Laissez Istar vous aider à démarrer votre projet avec notre expérience et notre savoir-faire !

Téléchargez vos fichiers de conception et vos exigences de production et nous vous répondrons dans les 30 minutes !

Have you ever seen a metal part with small, exact cuts and thought about how they made it? It was probably cut with a special manufacturing process called Wire Electrical Discharge Machining. In this article, I am going to explain this wonderful technology. We will look at how a wire EDM machine uses electrical discharges to make parts that are very, very exact. You will learn why this way of cutting is often the best for hard jobs. You will also see how it has changed modern EDM manufacturing. If you have to make exact parts from strong metals, you should read this.

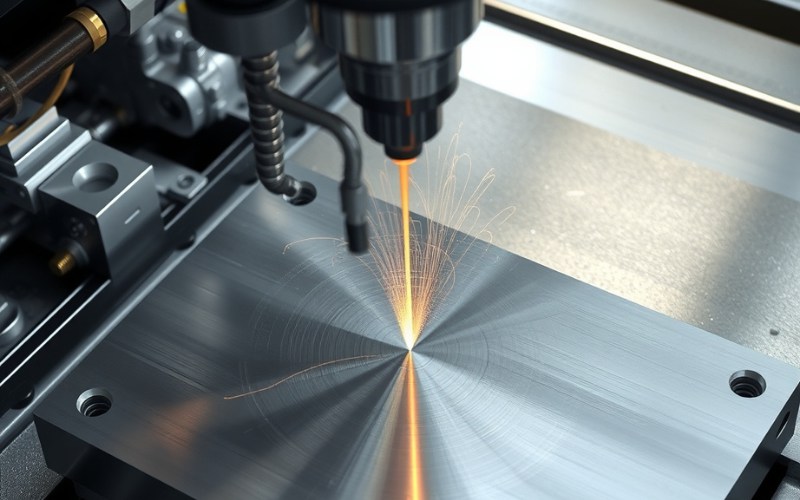

When I first learned about electrical discharge machining, it sounded hard to understand. But the main idea is easy. Think about cutting a block of hard cheese with a very thin wire. Now, think about that wire having electricity in it. This wire can cut right through hard steel, but it never touches the steel. That is the simple idea of how a wire EDM machine works. It is a machining process where the tool does not touch the part. It uses electrical discharges (sparks) to cut or give shape to a metal workpiece.

The machine looks a little like a bandsaw. But it does not have a saw blade. Instead, it uses a very thin wire electrode. This wire is often made of brass and is as thin as a person’s hair. The wire EDM machine uses this wire to cut or shape any material that electricity can pass through. Because the wire does not physically touch the workpiece, the wire doesn’t push on the part. This means we can make very fine and complex shapes. We do not have to worry that the part might bend or break. This is a big plus compared to older ways of cutting metal. The wire EDM machine is the right tool for jobs that need to be very exact.

The amazing part of the EDM process happens at a very small level. The process starts by putting a workpiece in a tank of dielectric fluid. The workpiece must be made of a conductive material. The fluid is usually special water called deionized water. This fluid stops electricity from flowing. But when the power gets high enough, it lets the electricity pass. A thin wire electrode is placed very near the workpiece. They do not touch. The small space between the wire and the workpiece is called the “spark gap.”

When the machine gets power from the power supply, both the wire and workpiece become electrically charged. When they are close enough, the dielectric fluid can no longer block the electricity. Then, a strong, managed spark shoots across the small space. This discharge is very, very hot. For a tiny moment, it is hotter than the sun. This great heat melts a tiny piece of the metal workpiece and turns it into a gas. The flowing dielectric fluid then washes this little piece away. This cycle of making electrical discharges happens thousands of times every second. This slowly wears away the material to make the desired shape. The wire EDM process is a very exact way to remove material.

To see how it all comes together, let’s look at the components of a wire EDM machine. I have seen many of these machines. They all have the same main parts that work with each other to do the cutting process. Each part has a very important job.

A wire EDM machine is a machine with many parts. Here are its main ones:

| Composant | Ce qu'il fait |

|---|---|

| Contrôleur CNC | This is like the computer brain for the wire EDM machine. The CNC (Computer Numerical Control) reads a computer file of the design. Then it tells the wire just where to go. |

| Alimentation électrique | This gives the power needed to make the spark. It controls when each discharge happens and how strong it is. |

| Wire Electrode | This is the cutting tool. It is a thin brass wire that is always moving from a big roll, called a spool. It goes through the workpiece. |

| Work Table | This holds the workpiece very still during the machining process. |

| Dielectric System | This system holds the dielectric fluid (deionized water). It also moves it around and keeps it clean. This fluid is needed for the electrical discharge machining process. |

These parts working together help the wire EDM machine follow a very exact path. They erode the workpiece to get the desired shape. The CNC control makes it possible to create very complex shapes. You could not make these shapes with other machining methods. The roll of wire is used to make sure there is always a new, clean electrode for a good cut.

People often ask me, “Why use wire EDM? You could use a laser or an old-style mill.” The reason has to do with being exact, how hard the material is, and how detailed the part is. Conventional machining uses a hard cutting tool. This tool cuts off little bits of material. This puts pressure on the part. It can bend or change the shape of thin parts. Wire cut EDM does not touch the part. This means there is no pressure or harm to the workpiece.

What about laser cutting? Laser is quick, but it can leave an area changed by heat. This changes how the metal acts near the cut. A wire EDM machine makes a much smoother surface finish. There is no area changed by heat. Wire EDM cutting is also able to cut very thick materials. The walls of the cut are perfectly straight. Lasers have a hard time doing this. EDM offers many good things, especially when you work with hard materials or parts that need tight tolerances. It is a special and strong machining process.

