Laissez Istar vous aider à démarrer votre projet avec notre expérience et notre savoir-faire !

Téléchargez vos fichiers de conception et vos exigences de production et nous vous répondrons dans les 30 minutes !

It’s easy for people to confuse polypropylene and polyethylene, and I understand why. At first glance, they appear to be very much alike. But there is a big difference between polyethylene and polypropylene. Understanding this difference can help you avoid problems. This is true if you are creating a new item or even just picking a food container. In this post, I will explain what I know about these two wonderful materials. We will explore what they are made of and what they are good at. I will also help you learn how to choose the right one for what you need to do. This is a look into the world of polymers that I believe you will find very interesting.

They are like family members in the plastic world, but they have very different qualities. The main difference between polyethylene and polypropylene is found in a few important things. These are how they handle heat, how stiff they are, and their density.

You can think of polyethylene (PE) as the one that is flexible and simple to work with. It is good in cold weather and is very long-lasting. In contrast, polypropylene (PP) is the stronger, stiffer one that can handle high heat. Polypropylene has a higher melting point. This makes it perfect for items that need to be cleaned with heat. Examples include medical tools or food containers you can put in the microwave. So, even though polyethylene and polypropylene are two very common plastics, their big differences in physical properties mean they are used for a very different range of applications.

I get asked this question many times. The easy answer is both yes and no. Both polypropylene and polyethylene are part of the same group of polymers. This group is called polyolefins. They are also both a type of thermoplastic. This is just a simple way of saying you can melt them and shape them into something new very easily. This is the reason they are used so much in making things. It is also why they can be recyclable.

The word ‘poly’ in their names means ‘many’. Both plastics are made of long chains. These chains are formed by small, repeating parts called monomers. For polyethylene, the monomer is ethylene. And for polypropylene, the monomer is propylene. So, they have the same family name (polyolefin) and an important quality (thermoplastic). But they are built from different basic parts. This is what makes them special in their own ways. It is similar to two brothers in one family. They are related but have different talents and ways of being.

When I am looking for a material that gives both flexibility and durability, I often pick polyethylene first. This useful material comes in a few different types. Each type is good at something different. The two types you will see most often are low-density polyethylene (LDPE) and high-density polyethylene (HDPE). LDPE is very bendy. It is used to make things like plastic bags and thin plastic sheets. HDPE is stiffer. It is great for making milk jugs, pipes, and toys.

One of the main characteristics of polyethylene is its amazing impact resistance. It is also very tough, even when it is cold. It will not break easily if you drop it. That is why it is a popular choice for products that might be handled roughly. Polyethylene is also very good at stopping electricity from passing through. But, it can be damaged by the sun’s UV rays. So, if you use it outside, it needs special additions to keep it safe. This useful polymer is a very reliable material in the world of plastic.

Next, we will discuss polypropylene. If I needed to explain PP with just a few words, I would say it is strong, stiff, and has good heat resistance. One of the most special characteristics of polypropylene is its great fatigue resistance. This means you can bend it over and over again, and it will not break. Have you seen a container with a special kind of hinge, like the lid on a ketchup bottle? That part is almost always made from polypropylene.

Polypropylene is also not very heavy. It also has a strong resistance to chemicals and different kinds of solvents. This makes polypropylene a great pick for automotive parts, tools used in labs, and containers you can use again. Different from polyethylene, PP can be made partly see-through, which is called translucent, but it cannot be made totally clear. It is a wonderful and useful polymer. It is often used for jobs that require a material to work well in higher temperatures. Polypropylene is also famous for being strong.

From what I have seen, choosing between polyethylene vs polypropylene for packaging is all about what you need to keep safe. There is not just one correct answer. Both polyethylene and polypropylene are very commonly used in packaging. But they are used for different reasons. Polyethylene, mainly LDPE and LLDPE, is the top choice for plastic films and bags. This is because it is very flexible and does not tear easily. For example, think about grocery bags, shrink wrap, and bubble wrap. The PE gives very good protection from water and moisture.

In contrast, the stiffness and higher melting point of polypropylene make it perfect for hard packaging materials. This means things like yogurt cups, containers for margarine, and medicine bottles. Because polypropylene works well in higher temperatures, it is the obvious choice for food packaging. This is for food that you need to heat in a microwave or for containers that will hold hot liquids. So, when you are comparing polypropylene and PE for packaging, you must decide if you need something flexible or something that can handle the heat.

If you want to truly understand the differences between polypropylene and its relative polyethylene, you need to look at their molecular structure. Both of them are made of long chains with repeating parts. But that is where they stop being similar. Polyethylene is created from the ethylene monomer. This is a very simple type of molecule. How these chains are put together decides the kind of polyethylene it becomes. In HDPE, the chains are long and have no branches. This lets them pack very close to each other. This is the reason HDPE is more rigid. In LDPE, the chains have branches on them. These branches stop the chains from getting too close. This makes the plastic more flexible.

Polypropylene is made from a monomer that is a little more complex. It is called propylene. This monomer has an extra part called a methyl group. Where this group is placed on the polymer chain makes a very big difference in how the material behaves. This change in the molecular design is what makes polypropylene stronger and stiffer. It also gives it a higher melting point when compared to polyethylene materials. It is a tiny detail at a very small level, but it causes big changes in how the material works in everyday use.

If you practice a little, you can learn to see the difference. You can tell apart items made of polypropylene and items made of polyethylene. Items made from Polyethylene often have a waxy feel when you touch them. Think about a milk jug, which is HDPE. Or think about a bendy food storage bag, which is LDPE. Plastic bags are a perfect example of low-density polyethylene. They can bend and stretch before they rip.

Things made of polypropylene are usually stiffer. They often have a surface that is smoother and feels more slippery. If you own a food container that you can use again and it says it is safe for the microwave, it is very likely made of PP. Another great way to tell is the “living hinge” I talked about before. These are the thin plastic parts that can bend many times without breaking. That is a special feature of polypropylene. The pp and pe plastics are all around us. After you know what to look for, you will begin to notice these different uses everywhere.

When we talk about handling difficult situations, polypropylene is often the better choice. One of the biggest significant differences is its excellent heat resistance. Polypropylene can work in temperatures as high as 160°C (320°F). But HDPE begins to get soft at about 130°C (266°F). This resistance to high temperatures makes PP a good material for medical parts. These parts need to be cleaned in a machine called an autoclave.

Polypropylene also has a somewhat better high resistance to chemicals and solvents. Both plastics are pretty resistant. However, polypropylene is not as easily harmed by strong organic solvents. But polyethylene has a special advantage. It works much better in cold weather. Polypropylene can get fragile and break easily when it is freezing. But PE stays tough and bendy. This makes it a better pick for uses in very cold places.

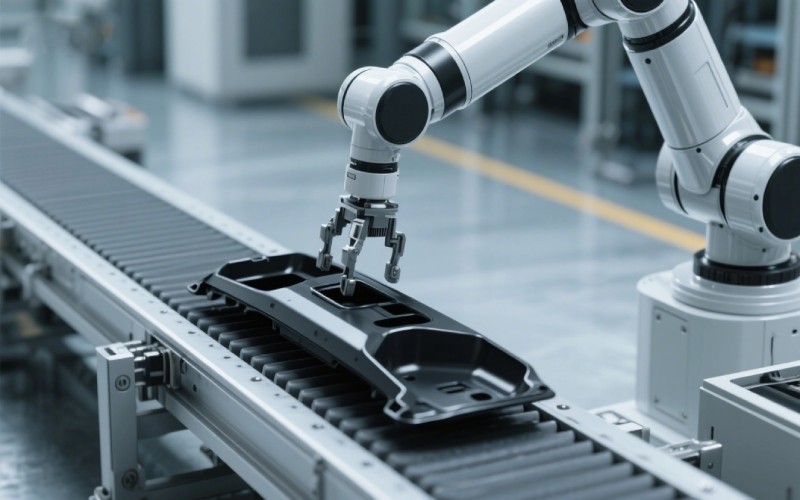

I have spent many, many hours in factories. I have watched these materials get formed into products. Both pp and pe are part of the thermoplastic polymer group. This means you can melt them and shape them without a problem. The most popular way to shape them both is called injection molding. During this process, small plastic beads are melted. Then, they are pushed with high pressure into a mold. This is the way we make all sorts of things, from car bumpers to the caps on bottles.

There is another common method called extrusion. It is especially used for polyethylene. It is used to create films, flat sheets, and pipes. The melted plastic is pushed through a special opening. This creates a long, continuous shape. Because polyethylene and polypropylene are very easy to use in processes like injection, they are very cost-effective. This makes them great materials for making a wide range of consumer goods and automotive parts. The fact that you can make these plastics in many ways is a main reason why they are used so much.

Yes, they can. This is one of the greatest things about these materials. It is true that polyethylene can be recycled, and polypropylene can be recycled too. If you check the bottom of a plastic container, you will find a number inside of a triangle. This is called the resin identification code. It lets you know what kind of plastic you have.

Here is a simple table:

| Code de recyclage | Plastic Type | Common Items |

|---|---|---|

| #2 | PEHD (polyéthylène haute densité) | Milk jugs, shampoo bottles |

| #4 | LDPE (Low-Density Polyethylene) | Plastic bags, squeezable bottles |

| #5 | PP (Polypropylène) | Yogurt containers, bottle caps |

Many recycling programs that pick up from your home will take #2 HDPE and #5 PP containers. LDPE (#4) can be a little more difficult. You usually need to take plastic bags back to special bins at the grocery store. So, even though both plastics are recyclable, it is a good idea to ask your local recycling service what they will take. When you do this, you help us reuse these useful thermoplastic materials in the best way.

Even after many years, I still think the world of polymers is very interesting. Here is a list of the key things to keep in mind about polypropylene vs. polyethylene: