Lasciate che Istar vi aiuti a iniziare il vostro progetto con la nostra esperienza e il nostro know-how!

Caricate i file del vostro progetto e i requisiti di produzione e vi risponderemo entro 30 minuti!

Delrin is a special kind of plastic. But it is so strong and stiff that you can count on it. It often works even better than metal. It is a material that does a lot of hard work in making things.

Maybe you are an engineer, a designer, or just someone who likes to build things. If you are looking for the best material, you should learn about Delrin. This article will be your simple explanation. I am going to show you everything you need to know. We will talk about what Delrin is and how you can use it. We will look at its great material properties. After you read this, you will understand why this plastic, which can be used in many ways, is a material that changes everything. You will also see why it is a great replacement for metal.

Let’s begin with the simple facts. Delrin is a brand name, like how people say Kleenex when they mean tissues. The real name for this material is Polyoxymethylene. That name is very long and hard to say! This is why most people who work with it just use its short name, POM. You may also hear it called acetal. Delrin is a special kind of acetal. It is called an acetal homopolymer. This just means that the way it’s built inside is very clean and very strong.

You can think of Delrin as a plastic that works really, really well. It is not like the weak plastic you find in food wrappers. Delrin is an engineering thermoplastic. This means it is an engineering-grade material made for tough jobs. Because it is a thermoplastic, you can heat it until it melts, shape it, and then let it cool. You can do this again and again. This makes it a great material for making things with processes like injection molding. The special way it’s built makes it a semi-crystalline polymer. This is what gives it its wonderful strength and stiffness.

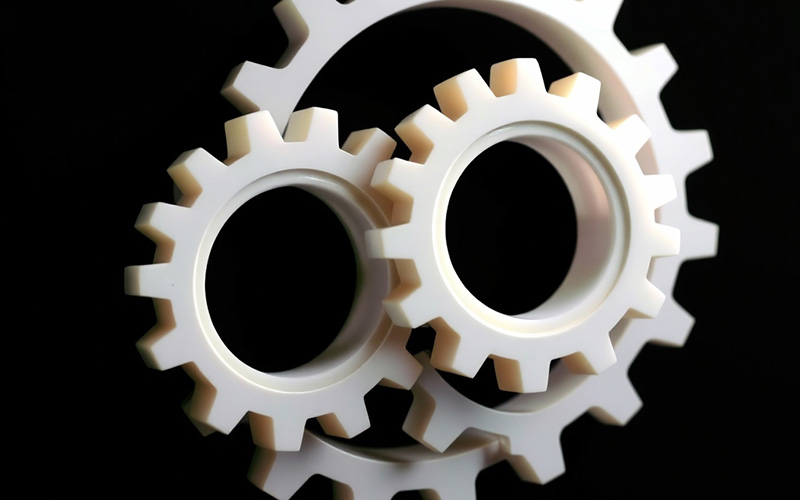

The first time I used Delrin was for a project that needed a small, strong gear. The metal gear we tried at first was too heavy. It also needed oil to work smoothly. The Delrin gear was light and quiet. It was so slippery that it did not need any oil. That was the moment I knew this plastic material was very special.

The story of this wonderful plastic starts way back in the 1920s. A very smart German chemist named Hermann Staudinger was learning about very big molecules. He found out how to link them together in long chains. He called these chains polymers. This was the start of the plastic business we know today. He later won a very important award for his work.

But the first version of this polymer was not very strong or lasting. It would fall apart too easily. Later, in the 1950s, smart people at the DuPont company figured out how to make it strong and stable. The material was commercially synthesized when they found a way to put a “cap” on the ends of the polymer chains. It was created by distilling a chemical called formaldehyde. This was then combined with other catalysts via a process called polymerization.

This big, new discovery led to the strong material you can count on. We call it Delrin today. It quickly became one of the most important manufacturing materials anywhere. It proved to everyone that a plastic could be strong enough for serious machine parts.

What is it that makes Delrin so great? The answer is in its amazing physical properties. When I pick a material for a job, I always look at the facts. The properties of Delrin are very clear. This plastic offers a mix of good points that are hard to find in other materials.

Here are some of the main plastic properties of Delrin:

| Proprietà | Cosa significa | Why It Is Important |

|---|---|---|

| High Strength & Stiffness | Delrin is very stiff and strong. It fights against bending. It also does not break easily when a lot of weight is on it. | It’s great for parts that have to carry weight and must not bend, like gears or parts that hold things up. |

| Low Friction | It has a very low coefficient of friction. It is naturally slippery when it rubs against metal and other types of plastic. | Parts can slide easily and do not need oil. This is perfect for bearings and other parts that move. |

| Great Wear Resistance | Delrin lasts a long time when things rub against it. This rubbing is called abrasion. It does not wear out quickly. | It makes parts that last a long time, so you do not have to change them often. |

| Great Dimensional Stability | It keeps its shape really well. This is true even if it gets hotter or colder, or if the air gets wet. It also resists creep. | This means you can make parts that are the perfect size and shape, and they will stay that way. |

| Good Chemical Resistance | Delrin is not harmed by many common chemicals, like fuels and solvents. | It can be used in automotive parts or in factories where it might touch different liquids. |

These excellent mechanical properties are what make Delrin ideal for so many different jobs. Its high stiffness and strength help it bridge the gap between metals and regular plastics.

People ask me this question all the time. For a very long time, metal was the only thing you could use for strong parts. But materials like Delrin have changed things. There are many good reasons why you might pick this strong plastic instead of a metal like aluminum or steel.

First, Delrin is much lighter than metal. This is a big plus in businesses like making planes and cars. In those areas, even a little bit of weight makes a big difference. Using Delrin lets you make thinner and lighter parts but keep them strong. I once worked on a project where we changed parts from steel to Delrin plastic components. This change lowered the final product’s weight by 60%.

Second, Delrin does not rust. Metal parts often need special paint or coatings to keep them safe from water and other things. Delrin has a natural corrosion resistance. You can place it in a wet area, and it will be completely fine. This saves you money and helps parts last longer. The excellent resistance to many chemicals makes it a better pick than most plastics and metals.

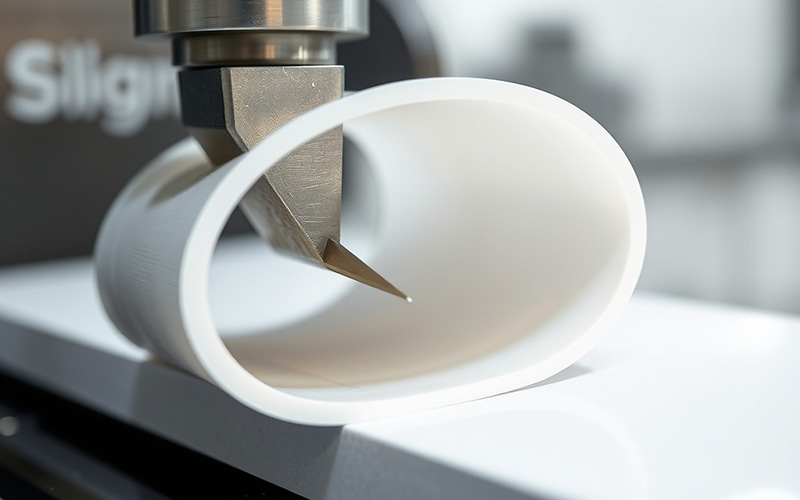

One of the things I like most about Delrin is how easy it is to cut and shape. This is called machinability. Have you ever tried to machine a soft, sticky plastic? If you have, you know it can make you feel very upset. The plastic can melt, your tools can get sticky, and the cut will not be clean. Delrin is the complete other way. To machine it feels like cutting a firm block of butter.

It is one of the easiest types of plastic to machine. You can use the same tools that you would use to cut metal. When you machine Delrin, you get clean, sharp cuts and a smooth feel. When you cut it, it makes small chips that break off and fall away. They don’t melt and stick to your cutting tool. This is a big reason why Delrin is used in Lavorazione CNC. With CNC machining, you can create highly precise parts that are the exact size you need.

The material’s stiffness is also a big help. It does not shake or bend while being cut. This helps you get a very nice surface finish as soon as the machine is done. For any project where I need to build a prototype or a few special parts, I often choose Delrin and CNC machining. Companies that do digital manufacturing, like Protolabs, are very good at this. They can make high-precision parts with Delrin in a very short time.

Yes, it is a great pick! Delrin is wonderful to machine. It is also one of the best materials for injection molding. This is the way you can make thousands or millions of plastic parts that are all exactly the same. The cost for each part is very low. The process works by melting little plastic balls and pushing the hot, liquid plastic into a metal mold.

Delrin is great for injection molding. This is because when Delrin gets hot, it turns into a liquid that flows very easily, almost like water. This is perfect for getting into all the little spaces in a mold. It works well for molds with tiny details or very thin walls. You can create shapes with lots of details that would be hard to make with a machine. The excellent dimensional stability of Delrin also means the parts keep their shape as they cool. They do not get smaller or twist out of shape.

This ability to resist creep is also very important for injection molding projects. If a Delrin part has weight on it all the time, like a spring or a clip, it will keep its shape for a long, long time. It will not slowly change its shape. Because you can trust it to work, you see many parts made by injection molding from Delrin. They are in everything from cars to things we use every day. It is a great way to produce a finished plastic part in large numbers.

Not all Delrin is the same. Just like there are special mixes of metal, there are different types, or grades, of Delrin. They are made for certain tasks. Knowing about the different kinds can help you with your material selection. There are many special types, but you will most often see two common ones.

The first one is called Delrin 150. This is the normal, do-everything type. It has the best mix of mechanical properties. It has very good strength, stiffness, and it is hard to break. It is also one of the best kinds for machining. When a person just says “Delrin,” they are probably talking about this type. It is the number one pick for most common uses.

The second common type is Delrin 570. This kind has tiny glass pieces mixed into the plastic. These glass pieces make the material much stiffer and stronger than the normal kind. It is also better at fighting creep. You would pick Delrin 570 for parts that need to be as stiff as possible. It is also good for parts that will have a lot of weight on them all the time. The glass can make it a little harder to machine, but its high stiffness is worth it for the right job.

You can use Delrin to make so many things you can’t count them all. Because it has so many good points, you can find it in all kinds of businesses. Its variety of applications shows just how helpful this engineering plastic really is. Once you know what it looks like, you will start to see it in many places.

In the automotive world, Delrin is used for fuel system components. This is because gas does not harm it. You will also find it in parts for seatbelts, parts that help windows slide, and in door locks. In electronics, its strength is very useful. It also doesn’t let electricity pass through it. This makes it a good pick for switches, connectors, and cases for automotive and consumer electronics.

I have used Delrin myself to make a gear that works really well for a robot. I also made special clips for a factory machine and rollers for a moving belt. It is also a very popular material for parts in a pump and valve, bearings, and other smooth parts. Any time you need a part that is strong, slippery, and keeps its shape, Delrin is a good choice. This versatile plastic is perfect for making parts exposed to a lot of pushing and pulling.

No material is perfect for every job. Delrin has a few downsides or bad points that you should know about. When you know about them, you can make a better choice for your end-use project. It is always better to know what a material can’t do before you begin.

The biggest bad point of Delrin is that it is not good with strong acids and other strong chemicals. Things like battery acid can eat away at and ruin the plastic. But it does just fine with neutral chemicals and many kinds of solvent. You also need to be careful with sunlight. If a Delrin part is left in the bright sun for a long time, it can get weak and change its color. For things used outside, you would need a special UV-stabilized type.

Another thing to think about is that it can be hard to glue. Delrin has a slippery, low-friction surface. Because of this, most normal glues will not stick to it very well. You need to prepare the surface in a special way and use very strong glues to make it stick. Because of this, parts are often made to snap together or be held together with screws.

We have talked about a lot of things. You now know that Delrin, or POM, is a strong acetal homopolymer. It is strong, stiff, and has low friction. It is easy to machine and is great for injection molding. So, how do you know if it is the right material for you?

Your choice will always be about what your project needs. The material selection step is very important. You should ask yourself these questions:

If your answer was “yes” to most of these questions, then Delrin is probably a very good choice for you. The special properties make this plastic a great problem-solver. It does not matter if you are making a prototype with CNC machining and injection molding or making thousands of final parts. Delrin is a material that will do a great job for you. It is truly one of the very best materials in the world of plastic.