for the best sheet metal bending. It is a very basic skill you need to have when working with any kind of metal.

This is super important: a good design at the very start will save you from a lot of problems later on. When you design a sheet metal part that needs bending, you are making a set of instructions. These instructions tell the machine how to bend the metal. A good sheet metal design thinks about the metal being used, the tools for the job, and what sheet metal bending can and cannot do. If the design is not good, you can get parts that are cracked. You might get wrong angles, or you could end up with a sheet metal part that does not fit where it is supposed to go.

A design that is well thought out looks at every single bend. It thinks about the bend radius, the material thickness, and where holes or a slot should go. For instance, if you put a hole too close to a bend, it can get stretched out of shape. A good design will add small relief cuts. These cuts stop the metal from tearing when it is bent. These small details in the sheet metal design part of the job are very important for the quality of the final sheet metal part. A good design will give you a stronger part. It will also have a lower cost to make and will take less time to get finished.

Thinking about the sheet metal bending work while you are still in the design stage is the most important thing. You have to think like the person running the press brake. Can the machine really make the bends you have put in the design? Is there space for the tool to get in and do its job? A simpler design is usually a better design. Trying to make a shape with a lot of details in one piece of metal can be hard to do. Sometimes, it is a better idea to make two metal parts that are simpler. Then you can weld them together. A good design makes producing parts a simple job that you can do over and over again the same way.

When we talk about sheet metal bending, there are a few common ways to get it done. The bending method you pick will depend on the material. It also depends on its thickness and the final angle you need to make. The most popular bending method is called air bending. I use air bending for many of my projects. This is because it can do many things and does not need as much force as other ways.

With air bending, the punch pushes the metal down into the die. But the metal never fully touches the bottom part of the die. It only touches the two top edges of the die and the very tip of the punch. This makes a “V” shape. We can control how far down the punch pushes the metal. This lets us create many different angles using just one set of tools. This makes air bending a bending method that saves a lot of time. It is a great choice for parts made of steel and aluminum.

There are other methods, like bottoming and coining. In bottoming, the punch presses the metal down so it fits tightly against the die. This gives you a very exact angle and also lowers springback. We will talk more about springback later. Coining uses even more force. The punch pushes down so hard that it actually makes the metal thinner where the bend is. This gives a very sharp and correct bend. But, it needs a lot of power and can be tough on the tools and the metal. For most jobs, air bending is a good mix of being exact and saving time. It’s the most commonly used bending method for sheet metal bending.

The press brake is the main tool we use for sheet metal bending. I have used many different kinds, from old ones you work by hand to newer CNC machines. A press brake is a machine that is used to bend sheets of metal. It has a long part on top with a punch and a die on the bottom. We put the flat metal sheet in between the punch and the die. The punch then comes down with a lot of pressure. This pressure pushes the metal into the V-shaped opening in the die. That is how the metal is bent.

Newer machines are often CNC controlled. CNC stands for Computer Numerical Control. This means a computer runs the whole sheet metal bending job. An operator puts the design file into the computer. Then, the CNC press brake can change the force and position all by itself to make a perfect bend every single time. This lets us be very exact and make the same part again and again. We can make thousands of the same sheet metal part that are all within a very small tolerance. The CNC computer also helps us plan for things like springback. This makes sure the final angle is right.

The press brake tool set, which is the punch and die, is also a big deal. They come in many shapes and sizes. A straight punch and a basic V-die are commonly used. But for special jobs, we might use a gooseneck punch to bend a shape with a lot of details. Or we might use a special die to make a curve. The tool we pick depends on the metal thickness, the bend radius we want, and the final shape of the sheet metal part. Using the correct tools is a must for good sheet metal bending.

When you bend a piece of metal, you do not get a corner that is perfectly sharp. You get a corner that is rounded, like a curve. The radius of that curve on the inside part of the bend is called the bend radius. This is a very important rule in sheet metal design. If you try to make the bend radius too small for the kind of metal or its thickness, a problem can happen. The metal on the outside of the bend can stretch too much and break.

A good general rule of thumb is to make the bend radius at least the same as the material thickness. For example, let’s say you have a piece of steel that is 2 mm thick. Your smallest bend radius should be 2 mm. This helps to stop cracking and makes sure you have a strong and clean bend. Some kinds of metal, especially a harder alloy, need a bend radius that is even bigger. Softer metal like aluminum can usually be bent with a smaller radius.

You have to clearly say what the bend radius should be in your design. If you do not, the shop making the part will probably just pick a standard radius for you. This might not be what you wanted. It is also a good idea to have the same bend radius for all the bends on one sheet metal part. This makes the job simpler. It means the press brake worker does not have to change the machine’s setup. Paying attention to the bend radius is a small step in the design that is very important for your sheet metal bending project.