There is one important rule for wire EDM. The material must let electricity pass through it. If a material can conduct electricity, a wire EDM machine can likely cut it. This is because the EDM process depends on an electrical discharge between the electrode and the workpiece. This makes the wire EDM machine able to be used in many different ways.

Being able to cut any conductive material is a big plus. It works very well on common metals like steel, aluminum, and copper. But it is especially good for cutting hard materials. These materials are very tough to cut with other tools. This group includes materials like titanium, tungsten carbide, and special strong metals used for airplanes and spacecraft in aerospace. Because EDM can handle these tough materials so easily, it has become very important for many industries that use new technology. How hard the material is does not change the cutting speed as much as it does in traditional machining.

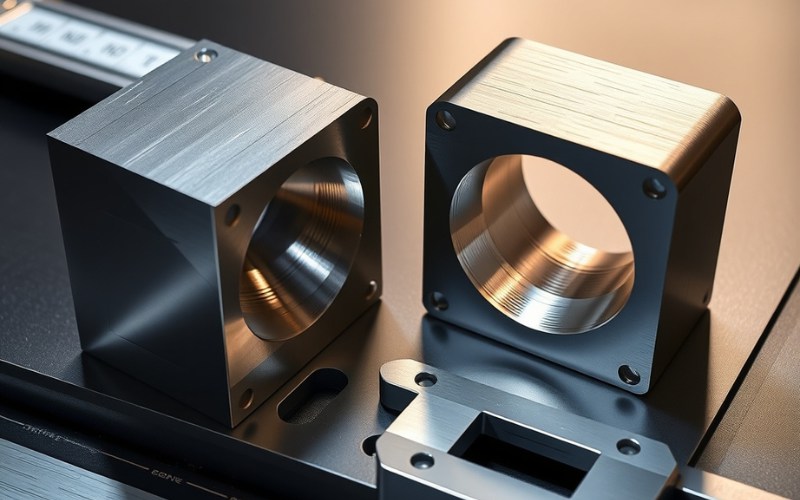

Yes, for sure. From what I have seen, this is a top reason why people pick wire EDM services. Tolerance means how close the final part is to the size it was planned to be. Wire EDM is well-known for being able to make parts with very tight tolerances. This is often within a few ten-thousandths of an inch. It is very hard, or even impossible, to get this level of exactness with many other ways of making things.

There are two big reasons EDM can achieve this kind of accuracy. First, like I said before, the tool does not push on the part. The wire never touches the workpiece. So there is no pushing or bending. There are also no shakes that could make a mistake. Second, a CNC computer controls the whole wire EDM process. The computer moves the wire electrode along a very exact line. This makes a perfect cut each time. This makes it perfect for making parts where being exact is very important, like in medical tools or aerospace parts.

You can find parts machined by wire EDM in a lot of different fields. It is used most in places that need very exact and detailed designs. There are many, many applications of wire EDM. When I go to different factories, I see it being used all over the place. It is an important technology. It helps us make many of the things we use today.

Here are a few wire EDM uses:

The CNC controller is the most important part of any modern wire EDM machine. CNC stands for Computer Numerical Control. It is what makes the whole machining process run by itself. Without CNC, we could never make the detailed shapes or be as exact as we are with wire EDM. It is a very important piece of the wire-cut EDM system.

The CNC system works by looking at a computer design file, also called a CAD file. This file shows the exact line the wire electrode must follow. The CNC then changes these directions into very exact movements of the work table and the wire guides. The wire can move in many directions. This lets it cut fancy patterns, angles, and curves. The person running the machine just has to put the workpiece in place and start the program. Then, the CNC machine takes over and can control the process. Because it works by itself, it makes sure every single part is exactly the same. This is very important for EDM manufacturing and other manufacturing services including Usinage CNC.

Yes, wire EDM is only one kind of electrical discharge machining. The same main idea of using a spark to wear away metal is also used in other kinds of EDM. The two other main kinds I see are sinker EDM and hole EDM. Each one is made to do a certain kind of job.

Sinker EDM is sometimes called ram EDM. It does not use a wire. Instead, it uses an electrode that has a special shape. This tool electrode is often made of graphite or copper. This electrode is lowered into the workpiece. Then, sparks jump from the whole surface of the electrode. This erosion makes a hollow space in the workpiece. The space is the exact opposite shape of the electrode. It is great for making molds that are used to form plastic parts. Hole EDM, also called a “spark driller,” is a special process that uses a spinning tube as the electrode. This helps it drill tiny, deep holes very fast in hard materials. People often use these holes to get started. The wire EDM machine can then thread its thin wire through the hole. EDM is also called wire burning or wire erosion.

After reading all this, you may be thinking, “This sounds good, but I don’t have enough money for a wire EDM machine!” The good news is that you do not need to buy one. There are many great businesses that provide wire EDM services. This lets you use this great technology without spending a lot of money on a machine. This is how many people get EDM work done.

To begin, you will need a computer design of your part. This is usually a CAD file. You can send this file to a few companies that offer EDM services. They will tell you how much it will cost. Try to find a company that has worked with businesses like yours before, like in aerospace, medical, or automotive. They can look at your design. Then they can tell you if wire EDM work is the best machining process for what you need. A good manufacturing services provider will work with you. They will make sure your parts are made exactly the way you want them. Wire EDM can also be used with other methods, including CNC machining, to make a complete part.