Laissez Istar vous aider à démarrer votre projet avec notre expérience et notre savoir-faire !

Téléchargez vos fichiers de conception et vos exigences de production et nous vous répondrons dans les 30 minutes !

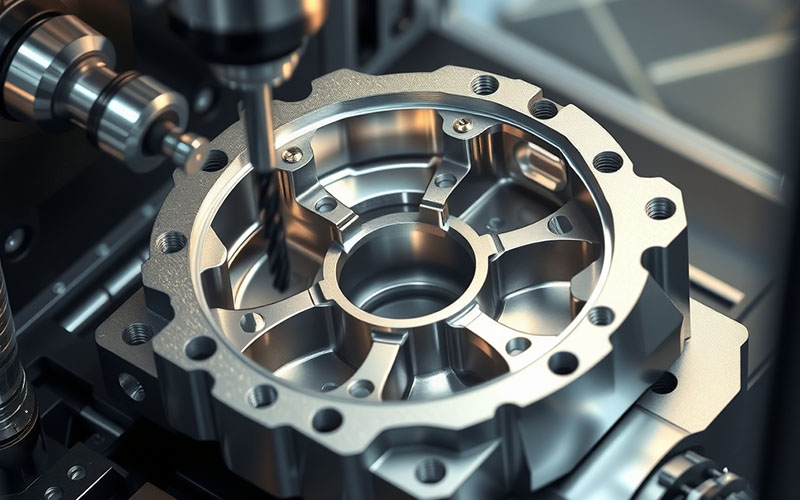

A big CNC machine looked very hard to understand. What were all those axes for? What did they let the machine do? In this guide, we will look at everything from a basic 3-axis CNC machine to an amazing 12-axis CNC machine. You will find out what each machine can do. You will see why having more axes can make a machine much better. This article will explain it all in a very simple way.

Let’s begin with the simple things. When people talk about the axes of a CNC machine, they are talking about the ways it can move. Picture a square box. The machine can move its tool from side to side. That is the X-axis. It can move it from front to back. That is the Y-axis. It can also move it up and down. That is the z-axis. These are the three main axes that you will find on every CNC milling machine.

But a CNC machine with more features can do more. It can also make the part it is working on turn or spin. This turning motion is called rotation. Every new turning motion adds more axes. An axis of rotation lets the machine get to the part from new angles. We call these turning axes the A-axis, B-axis, and C-axis. The more axes a machine has, the more detailed a part it can create. This is the most important part of understanding what a machine is able to do.

A 3-axis CNC machine is the most common kind of CNC machine. I see them in workshops all the time. This machine works with the basic X, Y, and Z axes. The cutting tool moves up and down, from side to side, and from front to back. On this simple machine, the piece you are cutting does not move. The part is held down flat while the cutting tool moves around and does all the work. It is great for easy jobs. A 3-axis CNC milling machine is perfect for things like drilling holes, milling slots, or cutting sharp edges on a flat part.

Here is an easy way to think about it. A 3-axis machine can cut something on the top of a block of wood. It can carve a name on it or cut out a shape that is flat. But it can’t get to the sides or bottom of the block easily. To do that, you have to stop the machine. Then you have to take the part out and set it up again in a new way. This uses up time and can cause errors. This is the biggest weakness of a 3-axis CNC. It is a very helpful machine, but it is best for easier shapes. The 3 axes keep the work simple.

Next, let’s look at the 4-axis CNC machine. This machine is a step up from the last one. It has the same three axes (X, Y, Z) that a 3-axis machine has. But it also adds one more. It adds an axis of rotation. This is often called the A-axis. This additional axis lets the machine spin the part that it is cutting. This is a very big improvement!

With a 4-axis CNC, the machine can now work on the sides of a part. And it can do this without the need to stop and set it up again. Think about making a leg for a table. A 4-axis milling machine can carve nice details all the way around the leg. It does this by turning the part within the machine. This gives it a big lead over the 3-axis counterpart. The main drawback of 4-axis milling is that it usually only offers one kind of rotation. Even so, this machine gives you many more ways to make parts.

The 5-axis CNC machine is where things get really interesting. I think this type of machine changed the game. A 5-axis machine has the three basic axes (X, Y, Z). It also adds two axes of rotation. This is what makes a 5-axis CNC milling machine able to do so much. It has rotations around two additional axes. The machine can tilt its tool. At the same time, it can also spin the part. This allows the machine to cut shapes that are very hard to make.

With a 5-axis milling machine, you can make parts with deep spots and sloped sides. These are impossible with 3-axis machines. This is because the tool can always be at the perfect angle to the part. You can make very detailed parts all in one go, without stopping. This is called a single setup. This saves a lot of time. It also makes the cuts more exact because you are not moving the part with your hands. The 5-axis machine is a very useful tool for any shop that takes its CNC machine work seriously.

You may think that 5 axes are all you need, but we can go even further. Let’s talk about the 7-axis CNC and 9-axis CNC machines. A 7-axis CNC machine is usually a 5-axis machine with one more special move. It adds a rotation of the tool head. This means the tool itself can spin and turn. A 7-axis CNC machine can make parts that are even more detailed. These are often used for jobs that need special skills, like making parts for the aerospace field.

A 9-axis CNC machine is an even more powerful machine. These machines typically contain two heads, or spindles. You can picture it as two different machines working on the same part at once. A 9-axis CNC machine could have a 5-axis head and a 4-axis head working side by side. This is a reason why a 9-axis CNC is so highly capable. It can do milling and turning work on the same part at the same time. The great things about a 9-axis CNC are its amazing speed and its ability to finish a very tricky part in one operation. The precision of this CNC machine is top-notch.

When I first heard about a 12-axis CNC machine, I thought it was a joke. How can a single machine have 12 axes? It sounds like something from a movie, but it is a real thing. A 12-axis CNC is often two 6-axis systems working side by side. Think of two robot arms. Each arm has 6 axes of movement. They work on the same part from opposite sides. This kind of machine is the best at making tricky parts. The given machine can have many rotations and translational movements.

These very smart CNC machines might have extra axes known as U and W axes. These give the machine extra straight-line movements. The main reason for 12-axis machining is to finish the hardest parts you can think of in just one operation. This doubles productivity and accuracy. You will find a 12-axis CNC machine making parts for the aerospace and military industries. This machine provides a level of detail that no other machine can come close to. This machine represents the very best of today’s technology.

This is a very good question. Why does giving a CNC machine more axes make it better? The important word here is precision. This means making sure every cut is exact. Each time you stop a milling machine to move the part by hand, there is a chance of making a small mistake. Your new setup might be off by a tiny amount. After many new setups, these small mistakes build on each other. A multi-axis CNC machine gets around this issue.

A 5-axis CNC machine, as an example, can cut a part on five different sides. You never have to touch it. This is called a single setup. Because the CNC machine holds on to the part the whole time, the precision is much better. The part you make at the end is more true to the design. A machine with more axes can also use cutting tools that are shorter and stronger. This makes the tool shake less and gives a smoother, more exact finish. So, more axes leads to fewer setups. And fewer setups leads to better precision. The number of axes is very important for a high-quality CNC machine.

Sometimes, a chart can explain things better than many words. Here is a simple way to compare the 3-axis to 12-axis machines.

| Number of Axes | Movements | Utilisations courantes |

|---|---|---|

| 3-Axis CNC | X, Y, Z (Up/Down, Side/Side, Front/Back) | Flat parts, drilling holes, simple cuts. |

| 4-Axis CNC | X, Y, Z + A-axis (rotation around X-axis) | Designs on tubes, side cuts, cams. |

| 5-Axis CNC | X, Y, Z + A-axis + B-axis (rotation) | Complex shapes, aerospace parts, medical devices. |

| 7-Axis CNC | 5 axes + tool head rotation + another axis | Parts needing very fine intricate detailing or depth. |

| 9-Axis CNC | Two spindles working together (like 5+4) | Both milling and turning, very fast work. |

| 12-Axis CNC | Two 6-axis heads working at the same time | The hardest mechanical parts you can imagine. |

This chart helps to show how every additional axis gives the machine a new set of skills. There are many different types of CNC machines for different tasks.

You might ask who really needs a 12-axis CNC or 9-axis CNC machine that costs a lot of money. For most shops, a 3-axis machine or a 5-axis machine is all they need. But for certain jobs, you must have the best machine you can get. The aerospace industry is a great example. A part for a jet engine can have very tricky shapes. You need a multi-axis CNC milling machine to make it with perfect precision.

This is also true for medical devices. Think about a new hip or knee joint made for a person. It must be perfectly smooth. Its shape has to be exactly right. A very good CNC machine with many axes is needed for this kind of work. The military also uses these advanced CNC machines. They use them to make high-tech parts. When people’s lives are at stake, you need the best precision you can get from a machine. I once saw a company use a 7-axis CNC to create a geneva mechanism with amazing precision.

So, after learning all of this, how do you pick the right CNC machine? I have a simple rule: use the easiest machine that can do the job well. Do not buy a 12-axis CNC if you only plan to make flat signs. A good 3-axis milling machine will be perfect and will save you a lot of money. The kind of CNC project you have will tell you what CNC machine you should get.

If you begin to make parts that have sloped holes or cuts on the side, it may be time to get a 4-axis CNC or 5-axis CNC machine. The idea is to pick the machine that fits how hard the part is to make. If you are not sure, you can always speak with a Service d'usinage CNC. They are experts in CNC services suitable for any kind of project. They can help you choose. They are familiar with the different types of CNC machines available. The CNC machines on the market are made for certain kinds of jobs. Picking the right machine is the first thing to do to make sure your project is a success. The CNC controller on any machine is also very important for its final precision.