Lasciate che Istar vi aiuti a iniziare il vostro progetto con la nostra esperienza e il nostro know-how!

Caricate i file del vostro progetto e i requisiti di produzione e vi risponderemo entro 30 minuti!

Lavorazione meccanica is a simple idea. It’s the process of taking a piece of material, like a block of metal or plastic, and cutting away parts of it to create a desired shape. Think of a sculptor with a block of marble. The sculptor chips away everything that doesn’t look like a statue. Machining is a lot like that, but with more power and incredible precision. This guide is for anyone who’s ever wondered how things are made. We will explore the various types of machining, from traditional methods to high-tech processes.

At its core, machining is a manufacturing process that shapes parts by taglio. To be more specific, machining is a subtractive manufacturing process. This means we start with more material than we need and subtract, or remove, the excess. The machining process removes material from a workpiece to achieve a final shape, size, and finish. This process where material is cut away is the opposite of additive manufacturing, like 3D printing, where material is added layer by layer.

This fundamental material removal process is behind so many things we use every day. From the engine block in your car to the tiny screws in your smartphone, a machining process was likely involved. The goal is always to create a part with a specific geometry and a high degree of accuracy. The need for precision is why this machining process is so critical in modern manufacturing industries. The entire machining process is about control and accuracy.

When most people think of machining, they are usually picturing a conventional machining process. The concept is simple: a sharp cutting tool makes physical contact with the workpiece to shear away material. This method of traditional machining relies on a strong, hard cutting tool that can cut a softer workpiece. The machine tool itself is the larger piece of equipment that holds the workpiece and moves the cutting tool.

This type of machining operation can be done by hand, but it is most often done by powerful machines. A conventional machining operation generates a lot of heat and creates chips, which are the small pieces of material that have been cut away. The beauty of this machining process is its directness. You can see the cutting tool doing its work, carving out the part right before your eyes. This is a very common machining process for a reason; it’s effective and well-understood.

One of the most common machines you’ll see is the mill. A mill is a true workhorse. A milling machine uses a rotating cutting tool to remove material from a workpiece. The mill is incredibly versatile. A modern mill is often a CNC machine. Fresatura CNC uses a computer to control the movement of the mill and the workpiece, allowing for amazing precision. This computer-controlled process produces parts with identical shapes over and over. A good mill operator knows just how to set up the job.

There are many types of milling operations. We can talk about the two main types of milling: face milling and peripheral milling. Face milling uses the face of the cutting tool to create flat surfaces. Peripheral milling uses the side of the cutting tool, like an end mill, to cut slots and contours. An end mill looks a bit like a drill bit but is designed to cut sideways. The mill can be a simple manual machine or a complex, multi-axis CNC machine. Because it can do so much, the mill is a versatile machining process. Every shop has a mill; it’s that important. The mill is a core part of any machining process. The various milling operations show how adaptable a mill can be.

Another fundamental machining operation is turning. If a mill has a spinning tool and a (mostly) fixed part, turning is the opposite. In the turning process, the workpiece spins at a high speed while a stationary cutting tool is moved along its side. Imagine putting a block of wood on a potter’s wheel and holding a chisel against it as it spins. That’s the basic idea. This machining process is done on a machine called a lathe.

Turning is used to create round or cylindrical parts. Think of things like shafts, pins, and baseball bats. This is a very efficient machining process for making these kinds of shapes with great precision. Skilled machinists perform operations like cutting threads for a screw or creating a smooth, tapered shape on a lathe. It’s a classic type of machining operation that is still essential today, both on manual lathes and on a CNC machine.

Beyond milling and turning, there are other very common processes. Drilling uses a spinning drill bit to create a round hole in a workpiece. But in the world of precision machining, we often need more than just a simple hole. That’s where other operations like boring and reaming come in. Boring makes an existing hole larger with more accuracy. Reaming is a precision machining process used to slightly enlarge a hole to a very exact size and give it a smooth finish. This is considered a finishing operation.

Another interesting machining process is knurling. Knurling is a machining process that creates a patterned texture on a surface, usually for grip. Think of the handle of a metal tool or a control knob. That crisscross pattern is often made through knurling. These different machining operations are often used together. A part might be milled to shape, then drilled, then reamed to achieve high precision. Sometimes a secondary finishing process is needed to get the part just right. This precision machining process is key for parts that need to fit together perfectly.

Now, let’s step into the high-tech side of the shop. So far, we’ve talked about the conventional machining process, where a physical cutting tool shears away material. But what if the material is too hard to cut? Or what if the shape is too delicate or complex? That’s where a non-conventional machining process comes in. These modern methods don’t use a sharp cutting tool in the traditional sense. Instead, machining uses various forms of energy to remove material.

The world of conventional and non-conventional machining is fascinating. The biggest difference is the lack of direct contact. A non-traditional machining process can use electricity, light, sound, or even chemicals to shape a part. The process used depends entirely on the job. This type of machining opens up possibilities that are impossible with a standard mill or lathe. This machining process that utilizes energy is perfect for exotic materials and complex shapes requiring high precision.

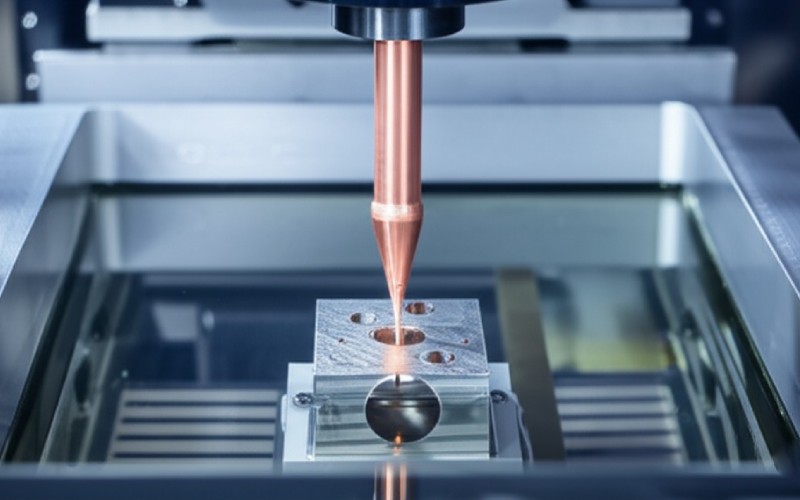

One of my favorite types of non-conventional machining is discharge machining. It’s also known as electric discharge machining or spark machining. The full name is electrical discharge machining (EDM). This process involves using a controlled electrical spark to erode, or melt away, material. Imagine two wires, one being the tool (called an electrode) and the other being the workpiece. When you bring them very close without touching, a spark can jump between them. EDM uses thousands of these tiny sparks per second to slowly and precisely vaporize the material.

The entire process is often used in a special oil that helps flush away the tiny bits of removed material. There is no physical contact, which means no cutting forces. This makes discharge machining ideal for machining very hard metals like titanium or creating very delicate, thin-walled shapes that would break under a normal cutting tool. This machining operation is a game-changer for tool and die making. Discharge machining is a remarkable machining process.

Besides EDM, there are many other amazing non-traditional methods. We can group them into a few categories. One is beam machining. This includes laser beam machining, which uses a powerful, focused beam of light to melt or vaporize material. Electron beam machining uses a high-speed stream of electrons in a vacuum, and ion beam machining uses charged atoms for super-fine work.

Another group is jet machining. Water jet machining uses a very high-pressure stream of water to cut. It’s a cold machining process, so it’s great for machining softer materials like plastic or wood without heat damage. For harder materials, we can use abrasive jet machining. Abrasive jet machining uses a jet of gas mixed with tiny abrasive particles to blast away material. Then there is plasma arc machining, which uses a jet of superheated, ionized gas. Plasma arc machining uses a high-velocity stream of plasma to cut through thick metals quickly.

Finally, we have processes that use sound or chemicals. Ultrasonic machining uses high-frequency vibrations to chip away at hard, brittle materials like glass or ceramics. Chemical machining uses strong chemicals to etch away material. This chemical machining process is great for removing small amounts of material over a large area. A related method is electrochemical machining, which is like running a plating process in reverse to dissolve material. There are even more specialized methods, like magnetic field assisted machining. Each type of machining operation has its own special use.

With so many options, how do you choose the right type of machining? It comes down to a few key questions. First, what is the material? The types of materials you are working with will rule out some methods and favor others. Second, what is the final shape? Simple shapes might be fine for a conventional machining operation, but complex curves may need a 5-axis CNC machine or a non-conventional machining process.

Third, what level of precision is needed? For general parts, a standard mill is fine. For parts that need to fit perfectly, you might need a precision machining method like EDM or a special finishing process. Finally, you have to think about cost and speed. The efficiency of the machining process is always a factor. Some processes are very fast but less precise, while others are slow but incredibly accurate. Choosing the right machining process used is a balancing act between the part’s requirements and the budget.

In any conventional machining operation, the cutting tool is everything. You can have the best, most expensive CNC machine in the world, but with a dull or incorrect cutting tool, you will make bad parts. The material, coating, geometry, and sharpness of the cutting tool directly affect the quality of the finish, the precision of the part, and the overall speed of the machining process.

Even in non-conventional methods, the “tool” is just as important. In EDM, the electrode is the tool. In laser cutting, the focused beam of light is the tool. The tool used in any machining process is the key element that interacts with the workpiece. Paying attention to the cutting tool is one of the most important lessons I’ve learned. It’s the part of the machining operation that does the actual work, and it deserves all the credit. A good machining process always starts with a good cutting tool.