Lasciate che Istar vi aiuti a iniziare il vostro progetto con la nostra esperienza e il nostro know-how!

Caricate i file del vostro progetto e i requisiti di produzione e vi risponderemo entro 30 minuti!

I’ve been in the manufacturing world for a long time. I’ve seen technologies come and go. But one process that has only gotten better and more important is automotive injection molding. It’s the secret behind so many parts of the car you drive every day. This guide is for you if you’ve ever wondered how those plastic parts are made. It’s for you if you’re thinking about a project and need to know about automotive manufacturing. I will walk you through everything you need to know about this amazing technology. We will cover what it is, why the mold is so key, and how to choose the right company for your needs.

Let me break it down for you. Automotive injection molding is a manufacturing process. It is used to produce huge numbers of identical plastic parts for a vehicle. Think about your car’s dashboard, the door handles, the bumpers, and even the small clips you can’t see. Many of them are made using this exact technique. The process involves melting small plastic pellets and using high pressure to inject the molten plastic into a special tool called a mold.

The reason this process is so popular in the automotive industry is simple. It’s fast, it’s precise, and it’s a very cost-effective way to make a lot of parts. Once you have the mold made, you can create thousands, or even millions, of the same part with very high quality. This is key for any automotive oem or aftermarket parts manufacturer. The demand for high-quality, durable parts is huge, and automotive injection molding is the best way to meet it. The technology allows for complex shapes that would be hard or expensive to make any other way.

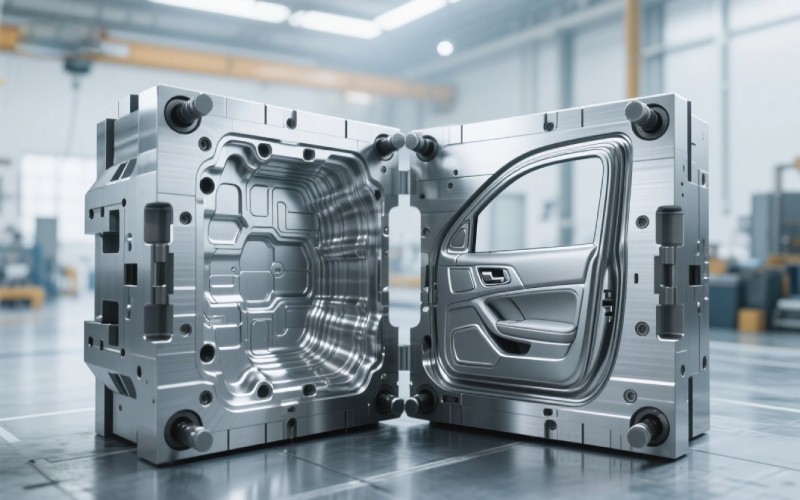

The mold is the heart and soul of automotive injection molding. You can have the best machine and the best plastic material, but without a good mold, you will get bad parts. A mold is usually made from steel or aluminum. It is a hollow block that has been carefully shaped on the inside to be the exact reverse of the part you want to make. When the hot plastic fills the mold, it takes on this shape. The quality of your final product depends completely on the quality of your mold.

Think of the mold as a very detailed jelly mold. If the jelly mold has scratches or flaws, your jelly will have them too. It’s the same with plastic injection. A well-made mold will have a smooth surface, precise dimensions, and a cooling system that helps the plastic set correctly. The design of the mold is critical. A good mold design ensures that the plastic flows evenly and fills every corner without creating weak spots. A bad mold can cause all sorts of problems, from parts that don’t fit to parts that break easily.

I’ve seen companies try to save money by getting a cheap mold. It almost always ends up costing them more in the long run. A poorly made mold wears out faster, needs more repairs, and produces lower quality parts. Investing in a high-quality mold from a good manufacturer is the most important step in the entire automotive injection molding process. This single tool, the mold, determines the success of your entire production run. A great mold is the key to making great car parts.

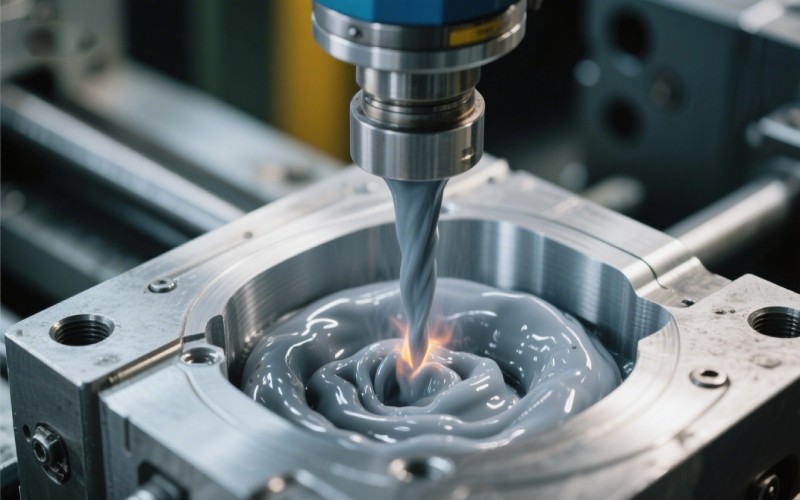

The molding process itself is like a well-practiced dance with a few key steps. First, small plastic pellets are fed into a big barrel. Inside the barrel, a large screw turns, pushing the pellets forward. As they move, heaters around the barrel melt the plastic into a hot liquid. This is the molten plastic we need for the process.

Next, the two halves of the steel mold are clamped together with great force. This is important to keep the mold shut when the plastic is pushed in. Then, the screw pushes forward like a plunger. It forces, or injects, the hot plastic out of the barrel and into the empty mold. The plastic fills the entire cavity of the mold. The mold is kept cool, so the plastic begins to harden almost immediately.

After a short cooling period, the mold opens up. Ejector pins inside the mold push the now-solid plastic part out. The part drops into a bin, and the mold closes again, ready for the next cycle. This whole process can take just a few seconds. This is why automotive injection molding is so faster than other methods. It’s a continuous cycle that can run 24 hours a day to produce a huge number of injection molded parts.

Choosing the right material is just as important as having a good mold. The type of plastic you use will decide how strong, flexible, or heat-resistant your part is. For a vehicle, you need parts that are durable and can last for years. There are thousands of different types of plastic, but a few are very common in the automotive injection molding world.

One of the most used is polypropylene. It’s a great all-around material. It’s used for things like bumpers, dashboards, and even the container for your car battery. It’s tough and has good chemical resistance. Another popular material is nylon. Nylon is very strong and is often used for gears, bearings, and other parts that need to handle stress. For parts that need to look good, like grilles or trim, manufacturers might use a material called ABS. It has a nice, glossy finish and is also very strong.

When I work with a client, the first thing we discuss is the part’s job. What does it need to do? Does it need to be a structural part? Does it need to handle high temperature? The answers help us pick the perfect plastic material. The choice of material affects the cost, the weight, and the performance of the part. A good automotive injection molding company will have experts who can help you choose the right material for your specific vehicle part. This is a key part of the design and manufacturing process.

Absolutely! This is one of the biggest strengths of automotive injection molding. The technique is so flexible that it can be used to make parts for both the inside and the outside of a car. The key is choosing the right plastic material and creating the right mold design for the job.

For interior components, you need parts that feel good to the touch and look great. Think about the dashboard, door panels, the center console, and the knobs on your radio. Automotive injection molding is perfect for this. It can create parts with different textures, from smooth and shiny to soft and leather-like. The parts made for the inside of a car also need to be strong and not rattle or squeak. A good mold ensures a perfect fit for all these interior components.

For exterior parts, the needs are different. These parts have to stand up to sunlight, rain, snow, and rocks kicked up from the road. For these, we use special types of plastic that are very durable and resistant to weather. Bumpers, body panels, mirror housings, and the black trim around your windows are often made with automotive injection molding. The mold for an exterior part has to be incredibly precise to make sure it lines up perfectly with the metal parts of the car. This manufacturing process helps make cars lighter, which can improve gas mileage.

This is a question I get all the time. People often see the mold as a big, upfront cost. And it can be. A complex mold can be expensive. But a smart mold design is one of the best ways to reduce your overall production cost. A good design makes the whole manufacturing process smoother and more efficient.

First, a well-designed mold can reduce the amount of plastic needed for each part. The design can include thin walls where possible, which saves material. While the thickness must be enough to keep the part strong, every bit of saved plastic adds up to big savings over a long production run. A good mold design also helps the part cool faster. A shorter cooling time means a shorter cycle time. This means you can make more parts per hour, which will lower your final cost per part.

Another way a good mold design saves money is by preventing problems. A bad design can lead to parts with flaws. These flawed parts have to be thrown away, which wastes material and time. A good mold will be designed to fill correctly every single time, leading to higher quality and less waste. This helps to reduce the overall cost. I always tell my clients: don’t cut corners on the mold design. A little extra investment here will pay for itself many times over. It’s a key part of making the automotive injection molding process truly cost-effective.

