Laissez Istar vous aider à démarrer votre projet avec notre expérience et notre savoir-faire !

Téléchargez vos fichiers de conception et vos exigences de production et nous vous répondrons dans les 30 minutes !

“What is the difference between a CNC lathe and a CNC turning center?” This is a good question. People often use both names for the same thing, but they are not the same. In this article, I am going to explain it all for you in a simple way. We will look at what each machine does. We will see what makes them different. We will also learn when you should use one machine instead of the other. When you finish reading, you will understand the main differences. You will be able to talk about them like you have been doing this for years. You will know for sure which machine you need CNC for your specific machining process.

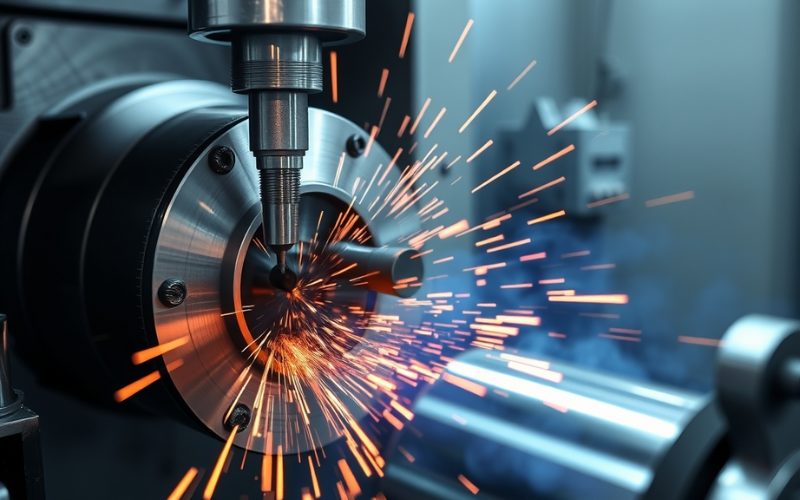

Let’s begin with the simple things first. A CNC lathe is a kind of machine tool that has been around for a very long time in different ways. The main idea is easy to understand. You take a piece of material, which we call a workpiece. You hold it in a part called a chuck that spins. The spindle makes the workpiece rotate very fast. Next, a cutting tool that does not spin is moved against the material. It cuts bits away to make a round, tube-like shape. It is like a person shaping clay on a spinning wheel, but we use metal instead.

The “CNC” part of the name means Computer Numerical Control. This means a computer controls how the cutting tool moves. It is not a person turning handles on a manual lathe. A basic CNC lathe typically moves in two directions, which are called axes. The X-axis moves the tool toward or away from the center of the workpiece. This controls how thick the part is. The Z-axis moves the tool from side to side. This controls the length of the part. This simple two-axis system is the basic setup for a CNC lathe. It is a great machine for producing parts like shafts, pins, and rings.

The main job of any CNC lathe is CNC turning. The goal is to do turning operations. This is where the workpiece turns and the tool stays still. This machine is the new version of traditional lathes. It is automated to be very exact and fast. I have seen a good CNC lathe make hundreds of simple parts very, very accurately. This would take a very long time to do on a manual lathe.

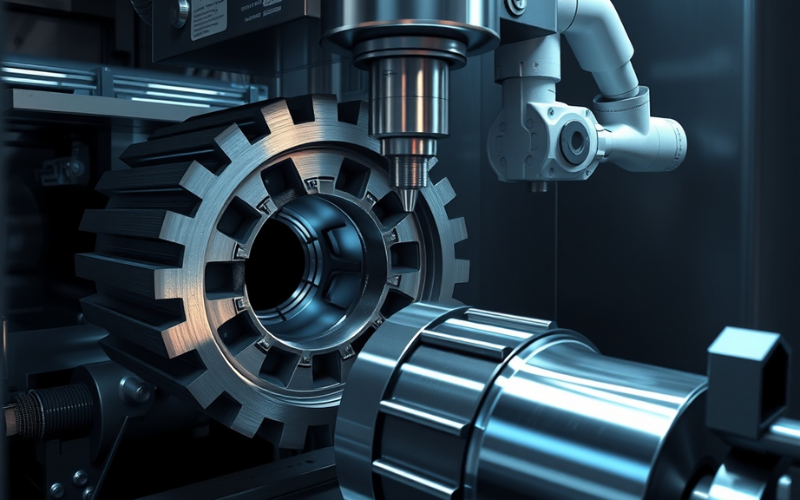

Now, we can talk about the CNC turning center. If a CNC lathe is a simple car, then a CNC turning center is like an SUV with all the extra features. Basically, a CNC turning center can do all the same jobs as a CNC lathe. It does CNC turning by spinning a workpiece and using a tool to cut it. But that’s where things start to be different. A CNC turning center is a machine that can do more and has more features.

The biggest difference between a CNC lathe and a CNC turning center is the extra things it can do. A CNC turning center almost always has a tool turret. A tool turret is like a spinning holder that has many different tools in it. This lets the machine change tools by itself in the middle of a job. The person running the machine does not have to stop it. Even better, these centers often have “live tooling.” This means some of the tools in the turret can spin on their own. This allows the machine to mill, drill, and make threads, not just turn.

These extra abilities are what change a simple CNC turning machine into a powerful CNC turning center. It is one piece of machinery that can do many kinds of CNC machining, not only CNC turning. The CNC turning center also might have another spindle or a Y-axis. These other features make it a powerful machine that can do many jobs at once.

This is a very important question. It gets to the heart of the CNC lathe vs CNC turning discussion. The simple answer is no. A basic, standard CNC lathe is not able to do milling operations. It is only built to do CNC turning. The spindle turns the workpiece. The cutting tool is held in a tool post and it does not spin. The tool can only move on its two axes to cut the part that is spinning.

To do a milling job, you need a cutting tool that spins. You also need the workpiece to be held still. Think about CNC milling with milling machines. The tool spins and the part moves. A standard CNC lathe does not have a way to make a tool spin in its holder. Its job is just to rotate a workpiece.

This is the main thing a CNC lathe cannot do. It is the main reason the CNC turning center was created. Machine shops needed a way to make more complex parts. These parts needed both turning and milling. They did not want to move the workpiece from one machine to another. Adding the power to perform milling on a lathe was a very big and important change for machinery.

Like I said before, a normal CNC lathe machine moves in two directions, called axes: the X-axis and the Z-axis. This two-axis system is simple. But it works very well for all kinds of turning operations.

This simple setup with the X and Z axes is all you need for making many kinds of turned parts. A simple CNC lathe is a very efficient machine for these jobs. But this is also its main drawback. The machine cannot make shapes on the front or side of a part. Those shapes need a tool to move in a different direction. An example is drilling a hole on the side of a tube. That is when you need more axes.

A CNC turning center is a more complicated machine. This is because it uses newer, more complex technology so it can do more types of jobs. The complexity begins when you add more axes. Many CNC turning centers have a C-axis. This lets the main spindle be turned to an exact spot and held there. So, instead of just spinning, the spindle can rotate to a specific spot and stay put.

When you have a C-axis and also live tooling, you can suddenly mill and drill. You can do this on the front or around the outside of the workpiece. Some very advanced machinery will also add a Y-axis. The Y-axis lets the tool turret move up and down. This is at a right angle to the X-axis. This lets you do many new things. You can make very complex parts that have holes or slots that are not in the center. It basically gives the turning machine some of the abilities of a CNC milling machine.

These multi-axis abilities, plus features like a second spindle, are what make the CNC turning center a machine that can truly do many jobs at once. A second spindle can grab the part from the main spindle to work on its other side. All of these moving parts need a more advanced CNC control. They also need more complex programs. This makes the machining process on this machine more difficult than on a simple CNC lathe.

I have talked about “live tooling” a few times, so let’s look at what that means. Live tooling is a very important feature for CNC turning. On a regular CNC lathe, all the tools in the tool turret do not move on their own. They cannot spin. A live tooling system lets certain tools in the turret, like an end mill or a drill, get power and spin by themselves, separate from the main spindle.

