Biarkan Istar membantu Anda memulai proyek Anda dengan pengalaman dan pengetahuan kami!

Unggah file desain dan persyaratan produksi Anda dan kami akan menghubungi Anda dalam waktu 30 menit!

You can find polypropylene in many places. It is in your car and in your food containers. In this article, I will explain what makes polypropylene so great. We will look at what it is and how it is made. We will also see why it is used in so many things you use each day. If you have ever wanted to know more about the plastics in your life, this is the right place for you. Let’s start and learn about the world of polypropylene together.

People often ask me, “What is polypropylene?” To put it simply, it is a type of plastic that can be used in many, many ways. You can think of it as a very important kind of plastic. It is the second most popular plastic after polyethylene. Polypropylene, which is also called PP, is a thermoplastic polymer. The “thermo” part means you can heat it until it melts. Then, you can shape it again. It will not lose its useful features. This makes it very good for recycling.

The “polymer” part means it is made of long chains. These chains are made of a smaller part, or monomer, called propylene. This great material was first made in the 1950s. It soon became a top choice for a huge number of products. One of the first things you will see about polypropylene is that it is not heavy. In fact, it is one of the lightest plastics you can find.

But do not think that its low weight means it is weak. This plastic is strong, hard, and has good fatigue resistance. This means it can bend many times without breaking. Think about a plastic box with a lid that is connected by a thin piece of plastic. You can open and close that lid thousands of times. That is because of polypropylene’s special ability to resist getting tired and breaking. You can find polypropylene in two main forms. It can be a hard, solid plastic or it can be a soft fiber. As a solid plastic, it is used for car parts and tables and chairs. As a fiber, it is used for things like rope, carpets, and clothes. The reason it is so widely used is because of its special mix of features. It has great chemical resistance. This means it will not be damaged by many chemicals. It also has a high melting point. That is why we use it for food boxes that can go in the microwave.

So, how do we get this very useful plastic? The way we make polypropylene is very interesting. It all begins with a gas called propylene. This propylene monomer is the main building block. The process is called polymerization. That is just a long word for linking lots of tiny propylene parts together to make long chains. It is like making a long chain with paper clips. Each paper clip is a propylene monomer. The whole chain is the polypropylene polymer.

To make this happen, scientists use special things called catalysts. Catalysts are like helpers. They help the propylene monomers link up in the right way. The temperature and pressure are also controlled very carefully. This helps to create different kinds of polypropylene with different features. Based on how the propylene parts are lined up, the plastic can be very hard or more bendy.

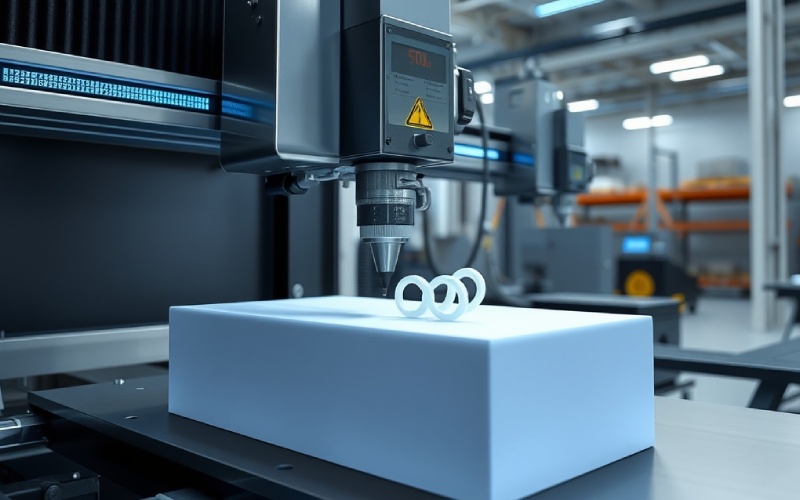

When the polymerization is done, the polypropylene looks like a powder or a resin. This polypropylene resin is then melted. It is pushed through a machine to make long strings. These strings are cooled down and cut into small pieces called pellets. These pellets are what factories use to make all the polypropylene things we use. They can melt the pellets and use a process like injection molding to give the polypropylene its final shape. This could be a car bumper or a cup for yogurt. Making polypropylene is a complex process. It gives us one of the most useful plastic materials that can be used for many things.

When I talk about polypropylene, I am not talking about just one thing. There are a few different types of polypropylene. Each one has its own special features. The main difference is in how the propylene parts are put together. Another difference is if other monomers are mixed in. The three main types are homopolymers, random copolymers, and block copolymers.

First, let’s look at polypropylene homopolymer. This is the most common kind of polypropylene. It is made using only propylene monomers. You can think of it as “pure” polypropylene. This type is very hard and strong. It is great for things that need to be strong but not heavy. You can find it in things like packaging, cloth, and pipes.

Next, there are polypropylene copolymers. These types are made by mixing propylene with another monomer, like ethylene. There are two kinds of copolymers. One is a random copolymer. Here, the ethylene parts are mixed in all over the polypropylene chain. This makes the plastic more bendy and clearer than a homopolymer. It is often used for things like food boxes.

The other type is a block copolymer. In this kind, there are big groups of ethylene monomers in the chain. This makes the material much tougher. It is very good at taking hits, even when it is cold. Because it is so strong, it is used for things that need to be very durable, like car bumpers.

Also, the way the polymer chain is built can be different. This is where we get names like isotactic polypropylene, syndiotactic polypropylene, and atactic polypropylene. Most of the polypropylene we use is isotactic. This means that all the side groups on the chain are on the same side. This neat structure makes the plastic strong and hard.

| Type of Polypropylene | Seperti Apa | Untuk Apa Ini Digunakan |

|---|---|---|

| Homopolimer | Hard, strong, can handle heat. | Packaging, cloth, pipes, electrical parts. |

| Random Copolymer | Bendy, clear, good at taking hits. | Food boxes, clear packaging, thin products. |

| Block Copolymer | Very tough, very strong against hits, even when it’s cold. | Car parts, bags, electrical parts. |

Now, let’s look at the physical properties of polypropylene that make it so useful. One of the easiest things to see about this polymer is its low density. This means it is very light for its size. In fact, PP is the lightest of all the common plastics. This means for the same amount of weight, you can make more parts with polypropylene than with other plastics. This low weight is a big plus for many things, especially for cars. Lighter cars use less gas.

Another key physical property is its melting point. Polypropylene has a high melting point when you compare it to other common plastics. The melting point of isotactic PP is about 171°C (340°F). Because it can handle a lot of heat, polypropylene is a great choice for things that need to be cleaned with heat. This includes medical tools and food boxes that you can put in the microwave. It will not change shape in the dishwasher.

Polypropylene is also a semi-crystalline material. This means that some parts of the polymer chains are very neat and organized. Other parts are more messy and jumbled. This mix of neat parts and jumbled parts gives polypropylene a good mix of being stiff and strong. It is strong enough to be used as an engineering plastic sometimes. But it is also bendy and has great fatigue resistance. This is why it is perfect for making “living hinges” on bottle caps. These are the thin parts that can bend again and again.

When we look at the chemical and physical properties of polypropylene, we see what makes this plastic last so long. One of its best features is its great chemical resistance. Polypropylene is strong against many kinds of chemicals. This includes many acids and other liquids. This means you can keep things like cleaning liquids in a PP container. You do not have to worry about the container breaking down. This good chemical resistance makes it a great choice for factories and labs.

Another important feature is that it doesn’t soak up water. Polypropylene stays dry, which makes it perfect for things that get wet. This is a big reason why it is used so much in packaging for food and drinks. It acts as a good wall against water, which helps keep food fresh. Its moisture barrier properties are a big plus in many packaging applications.

When it comes to electricity, polypropylene is very good at stopping it. It does not let electricity pass through it. So, it is often used for the plastic cases around electronics and for covering electrical wires. The electrical properties of PP make it a safe material for these jobs. Its thermal properties are also great. We already said its high melting point is a good thing. It also holds its shape better than some other plastics when the temperature changes. But, it can get weak and break in very cold weather, below 0°C.

When we talk about how strong a plastic is, we are talking about its mechanical properties. And polypropylene has some very excellent mechanical properties. PP is known for being a tough and bendy material. This is especially true when it is made as a copolymer with ethylene. Because it is so tough, it can sometimes be used as an engineering plastic instead of materials like ABS.

The stiffness of polypropylene is another important mechanical feature. This means it is a hard material that does not bend easily. That is why it is used for things like car dashboards and plastic chairs. The way the polymer chains are put together, which we call its mechanical and morphological properties, is very important for this. The neat structure of isotactic polypropylene makes it harder and stronger than the messy structure of atactic PP.

One of the best mechanical properties of polypropylene is its amazing fatigue resistance. This is the power of a material to be bent many times without breaking. This feature is so good in polypropylene that it is used to make “living hinges.” These are thin pieces of plastic that connect a lid to a box and can be bent millions of times. This makes PP a very strong material for a wide range of uses. We can also make polypropylene stronger by adding other things to it. For example, fibre reinforced polypropylene is made by adding glass fibers to the plastic. This makes the polypropylene even stronger and harder. It can then be used for jobs that need even more strength.

You will often hear polypropylene called a “commodity plastic.” What does this mean? A commodity plastic is a type of plastic that is made in very large amounts. It is also sold at a low cost. Polypropylene is the second most common commodity plastic in the world. The first is polyethylene. Its low cost is a big reason why so many people use it. Companies can make a lot of things with polypropylene without spending too much money.

But it is not just the low cost that makes polypropylene a top commodity plastic. It is also because it gives you a lot of good features for that low price. As we have talked about, PP has a great mix of properties. It is not heavy, it is strong, it has good chemical resistance, and a high melting point. Because it can do so many things, it can be used in a huge number of different products. It is used for packaging, automotive parts, and cloth. Not many other materials can do so much for such a low price.

How easy it is to make things with polypropylene also makes it popular. Polypropylene can be processed without a lot of trouble. It can be shaped using methods like injection molding. This makes it easy for companies to turn the raw polypropylene pellets into things they can sell. The fact that it can also be recycled makes it even better. This mix of low price, great features, and easy manufacturing makes polypropylene one of the most important and widely used plastics in the world.

Until now, we have mostly talked about polypropylene as a hard plastic. But it can also be used as a fiber. Polypropylene fiber, or pp fiber, is a man-made fiber. It is made by melting polypropylene resin and pushing it through very small holes. This makes long, thin threads. These fibers have some great features that make them useful in many different products.

One of the best things about polypropylene fiber is that it is very light and does not soak up water. This makes it great for sports clothes and outdoor items. It helps to pull sweat away from your skin. You will also find it in carpets because it is very strong and does not get stained easily. Because it is so tough and does not rot, polypropylene fiber is also used to make ropes and fishing nets. It is also used in special fabrics for building roads and gardens.

A very interesting use of polypropylene fiber is in concrete. Yes, that is right. Small pieces of polypropylene fiber are sometimes mixed with concrete. This makes the concrete stronger and helps stop it from cracking. This polypropylene fiber reinforced concrete is stronger and can take more pressure than normal concrete. From clothes to building materials, the special features of pp fiber make it a very useful material.

The automotive world uses a lot of polypropylene. If you look at a car made today, you will see polypropylene in many places, both inside and outside. One of the main reasons it is so popular for cars is because it is not heavy. By using light plastics like PP instead of heavy metal, car makers can build cars that use less gas.

On the outside of a car, polypropylene is often used for bumpers and other body parts. PP is a great choice for these parts because it has excellent impact resistance. This means it can take a hit without breaking and can go back to its old shape. It is also strong against bad weather and chemicals.

Inside the car, you will find even more polypropylene. It is used for dashboards and door panels. Its stiffness and good mechanical properties make it a strong material for these parts. You will also find polypropylene fiber in the car’s carpets. Under the hood, types of polypropylene that can handle heat are used for things like battery boxes. The mix of low cost, low weight, and great features makes polypropylene a very important material for making cars today.

Packaging is another area where polypropylene is very useful. It is especially useful when it is made into polypropylene film, or pp film. This is a thin, bendy sheet of plastic. It is used to wrap and keep many kinds of products safe. One of the great things about pp film is that it can be made very clear. This makes the products inside look better to people who want to buy them.

There are a few kinds of polypropylene film. A common type is Cast Polypropylene (CPP). It is known for being very clear and smooth. But the most common type is biaxially oriented polypropylene, or BOPP. This bopp film is made by stretching the plastic sheet in two directions. This stretching makes the film much stronger and harder. BOPP film is a great wall against water. This helps keep foods like chips and candy fresh.

The high melting point of polypropylene is also a big plus for packaging material. It means that pp film can be used for packaging that gets hot, like for items that need to be cleaned with heat. Polypropylene film can also be used in many ways. You can print on it, and you can add other layers to it to make it better at blocking gases like oxygen. Because it has a low cost, is strong, and can be used in many ways, polypropylene film is a top choice for a huge number of packaging applications.