Choosing the right partner is critical. Not every company that does plastic injection can handle the high standards of the automotive market. The first thing I look for is experience. Has this company worked on automotive injection molding projects before? Do they understand the strict quality requirements? Ask to see examples of their work.

Next, look at their technology. Do they have modern, well-maintained machines? A good company invests in its equipment to ensure precision and efficiency. They should also have a strong engineering team. These are the people who will help you with your part design and your mold design. They can offer suggestions to improve your part and lower your cost. A good company acts as a partner, not just a supplier.

Finally, ask about their quality control system. How do they check the parts to make sure they meet the standard? They should have a clear process for inspection and testing. A good manufacturer will be happy to explain their quality process to you. Getting a quote is easy, but finding a company you can trust to deliver high-quality parts on time is what really matters. This is a big decision, so take your time and choose a company that feels right.

When we talk about traditional manufacturing for metal parts, we often think of cutting, stamping, or welding. Automotive injection molding is very different, and it offers some big advantages, especially for making complex shapes. Making a complicated part from metal might require several different steps and machines. With injection molding is used, you can often create that same complex part in a single step.

This leads to a much faster production process. As I mentioned, a single mold can produce a finished part in seconds. This speed helps to lower the cost of manufacturing, especially for large numbers of parts. Another big difference is weight. Plastic is much lighter than steel. By replacing metal parts with durable plastic ones, car makers can reduce the total weight of a vehicle. A lighter vehicle uses less fuel, which is better for the driver and the environment.

Of course, plastic isn’t right for every part. For major structural parts of the car’s frame, you still need the strength of steel. But for thousands of other components, from the wheel covers to the dashboard, automotive injection molding is the superior technique. It gives designers more freedom to create the shapes they want and helps the manufacturer control cost and increase efficiency. The technology has truly changed the way cars are made.

Even with all its benefits, working with an automotive mold has its challenges. The biggest one is the initial cost and time it takes to create the mold. A high-quality steel mold is a piece of precision engineering. It can take weeks or even months to design, build, and test. This upfront investment can be large, which is why this process is best for high-volume production.

Another challenge is getting the design of the mold perfect. If there is a mistake in the mold, it is very difficult and expensive to fix. This is why so much time is spent on computer-aided design (CAD) and simulation before any steel is cut. We run tests on the computer to see how the plastic will flow into the mold and where potential problems might be. This helps us fix the design of the mold before it’s made.

Finally, maintaining the mold is an ongoing task. A mold is a hardworking tool. Over thousands of cycles, it can start to wear down. The company responsible for the automotive injection molding must have a good maintenance program. This includes regular cleaning, inspection, and repair of the mold. A well-maintained mold will continue to produce high-quality parts for a long, long time. A special fixture might be needed to handle the mold during maintenance.

So, you have an idea for a part and you think automotive injection molding is the right process. How do you get a quote? The first step is to have a clear idea of your part. The best thing you can have is a 3D CAD file of your design. This file gives the manufacturer all the information they need about the size and shape of your part.

When you contact a company for a quote, they will ask for more than just the design. They will want to know what material you want to use. They will also ask how many parts you plan to make. The number of parts is very important because it helps them decide what kind of mold to build. A mold for 10,000 parts might be different from a mold for 1 million parts. The quote you receive will likely have two main costs: the one-time cost for the mold, and the per-part cost.

Don’t be afraid to ask questions when you get a quote. Ask what is included. Ask about the lead time for the mold and for production. I recommend getting a quote from a few different companies. This will give you a good idea of the current market price. But remember, the lowest quote is not always the best choice. Consider the company’s experience, quality, and service. This is the complete guide to what you know about automotive injection molding.

Uno stampo per apparecchiature originali (OE) viene utilizzato per realizzare parti per la casa automobilistica (l'OEM automobilistico) da installare su nuove auto in fabbrica. Uno stampo aftermarket viene utilizzato per realizzare parti di ricambio vendute nei negozi di ricambi auto. Lo standard di qualità per uno stampo OE è spesso molto più rigoroso.

A high-quality steel mold can last for a very long time. A mold built for high-volume production can often make over a million parts before it needs major repairs or replacement, as long as it is properly maintained. The type of plastic material used can also affect the life of the mold.

It is very difficult and costly to change a steel mold once it is finished. Small changes might be possible, but major changes usually require making a whole new mold. This is why the design phase is so important.