Deje que Istar le ayude a poner en marcha su proyecto con nuestra experiencia y conocimientos.

Cargue sus archivos de diseño y requisitos de producción y nos pondremos en contacto con usted en menos de 30 minutos.

In the world of machining, basic materials are changed into the exact parts that help our world run. I have seen with my own eyes how a piece of metal can become a very important part of a plane or a car. In this article, I want to tell you about the different kinds of machining processes I have learned about. We will look at the old methods that people have used for many years. We will also look at the new technologies that are changing how things are made. When you finish reading, you will understand how these great machining operations turn basic materials into the detailed parts we use all the time.

A machining process is a way of making things. It uses a cutting tool to take away material from a piece of work. You can think of it like a sculptor carving a statue from a block of stone. The sculptor takes away stone to make the final shape. A machining process does something similar. It takes away material from a workpiece. This creates a part with the right shape and size. This is the reason people call machining a subtractive manufacturing process.

It is the other way around from additive manufacturing. An example of that is 3D printing, where you add material to build something. The main goal of any machining process is to make a part with high precision and a good surface finish. Precision means the part’s size is almost exactly what it needs to be. Surface finish is about how the surface of the part feels. A smooth surface is very important for parts. These parts might need to fit together just right. Or, they might get a lot of use and rubbing. The world of machining is very big. There are many different machining techniques and machining operations.

In the field of making things, there are many kinds of machining processes. But we can put them all into two main groups. These are conventional machining processes and non-conventional machining processes. The biggest difference between these two groups is the way they take material away from a workpiece.

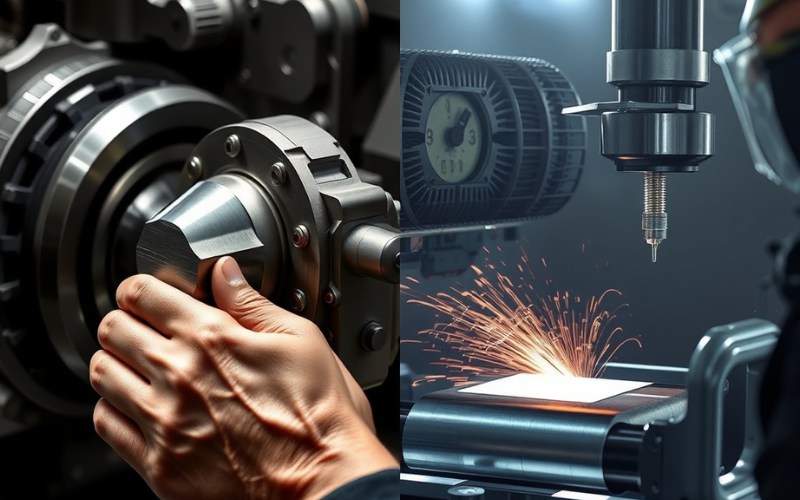

A conventional machining process means the cutting tool directly touches the workpiece. You can think of it like peeling an apple with a knife. The knife is the cutting tool. The apple is the workpiece. The knife touches the apple to take off the skin. In a similar way, conventional machining operations use a sharp cutting tool. This tool cuts away the material. A non-conventional machining process is different. The tool and the workpiece do not touch. Instead, these processes use other kinds of energy to remove material. This can be heat, chemical, or electrical energy.

A conventional machining process is the most common and oldest type of machining. In this process, a cutting tool has to touch the workpiece to take away material. You can use this process for many kinds of materials. For example, it works on metals, plastics, and wood.

There are several types of conventional machining operations. Some of the most well-known are turning, milling, and drilling. The turning process is used to make round, cylinder-like parts. In this process, the workpiece spins while a cutting tool that stays in one place removes material. Milling is a very useful machining process. It uses a spinning cutting tool to take material away from a workpiece that is not moving. You can use this process to make flat surfaces, slots, and other detailed shapes. Drilling is a process that makes round holes in a workpiece. It uses a tool called a drill bit.

A non-conventional machining process is a newer type of machining. In this method, the cutting tool and the workpiece do not touch each other. Instead, these processes use different kinds of energy to take material away from a workpiece. This makes these processes great for working on very hard or fragile materials. These materials are hard to cut with the usual methods.

There are many different types of non-conventional machining processes. Each one has its own special benefits. Some of the most common non-conventional processes are:

These are just some examples of the many non-conventional machining processes that are used today to make things.

A CNC machine has completely changed the machining process. CNC stands for Computer Numerical Control. Before, machining operations were done by hand. A skilled person, called a machinist, had to control the cutting tool’s movements. To get high precision, the person needed a lot of skill and practice. With a CNC machine, the whole machining process is automatic.

A computer program controls a CNC machine. This program tells the cutting tool exactly how to move. This gives you much better precision than doing it by hand. The parts are also more alike. The process starts with a computer drawing of the part. This can be a 2D or 3D drawing made with CAD software. Then, this drawing is changed into a special computer code. The CNC machine can read this code. The code gives the machine instructions. It says where the cutting tool should go and how fast it should move. Because it is so automatic, it is possible to make very complex parts. These parts can have very exact measurements. You can use a CNC machine for many machining operations. These include milling, turning, and drilling.

The main difference between conventional and non-conventional machining is how material is taken away from the workpiece. In a conventional machining process, a sharp cutting tool makes direct physical contact with the workpiece to cut material away. This is a physical process. It works because the cutting tool is harder than the workpiece material.

A non-conventional machining process is different because a tool does not touch the workpiece. These methods use other kinds of energy to remove material. This can include heat, chemical, or electrical energy. Because there is no direct touching, the tool wears down very little in non-conventional machining processes. This makes them very good for working on materials that are very hard or tough to cut.

Here is a table that shows the main differences:

| Característica | Conventional Machining | Non-Conventional Machining |

|---|---|---|

| How Material is Removed | Direct contact with a cutting tool | No direct contact; uses different kinds of energy |

| Desgaste de herramientas | A lot of wear | Very little to no wear |

| Good For These Materials | Softer materials | Hard and fragile materials |

| Type of Energy Used | Physical force | Heat, chemical, or electrical energy |

There are many different kinds of machining operations. Each is made for a certain job. These operations can be put into two general groups: conventional or non-conventional. The most common conventional machining operations include:

Besides these basic operations, there are other important machining processes. Finishing operations, for instance, are used to make the surface of a part smoother and its size more exact. Grinding is a common finishing process. It uses a grinding wheel to get a very smooth surface.

Yes, there are two main kinds of milling operations: face milling and peripheral milling. The kind of milling operation you use depends on the shape you want for the final part.

Fresado frontal is used to make flat surfaces on a workpiece. In this process, the sharp edges on the end of the milling tool are used to take away material. This is often a first step to make a surface flat. This is done before other machining work.

Fresado periférico, on the other hand, uses the sharp edges on the sides of the spinning cutting tool to take away material. This process is used to make slots, grooves, and other shapes on the workpiece. An end mill is a common kind of cutting tool used in peripheral milling. CNC milling often uses a method called climb milling. In this method, the workpiece moves in the same direction that the cutter is spinning. For milling done by hand, people usually use conventional milling. Here, the workpiece moves in the opposite direction of the spinning cutter.

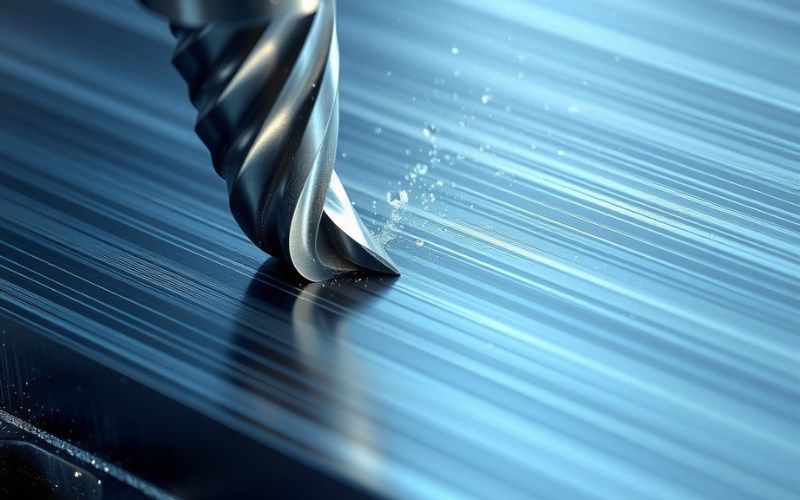

The cutting tool is one of the most important parts in any conventional machining process. It is the tool that directly touches the workpiece to take away material. How well a machining operation works depends a lot on the cutting tool. Its quality and design are very important.

Cutting tools are made in many different shapes and sizes. They are also made from different materials. The right cutting tool depends on a few things. These are the type of machining operation, the material you are cutting, and how smooth you want the surface to be. For example, a drill bit is a type of cutting tool used for drilling. An end mill is used for milling operations.

The material of the cutting tool is also a very important thing to think about. Cutting tools need to be harder than the material they are cutting. Common materials for cutting tools are high-speed steel, carbide, and diamond. The shape of the cutting tool is also very important. For example, the angle of its sharp edge makes a big difference in how well the machining process works.

Electrical discharge machining (EDM) is a type of non-conventional machining process. It uses electrical sparks to remove material from a workpiece. It is also sometimes called spark machining or discharge machining. This process is great for working on hard materials that can conduct electricity. These materials are tough to cut with normal methods.

In the EDM process, the workpiece and an electrode are put into a special liquid that doesn’t conduct electricity. Then, many electric sparks are made. They jump between the electrode and the workpiece. These sparks create a lot of heat. This heat melts the material and turns it into a gas. This is how the desired shape is made. Because the electrode and the workpiece do not touch, the tool does not wear down. This allows for the making of complex shapes with very high precision. Electrical discharge machining is a very important process for making molds and dies.