So, how does it work? To use a live tool, the machine’s main spindle can be stopped. The spindle holding the workpiece can be locked in one position using the C-axis. Then, the live tool in the turret will start spinning. It will do a drilling or milling job on the workpiece, which is not moving. This is how you can drill a hole in the side of a shaft. It is also how you can mill a flat area on a round part using a CNC turning center.

This ability is what makes lathes and turning centers different. The power to do milling and drilling on the same machine where the part is turned is very good at saving time and effort. It means many complex parts can be completed in one setup. This means less time moving parts around. It also makes the parts more accurate and helps you get more work done. For today’s aerospace and medical parts, live tooling is something you almost always need.

With all the great things a CNC turning center can do, you may ask why anyone would still buy a simple CNC lathe. The answer is about two things: how simple the machine is and how much it costs. A CNC lathe is a simpler machine that costs less money.

You should pick a CNC lathe when your work is mostly making simple parts. These parts should only need turning operations. If you are making thousands of pins, bushings, or simple shafts, a CNC lathe is the best machine for that job. It is quicker to set up. It is easier to program. It also costs less to buy and take care of. You do not need to pay for milling capability if you are never going to use it.

But, if you need to make complex parts that need both turning and milling work, a CNC turning center is the right choice. It costs more to buy at first. But the ability to finish a part in one step on a single machine saves a lot of time and money over time. You do not have to move a workpiece from a lathe to a mill. Moving parts is a big reason for mistakes and wasted time in many machine shops.

Let’s put the big benefits of each machine tool in a simple table. This can help you see the CNC lathe vs CNC turning center comparison quickly.

| Fonctionnalité | Tour CNC | Centre de tournage CNC |

|---|---|---|

| Emploi principal | CNC Turning only | CNC Turning, milling, drilling, etc. |

| How Complex It Is | Simple (usually 2 axes: X, Z) | Complex (multi-axis: 3, 4, 5, or more) |

| Outillage | Static cutting tool | Tool turret with live tooling options |

| Meilleur pour | High numbers of simple parts | Complex parts needing many steps |

| Coût | Lower price to buy | Higher price to buy |

| How Much It Can Make | High for simple turned parts | High for complex parts (fewer setups) |

| How Many Jobs It Can Do | Faible | Très élevé |

As you can see, the choice is not about which machine is “better” in general. It is about which machine is better for the work you do. Both the CNC lathe and turning center are great tools in modern CNC machining. The ability of a CNC turning center to do many different jobs is great for complex parts. But the simple, focused power of a CNC lathe is perfect for easier jobs.

It is surprising to see how much things have changed. The basic manual lathe has been around for hundreds of years. For a long time, making a part needed a person with a lot of skill to stand at the machine. That person had to turn handles and measure every cut with great care. This was a slow process. How good the part was depended completely on the person making it. Compared to manual lathes, today’s CNC technology is like something from the future.

The creation of Computer Numerical Control was the big step up. It let us automate the machining process. By writing a program, we could tell the machine just how to move the tool. This let us create a perfect part, time after time. This made parts very exact and correct for making things. The first CNC lathe machines were simple two-axis machines, but they were a huge change.

The CNC turning center is the next step in this change. Engineers saw that by adding more axes and powered tools, they could put more processes into a single machine. This idea of putting more jobs into one piece of machinery—like adding milling to a turning machine—is still happening today with even more advanced multi-axis centers. This change is all about working faster and making it possible to create even more complex parts.

So, we are back to our main question. We have learned that the main difference between a CNC lathe and a CNC turning center is what the machine can do. A CNC lathe turns. A CNC turning center turns, mills, drills, and does more.

When you are choosing for your workshop, look at the kinds of parts you need to make.

I hope this has made things clear. Knowing the difference between these two powerful pieces of machinery is very important for anyone who makes things, from the people who run the machines to the owners of the shops. They are both wonderful tools. Picking the right one will help you make better parts, in less time, and with less effort.