The kind of metal you pick is one of the most important choices for any sheet metal bending project. Different metals act in different ways when you try to bend them. Their features, like how strong they are, how easy they are to shape, and their stiffness, will decide how easy they are to work with. I have worked with many different metal types over the years.

Here is a simple table showing some common sheet metal materials:

| Tipo de metal | How It Bends | Dónde se utiliza |

|---|---|---|

| Acero dulce | Strong, simple to bend, costs less. Can get rusty if not coated. | General metal work, car parts |

| Acero inoxidable | Very strong, great corrosion resistance. Harder to bend, needs more force. | Kitchen tools, medical parts |

| Aluminio | Lightweight, good corrosion resistance. Softer and simpler to bend than steel. | Airplanes, electronics, signs |

| Acero galvanizado | Mild steel with a zinc coating to protect it. Bends nicely, good at stopping rust. | Outdoor boxes, roofing |

| Cobre | Very soft and simple to bend. Perfect for electrical jobs. | Wires, pipes |

When you pick a metal, you need to think about what it will be used for in the end. If you need a strong part for an automotive job, mild steel or a steel alloy could be the best choice. If you need a part that is lightweight for a plane, aluminum is the right answer. For a part that will be near water, the chromium in stainless steel is great because it stops rust. The type and thickness of the metal will have a big effect on the sheet metal bending job, so pick carefully.

Springback is something I have to explain to people all the time. It is something that just happens during sheet metal bending. When you bend a piece of metal, you stretch the outside part and the inner surface gets squeezed. After you let go of the bending pressure from the press brake, the metal wants to go back to its old shape a little bit. This is what we call springback.

So, if you want to bend a piece of metal to a perfect 90-degree angle, you might have to bend it to 92 or 93 degrees first. When you let it go, it will springback to the 90-degree angle you wanted. The amount of springback is not the same for every metal. Harder metals like high-carbon steel and stainless steel have more springback. Softer metals like aluminum or copper have less. A thicker piece of metal will also have more springback.

Workers who have a lot of experience with a brake know how to handle springback. We can figure out how much it will be and change the bend angle to plan for this change. This is often called over-bending. CNC press brake machines are very good at this. They can be programmed to automatically over-bend by the right amount for a certain metal and thickness. Knowing how to deal with springback is a key skill for getting it just right in sheet metal bending. If you ignore it, you will for sure get the wrong angle on your sheet metal part.

Now we are getting to a part of sheet metal bending that has more details: the k-factor. The k-factor is a number that is used to figure out how much the metal stretches when it is bent. When metal is bent, the inside and outside parts change. The outside part stretches, and the inside part gets squeezed. Somewhere in the middle of the metal thickness, there is a line that does not stretch or get squeezed. This line is called the neutral axis.

The k-factor is a number that compares the location of the neutral axis to the material thickness. This number helps us figure out the “bend allowance.” The bend allowance is the length of the bend’s curve. Knowing this lets us figure out the correct length of the flat sheet metal part before we bend it. This is called the flat pattern. If your flat pattern is wrong, your final bent part will have the wrong dimension.

For most common metals like steel and aluminum, the k-factor is usually a number between 0.33 and 0.50. You do not always have to figure out the k-factor by hand. Most design programs for sheet metal bending have lists with standard k-factor numbers for different materials. Using the correct k-factor is very important. It helps you make a correct flat pattern, which then gives you a correct sheet metal part after sheet metal bending.

Over all my years, I have learned some rules that make sheet metal bending go a lot easier. If you follow these design tips for bending, you can save yourself from a lot of problems. A good design is the first step toward making a great sheet metal part.

Here are some tips I always use for my sheet metal bending work:

I have seen every kind of problem when it comes to sheet metal bending. Most mistakes are because the design did not think about how we really bend metal. A common mistake is asking for a bend radius that is too sharp. This causes cracks and makes parts weak. Always look up the smallest bend radius you can use for your material type.

Another mistake is not thinking about springback. A designer may draw a perfect 90-degree angle. But they do not think about the metal springing back. This leads to a sheet metal part that does not fit correctly. You should always talk to the sheet metal fabrication shop about tolerance. Ask them how they handle springback for the metal you want to use. The sheet metal bending process has to plan for this.

Finally, making parts that have too many details can lead to big problems. Sometimes a design has bends that are too close to each other. Or it might have a part that gets in the way of the press brake tools. This is where having experience helps. A sheet metal bending expert can look at a design and see these problems right away. My advice is to keep your design as simple as you can. It will make the sheet metal bending job cost less, go faster, and be something you can count on. This is how you get great results when you bend metal.

Here are the most important things you should remember about sheet metal bending: