Biarkan Istar membantu Anda memulai proyek Anda dengan pengalaman dan pengetahuan kami!

Unggah file desain dan persyaratan produksi Anda dan kami akan menghubungi Anda dalam waktu 30 menit!

Have you ever held a tool and felt the crisscross design on the handle? That design helps you get a firm hold. That, my friend, is called knurling. I have worked in the world of making things for a long time. I can tell you that knurling is a simple but very helpful method. Knurling is a way of making things that puts a textured design on the outside of a part. This article is your full guide to learning about knurling. We will look at how it is done, the different kinds, and why it is so key in making things we use every day better and safer.

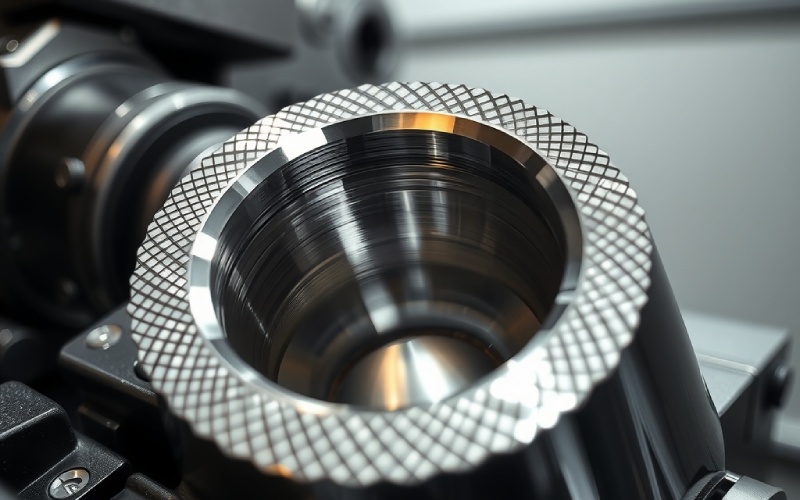

I remember the first time I saw knurling being done. It was amazing to watch. A smooth piece of metal was changed into a piece with a texture in just a few seconds. Knurling is a machining process. It uses a special tool to press a design onto a part. You can think of it like using a stamp on metal. The method does not usually cut away material. Instead, it moves the material around. This creates a design of raised lines. This is what gives the outside its grip.

The way knurling works is very simple. A knurling tool has one or more hard wheels that have the design on them. This tool is pressed against a part that is spinning. The pressure from the knurling wheel changes the shape of the part’s surface. This creates the design. It is a process done without heat. This makes it a fast and good way to add a useful and nice-looking feature to a part. The knurled surface has raised spots that give you a better hold. It can also make a part look more complete and well-made.

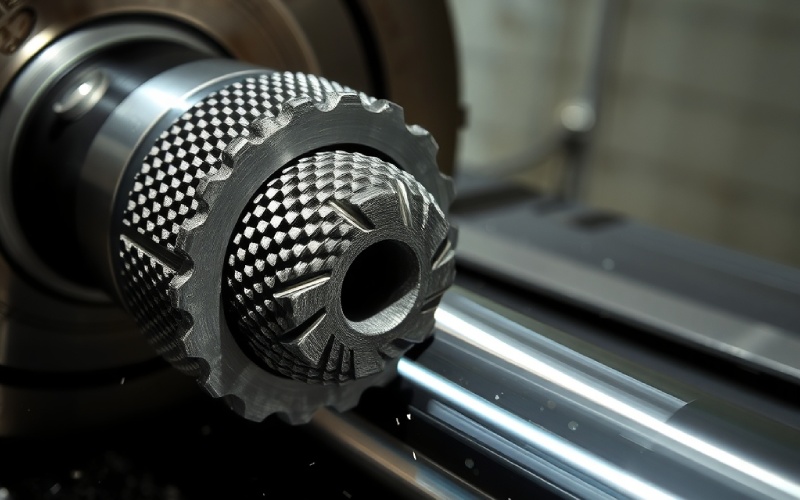

From what I have seen, most knurling is done on a lathe. A lathe is a machine that spins a part around its center. The knurling process on a machine is not hard to understand. First, the part is held tightly in the lathe. Next, the knurling tool is put onto the tool holder of the lathe. The machine is started, and the part begins to spin.

The real change happens when the knurling tool is slowly moved to touch the spinning part. The knurling wheel is pushed against the outside of the part. Then, the design gets copied onto it. The person running the machine carefully manages the pressure and the speed. This is to make sure the knurling design is clear and even. For a diamond knurling design, two wheels are used. Their teeth are angled in opposite ways to make the crisscross look. This machining process is how the textured surface is made, which is so helpful in many ways.

Through the years, I have seen lots of different knurling designs. Each one has its own special use. The most common kinds of knurling designs are straight, diagonal, and diamond.

| Desain | What it looks like | Where it is often used |

|---|---|---|

| Lurus | Lines next to each other | Tool handles, knobs |

| Diagonal | Slanted lines | For decoration, some grip uses |

| Berlian | Crisscross lines that make diamonds | Hand tools, anything that needs a very firm hold |

Yes, there are! Just like there are different designs, there are also different kinds of knurl tool holders to make them. The holder is what keeps the knurling wheel or wheels in place. It holds them steady as they are pushed against the part. Some holders are made to hold just one knurling wheel. These are for making straight or diagonal designs.

For diamond knurling, you will often find holders that can hold two or even three knurling wheels. There are also different kinds of knurl tool holders made for certain machines, like a lathe or a milling machine. The kind of holder you pick depends on the machine you are using. It also depends on the knurling design you want to make. It is important to pick the right knurling tool and holder for the task to get a clean and even result.

I have always been a big fan of knurling. I like it because it has many good points. The clearest good thing about knurling is the better grip it gives you. That textured outside makes it much easier and safer to hold tools and other items. This is very true when things are wet or oily.

But the good things about knurling are more than just a better grip. Knurling can also be used for:

I really like knurling, but I must say it is not always the best choice. There are a few downsides to knurling to think about. One possible problem is that the knurling process can add stress to the part. In some situations, this could make the surface a little bit weaker.

Another point to remember is that knurling makes the surface rough. This might not be what you want for every use. If you need a very smooth and shiny surface, then knurling is not the right choice. It is also good to know that knurling might not work well on all kinds of materials. Materials that break easily can crack or get bent out of shape from the pressure of the knurling tool.

If you look around you, you will begin to see knurling in many places. I have seen it used in so many different fields and for so many different things. Knurling is often used on tool handles. This is to give the person using it a firm hold. You will also see it on the knobs and dials of stereos and other electronics. It makes them easier to turn.

Other common uses for knurling are:

The main tool in the knurling process is the knurling tool. This is the hand tool or machine tool that makes the design on the outside of the part. A knurling tool is usually made of one or more hard steel wheels. These wheels have the design you want on their edge.

These knurling wheels are placed in a holder that lets them spin freely. When the knurling tool is pushed against the spinning part, the knurling wheel moves along the surface. This presses the design into the material. There are different kinds of knurling tools you can get. These include hand knurling tools for small tasks and stronger tools for use in a lathe or milling machine. The tool you pick depends on the type of knurling job and what you want the result to be.

In all my years of work, I have seen knurling done on many kinds of materials. Knurling is most often done on softer metals. These metals can be easily shaped without breaking. Some of the most common materials for knurling are:

These materials are soft enough for the knurling tool to make a clear design. It can be done without hurting the part or wearing out the tool too much. You can do knurling on harder materials, but it is more difficult. It might need a different knurling method, like cut knurling. Knurling can also be done on some types of plastic.

The cost of knurling can change based on a few things. If you are doing just one project, the cost will be different than setting up to make a large number of parts. The difficulty of the knurling design can also change the price. For example, diamond knurling can sometimes cost more than straight knurling.

In general, the cost of knurling is pretty low when you compare it to other ways of shaping metal. Buying a good knurling tool does not cost a lot of money. The process itself is also very fast and gets the job done well. To find out the exact price, it is always best to ask for a cost estimate from a machine shop that does knurling work. Some places even have prices based on the length for certain designs like diamond knurling.