Biarkan Istar membantu Anda memulai proyek Anda dengan pengalaman dan pengetahuan kami!

Unggah file desain dan persyaratan produksi Anda dan kami akan menghubungi Anda dalam waktu 30 menit!

Polish is not just for making things look nice. A good polish can decide if a project is a success or a failure. Polishing is not just about making something shiny. It is a very important step. It makes a part work better, helps it last longer, and helps it stand up to weather.

In this guide, I am going to show you everything I know about polishing. We will talk about what it is and why it is so important. We will also look at the different ways you can do it. I will give you my best tips for getting the best possible polishing finish. If you want to make your metal parts look great and work even better, then this guide is for you.

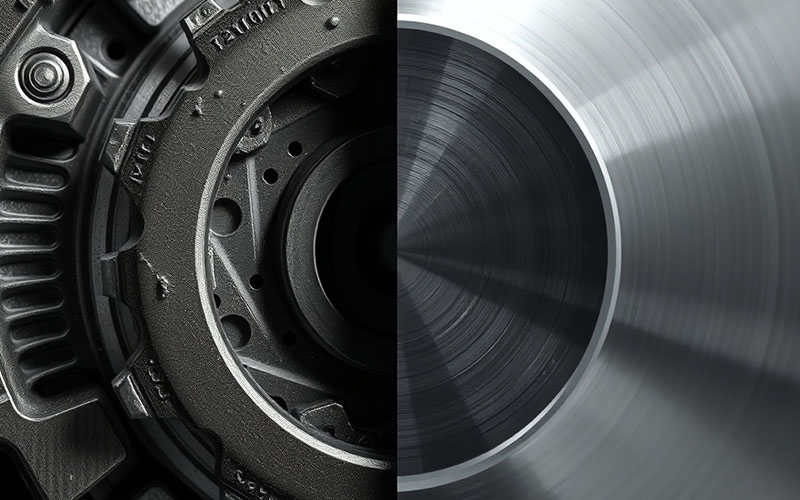

So, what are we really doing when we polish something? Basically, the polishing process is all about making a surface smooth. Imagine a piece of metal after it has been cut or shaped. It might look smooth when you look at it from far away. But if you look at it with a microscope, its surface has many tiny high spots and low spots. We call this a rough surface. The main purpose of polishing is to remove these tiny flaws.

Polishing involves using an abrasive material. You use it to carefully rub away the high spots on the surface of a workpiece. This action makes the surface much smoother and more even. You can use this process to remove imperfections. Some examples are a scratch, a nick, or a burr. You usually use a few different abrasives. You start with a rough one and then move to progressively finer ones. Each step makes the surface finish better until it looks and feels the way you want.

The final result is a very smooth surface. This surface is often shiny and reflects light. Polishing is used to create a shiny surface. This surface not only looks good, but it also has other good qualities. For instance, a smooth metal surface slides more easily and is simpler to clean. The final finish can be anything from a dull look to a very bright, mirror-bright finish. It all depends on the tools and compound that you use.

I have seen people not do a good polish because they want to save time. But this almost always causes more problems for them later on. A very good surface finish is more than just a nice shine. For any metal part, the quality of its surface has a big effect on its quality and performance. A rough surface can wear out more quickly. It can also trap dirt. And it might break when you put pressure on it.

A smooth, polished surface has many useful advantages. One of the most important advantages is that it helps stop corrosion. When a metal surface is rough, more of its area is touching the air and water. This can cause oxidation and rust. Polishing helps to make a smooth shield that is harder for corrosion to start on. This is why polishing stainless steel is very important for tools used in hospitals and for making food. It helps to prevent contamination.

Also, the surface texture changes how parts work with each other. In machines, a smoother surface finish on parts that move means they slide more easily. They do not get as hot, and they work better. Polishing may also be a very important step to get a metal ready for other finishing processes, like painting. A good finish makes sure that these coatings stick well and last for a longer time. In some jobs, like metallography, you need a perfect surface finish to study the inside of a metal.

When people talk about polishing, they are often thinking about only one way to do it. But there are a few different types of polishing. The best one to use changes based on the metal, the part’s shape, and the desired finish. I put them into three main groups. These groups are mechanical polishing, chemical polishing, and electropolishing.

Most people know about mechanical polishing. It means you physically rub a workpiece with an abrasive to get a smooth finish. You do it with your hands or with tools, so you can control it very well. It is one of the most common finishing processes.

Chemical polishing is a method that is not used as often. It uses chemical solutions to make a metal surface smooth. The workpiece is put into a special liquid. This liquid has a chemical reaction with the metal. This reaction removes the high spots. This leaves behind a smoother surface finish. This way is great for small parts or parts with tricky shapes that are hard to polish by hand. Electropolishing is a kind of chemical polishing that uses electricity to make it work faster. We will talk more about that next.

I have spent a very long time doing mechanical polishing. You have to practice to get good at it. The main idea is easy. You use rubbing and an abrasive to wear down the surface of a metal workpiece. You can do this by hand. You can also use tools like polishing machines or electric drills. The process usually begins after the main cutting or shaping work is finished. If the surface is very rough, you might begin with a sandpaper that is around 80 grit.

The main tools you use are polishing wheels and a buffing wheel. These are made from things like cloth or felt. You put a polishing compound on the wheel. This compound has an abrasive material mixed into a base, which is often a greasy material like wax. When the wheel spins, the tiny abrasive bits rub against the metal. This removes a very thin layer of the material. The important thing is to begin with a rough abrasive to remove the bigger flaws. Then you move to finer abrasives to make the finish better.

The polishing and buffing process has two main parts. The first part uses a harder wheel and a stronger abrasive compound to make the surface level. The second part uses a softer wheel and finer abrasives. These are called buffing compounds. They bring out the shine and create a reflective surface. A good finish requires you to work carefully, but the results you get from mechanical polishing can be wonderful.

Sometimes, mechanical polishing is not the best way to do it. If you have a workpiece with a very tricky shape, it can be very hard to get an even surface finish with a wheel. This is when electropolishing is very helpful. I have found it to be a great answer for certain kinds of polished parts.

Electropolishing is also called electrolytic polishing. It is a process that uses chemicals and electricity. The metal part is put into a special liquid and hooked up to a power source. It becomes the positive end. Another piece of metal becomes the negative end. When you turn on the power, it makes the surface of the workpiece dissolve. The amazing part is that the high spots on the metal surface dissolve more quickly than the low spots. This makes the surface smooth on a microscopic level. It creates a very clean and defect-free finish.

One of the great things about electropolishing is that it creates a surface finish that is very good at resisting corrosion. It reduces surface roughness but does not add stress like mechanical polishing can. It is great for medical parts and parts for the food industry. This is because the very smooth surface is easy to make sterile and prevents the buildup of germs. But, it does need specialized equipment. You also have to be careful with the chemicals that are used in electropolishing.

Like any other process, polishing has good sides and bad sides. It is good to understand them before you decide to use it for your project. I have made a simple table to show the pros and cons of polishing.

| Pros of Polishing | Cons of Polishing |

|---|---|

| Makes It Look Better: Creates a nice, shiny finish. | Takes a Lot of Time: It can take a while to get the perfect finish. |

| Helps It Last Longer: A smooth surface finish helps stop corrosion and tarnish. | Removes Material: Polishing may take off a little bit of metal, which could be a problem for exact parts. |

| Works Better: Reduces surface roughness and makes moving parts slide easily. | You Need to Be Skilled: To get a great polished finish, you need practice and knowledge. |

| Easier to Clean: A smooth surface is easy to clean and helps stop contamination. | Can Hide Problems: A very shiny surface can sometimes cover up problems deep in the metal. |

| Better for Coatings: It makes a great surface for paint or other coatings to stick to. | Can Be Expensive: Professional polishing services or buying specialized equipment can cost a lot of money. |

I think the good things are usually more important than the bad things. This is especially true for parts where the surface quality is very important. A good finish is a good investment in the part’s future. The process of polishing is often used for things where both looks and how it works are important.

Getting a great finish is all about using the right method. You can have the best tools. But if you do not use them the right way, you will get a bad result. Here are a few polishing techniques I have learned. They will help you achieve the desired surface.

First, think about how you move. There are two main ways to move: the cut motion and the color motion. The cut motion is stronger. You use it with a rougher abrasive compound to remove material and make the surface level. You will use medium to hard pressure. You will also move the workpiece in the opposite direction that the wheel is spinning. For the color motion, you use much less pressure. You use this for the final finish. You move in the same direction as the wheel’s spin. This makes the final shine appear without taking off much metal.

The direction that you move is also very important. When moving the workpiece, you should always change your direction between the different steps. If you only polish in one direction, you will make tiny lines in the finish. By changing your direction each time you use a new, finer abrasive, you make a criss-cross pattern. This makes sure that the scratches from the last step are all gone. This is a very important part of achieving an optimal polishing finish.

Choosing the right abrasive compound is maybe the biggest choice you will make in the whole polishing process. The compound you choose will decide how fast you can remove a scratch. It will also decide what kind of final surface finish you will get. The choice changes based on the kind of metal you are working on. It also changes based on how rough the surface is when you start.

A polishing compound has two main parts. It has the abrasive material and the base that holds it. The common materials used for abrasives are things like aluminum oxide and silicon carbide. The base is often made of greasy things like wax and kerosene. The color of the compound can often tell you how rough it is. For example, a black or brown compound is usually very rough and is used for cutting. A white or red compound is very fine and is used for the final mirror-bright finish.

When I begin a project, I check the metal surface. If there is a deep scratch, I will start with a very strong abrasive compound. After that, I will clean the workpiece and change to a medium compound. Last, I will use a fine compound to make it shine. It is a process that you do step by step. If you skip a step to go faster, you will only make the job more difficult. You will also end up with a bad finish. The polishing uses a certain compound for a certain job on a certain metal.

After all my years of doing this work, I have a few simple rules I use every time. These are my top tips for achieving the best surface finish you can get. If you remember these things, you will be on your way to getting a finish that looks like a pro did it.

I have made almost every mistake that you can make. So let me help you not make them. Many finishing processes seem easy, but little mistakes can mess up all your hard work. The most common mistake I see is people not being patient. People try to do the job too fast. They end up with a poor final finish.

Another very big mistake is using the wrong abrasive material for the metal. For example, some abrasives are great for steel. But they are too hard for a softer metal like aluminum. They will just make a new, deep scratch. Always make sure your compound is the right one for the metal you are polishing. Making it ideal means you need to match your tools to the job.

Finally, not being clean is something that ruins a project. If you do not clean the workpiece the right way between steps, you will pull rough abrasive bits into your finer polishing steps. This will give you a cloudy finish that has tiny scratches you cannot get out. The desired finish is achieved only when you are careful with every part of the polishing process. Taking your time and being clean will save you from getting very upset. These careful steps will give you the best polished metal surfaces.

Here are the most important things to learn from my guide to polishing: