Laissez Istar vous aider à démarrer votre projet avec notre expérience et notre savoir-faire !

Téléchargez vos fichiers de conception et vos exigences de production et nous vous répondrons dans les 30 minutes !

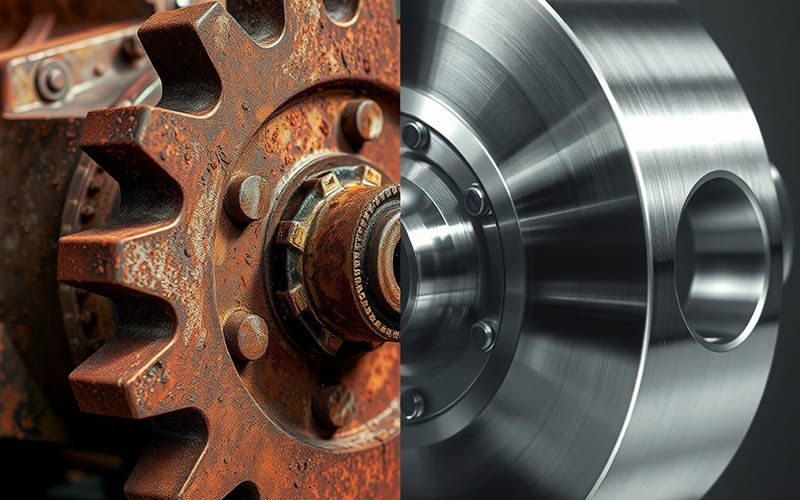

Knowing about corrosion is not just for engineers. It’s for anyone who wants the things they build to last a long time. This is important because corrosion costs us billions of dollars each year.

This article is your easy guide to the world of the best corrosion-resistant materials. I will explain this tricky topic using simple words. You will learn what corrosion is and how some materials can fight it. You will also learn how to pick the best material for your work. Reading this will save you time, money, and a lot of future problems.

In simple terms, corrosion is the natural way a finished metal falls apart. It’s a kind of degradation. The metal tries to change back to its natural form, like an oxide. We usually call this process rust when we see it on iron or steel.

You should worry about corrosion because it is all around us, and it costs a lot of money. It makes bridges weaker. It damages pipes and ruins cars. This is an electrochemical process. It can cause very bad safety problems. Knowing how to stop corrosion is important for building things that are safe and will last. When you pick a corrosion-resistant material at the start, you make sure your project will have a long life and be strong. This fight against corrosion is a fight that never stops.

So, how does a corrosion-resistant material do its job? It is not magic. It is just science. Most of these materials work because they make a very thin, invisible shield on their outside surface. When the metal touches air and water, its surface creates a shield to protect itself. This shield is called a passive film or an oxide layer. This is a type of controlled oxidation.

This protective layer is the most important part. It stops water and oxygen from getting to the underlying metal. This stops the corrosion from even starting. If this layer gets a scratch, the corrosion-resistant material is able to fix itself. The open metal surface will mix with the oxygen in the air again. This will form a protective new oxide layer. The power to heal itself is what makes a corrosion-resistant material so good at stopping degradation.

When people ask me for the best corrosion-resistant materials, I say there is not just one right answer. The very best corrosion-resistant material changes based on the job. But, there are a few main choices that I use over and over. The most common corrosion-resistant materials include stainless steel, aluminum, and copper alloys. Each of these has its own good points and bad points.

To help make it simple, I have made an easy table. This will let you compare these common corrosion-resistant choices. You can look at a few of their key material properties. When you look at it, think about what is most important for your project. Is it how strong it is? How much it costs? Or how it looks? This is the first step in choosing the right material.

| Matériau | Main Feature | Domaines d'utilisation | How Well It Resists Corrosion |

|---|---|---|---|

| Acier inoxydable | Strong & can be used in many ways | Kitchens, doctor’s tools, buildings | Très élevé |

| Aluminium | Lightweight & pretty strong | Airplanes, window frames, cars | Haut |

| Copper & its Alloys | Carries electricity, looks nice | Wires, pipes, roofs, statues | Haut |

I get this question a lot. Is stainless steel the perfect corrosion-resistant choice? It is one of the most used, for sure. What makes stainless steel “stainless” is an alloy ingredient called chromium. When this special alloy is exposed to water or air, the chromium oxidizes. This creates a tough, unseen protective layer of chromium oxide. This chromium oxide film is what gives stainless steel its excellent corrosion resistance.

But not all stainless steel is the same. There are many different grades of stainless steel. Each one has a different amount of chromium and other things like nickel. For example, duplex stainless steel is very strong and fights corrosion very well. This makes it great for hard jobs. For things we use every day, like kitchen sinks, a normal grade of stainless steel is fine. So, it might not be the very best corrosion-resistant solution for every job. But stainless steel is a wonderful and useful corrosion-resistant material. The trick is to pick the right grade of stainless.

Let’s talk about aluminum. I feel that people don’t realize how good it is. When I think of aluminum, I think of airplanes and space travel, or aerospace. It is the top choice for airplanes for two main reasons. First, it is very strong for how light it is. This is its strength-to-weight ratio. Second, it has amazing corrosion resistance. Just like stainless steel, aluminum protects itself from corrosion in a special way.

When aluminum touches the air, right away, it makes a hard, thin oxide layer on the surface. This layer is made of aluminum oxide. This protective layer holds on very tight to the aluminum. It stops more corrosion from happening. This is why aluminum window frames can last for many decades with no rust. There are also many aluminum alloys. These are made by mixing aluminum with other things to make its mechanical properties better, like giving it high strength and toughness. These aluminum alloys are used in everything from airplanes to drink cans. They all get the benefit of being a great corrosion-resistant material.

Now, let’s talk about copper. It is a nice-looking metal that has been used for a long time. You may have seen it on old buildings, where it has turned a nice green color. That green color is called a patina. It is really a layer that keeps the copper safe from more corrosion. This natural protection makes copper a very long-lasting and corrosion-resistant material for things like roofs and gutters.

Copper is also used to make other helpful alloys. The most well-known are brass and bronze. Brass is a mix of copper and zinc. It is often used for pipes in bathrooms and for musical instruments. It has good resistance to corrosion that comes from water. Using a copper alloy is a smart choice when you need a corrosion-resistant part that also needs to look good. The special color of copper and brass can make any project look special.

Stainless steel, aluminum, and copper are the main three. But there are other options. Here are some more examples of corrosion-resistant materials that I have used. For the very hard jobs, especially in aerospace applications, there is titanium. It is very strong and can handle very hot temperatures. But, it costs a lot of money. It is a top-level corrosion-resistant material.

Next is galvanized steel. This is a smart way to give normal carbon steel some corrosion protection. It is done by putting a thin layer of zinc on the steel surface. The zinc acts as a shield that gets damaged first. It will corrode before the steel does, which keeps the steel safe. We see it used in things like street signs. Other materials like nickel alloys are used in very harsh chemical factories. This is because they can handle high temperatures and acid. These materials are designed to withstand very bad conditions where other metals would be destroyed.

Sometimes, the best answer is not a special metal mix, but an easy coating. A coating is just a shield that you put on a metal surface to keep it safe. You can think of it like a raincoat. It keeps the bad things, like water and oxygen, away from the metal. The most common type of coating is paint. It gives good protection against corrosion for some time. But, it can get chipped or peel off. This leaves the underlying metal open to damage.

For harder jobs, we use stronger coatings. These can be made from a tough polymer resin or even thin layers of a different metal. The main purpose of any coating is to stop air and water from reaching the underlying steel or iron. It puts up a wall to block the electrochemical reaction of corrosion. A good coating is a cheap way to make a less resistant metal last for many more years.

This is a very important question. Choosing the right corrosion-resistant material is a big choice. I have seen projects go wrong because the wrong material due to its surroundings was picked. The material of choice will depend on several factors. First, you must think about what the area is like. Will it be inside or outside? Will it be around a lot of water? Will it be near the ocean?

Next, you have to think about the mechanical properties you need. Do you need something with high strength? Does it need to be able to bend (ductility)? Or is its toughness more important? Last, you must think about the cost and how easy it is to build with. Some materials cost a lot or are hard to work with. The trick is to find the right mix of good performance and low cost. This will help you pick the right corrosion-resistant material. My advice is to make a list of what you need first. Then, find the corrosion-resistant material that meets most of your needs.

I want to talk for a minute about marine environments. They are one of the most difficult places for any metal. The salt in the ocean water makes it a very corrosive environment. Saltwater makes the electrochemical process of corrosion happen much, much faster. This can make a normal metal break down very quickly. That is why the choice of material is so vital for boats, docks, and oil rigs in the sea.

In salty places, you also must think about galvanic corrosion. This happens when two different kinds of metals touch each other in saltwater. One metal will start to corrode very fast to save the other one. To stop this, we use special stainless steel alloys that are made to fight saltwater. Materials like titanium and some plastics are also used. If your project is near the ocean, you have to pick a corrosion-resistant material made to deal with that tough, salty problem. This will stop localized corrosion, which can be very unsafe.

Here are the most important ideas to remember from what we talked about. Keep these points in mind. You will be on your way to stopping corrosion before it starts.