Lasciate che Istar vi aiuti a iniziare il vostro progetto con la nostra esperienza e il nostro know-how!

Caricate i file del vostro progetto e i requisiti di produzione e vi risponderemo entro 30 minuti!

Se ti sei mai chiesto come viene realizzata la custodia in metallo del tuo telefono o come le parti del motore di un'auto si adattano così perfettamente, questo articolo fa per te. Analizzeremo cosa sia una Macchina CNC , come funziona e perché è uno degli strumenti più importanti al mondo oggi. Vedrai come questa incredibile tecnologia delle macchine costruisce il mondo che ci circonda.

Cominciamo dalle basi. Cos'è una macchina CNC? Le lettere CNC stanno per Controllo Numerico Computerizzato. Pensala come a un robot super intelligente e forte. È una macchina che utilizza un computer per controllare ogni suo movimento. Invece di una persona che gira le ruote o preme i pulsanti sulla macchina, un programma per computer dice alla macchina esattamente cosa fare. Ciò consente un incredibile livello di precisione.

Questo controllo computerizzato è ciò che rende una macchina CNC così speciale. Il programma è un insieme di istruzioni, come una ricetta. Dice alla macchina dove muoversi, quanto velocemente andare e quale strumento utilizzare. Questo processo, chiamato lavorazione di precisione CNC, prende un blocco di materiale, come metallo o plastica, e lo taglia in una forma finita. Ogni parte che la macchina CNC realizza è quasi esattamente uguale a quella precedente. Questo è il motivo per cui una moderna macchina CNC è il cuore delle fabbriche di oggi. Questa macchina è davvero una meraviglia moderna.

L'intero percorso da un'idea a una parte finita è chiamato processo di lavorazione di precisione. Tutto inizia con un progetto. Innanzitutto, qualcuno crea un modello 3D della parte su un computer. Utilizzano un software speciale chiamato CAD, che sta per progettazione assistita da computer. Questo file CAD è come un progetto per la macchina. Ha tutti i dettagli della parte finale.

Successivamente, il file CAD passa a un altro programma chiamato CAM (produzione assistita da computer). Il software CAM trasforma il modello 3D in codice che la macchina CNC può leggere. Queste sono le istruzioni di produzione. Il codice dice all'utensile da taglio della macchina dove andare. Infine, un operatore inserisce un blocco di materiale, chiamato pezzo in lavorazione, nella macchina CNC. Eseguono il programma e la macchina inizia a tagliare. L'utensile della macchina segue perfettamente il codice per creare la parte lavorata. Questo processo di lavorazione che utilizza un computer è molto efficiente.

Non tutte le macchine CNC sono uguali. Esistono molti tipi di CNC di precisione, ciascuno costruito per lavori diversi. Queste macchine CNC di precisione sono strumenti straordinari per fare le cose. Le più comuni che vedrai nelle officine meccaniche sono frese e torni. Una macchina CNC può anche essere una taglierina al plasma, a taglierina lasero una taglierina a getto d'acqua. Ogni macchina è progettata per specifiche attività di lavorazione.

Ogni tipo di macchina di precisione ha uno scopo speciale. Ad esempio, un laser CNC può tagliare o incidere con un potente raggio di luce. Le taglierine al plasma CNC utilizzano un getto di gas caldo per tagliare il metallo spesso. Ci sono anche rettificatrici di precisione che creano superfici super lisce. Scegliere la macchina CNC giusta per un lavoro è molto importante. Dipende dal materiale che stai utilizzando e dalla forma che vuoi realizzare. Ogni macchina è uno strumento potente.

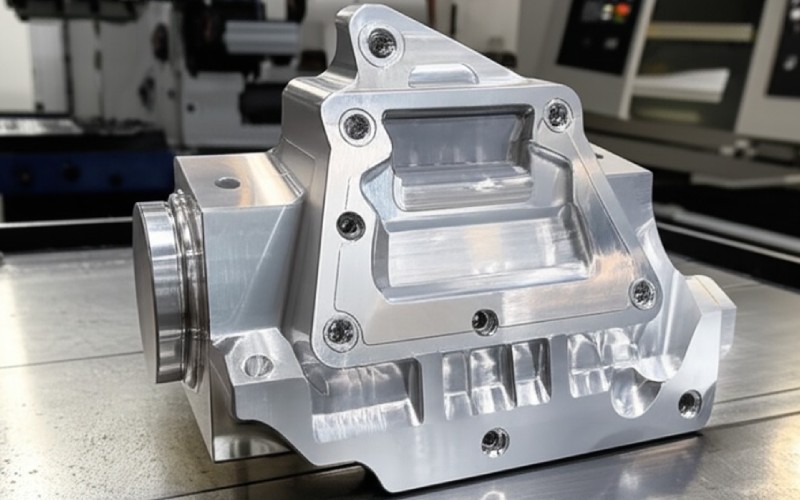

Quando le persone parlano di lavorazione di precisione CNC, spesso pensano a Fresatura CNC. Una fresatrice utilizza un utensile da taglio rotante per scheggiare materiale da un pezzo in lavorazione. Pensala come a un trapano molto preciso che può muoversi in molte direzioni. Il pezzo in lavorazione è tenuto fermo su un tavolo e l'utensile rotante si muove intorno ad esso, oppure a volte il tavolo muove il pezzo in lavorazione sotto l'utensile. Questo è un metodo di lavorazione chiave.

Le moderne fresatrici CNC sono molto avanzate. Alcune di esse, chiamate macchine CNC a 5 assi, possono muovere l'utensile e il pezzo in lavorazione contemporaneamente. Ciò consente alla macchina di creare forme molto complesse. Una macchina CNC a 5 assi può realizzare parti che sarebbero impossibili con una macchina più semplice. Questo è il motivo per cui le fresatrici CNC di precisione vengono utilizzate per realizzare di tutto, dalle custodie per telefoni alle parti per le astronavi. La fresatrice è un macchinario molto utile.

Sì, la fresatura non è l'unico gioco in città. Un altro metodo di lavorazione molto importante è Tornitura CNC. Questo viene fatto su una macchina chiamata tornio. Con un tornio, il pezzo in lavorazione gira molto velocemente. Un utensile da taglio non rotante viene quindi spostato contro la parte rotante per asportare materiale. Questo è perfetto per realizzare parti rotonde o a forma di cilindro, come viti, bulloni e alberi. Un tornio CNC funziona molto più velocemente di una persona che utilizza un tornio manuale.

Oltre alla tornitura, ci sono altri tipi speciali di lavorazione CNC. Per metalli molto duri o per forme piccole e dettagliate, utilizziamo la lavorazione a scarica elettrica (EDM). Questa è anche chiamata lavorazione a scintilla. Utilizza una scintilla elettrica da un elettrodo per fondere il materiale senza mai toccarlo. Ci sono anche taglierine laser CNC e getti d'acqua. Ogni operazione di lavorazione ha il suo posto nella produzione moderna. Abbiamo anche la foratura CNC, che utilizza un trapano per praticare fori con un posizionamento perfetto. L'utilizzo di un trapano in una macchina CNC è molto più preciso che farlo a mano.

Quindi perché ci prendiamo tutta questa briga? I vantaggi dell'alta precisione sono enormi. Il più grande è l'accuratezza. Una macchina CNC può realizzare parti con un'incredibile alta precisione. Può tagliare parti a dimensioni esatte, spesso entro pochi millesimi di mm. Questo è chiamato mantenimento di tolleranze strette. Ciò significa che le parti si incastrano perfettamente ogni volta. Ottieni precisione e qualità straordinarie.

Questo porta ad altri due grandi vantaggi: precisione e ripetibilità e precisione e coerenza. Una macchina CNC può realizzare migliaia di parti e ognuna sarà una copia perfetta. Non ci sono piccoli errori come quelli che potresti ottenere con i metodi di lavorazione convenzionali. Questo rende il processo di produzione più veloce ed economico a lungo termine. C'è meno spreco di parti difettose. Questo è il motivo per cui la lavorazione di alta precisione è così importante per realizzare prodotti affidabili.

Questa è un'ottima domanda. Con la macchina di precisione e il programma giusti, puoi realizzare quasi tutto. La lavorazione di precisione CNC viene utilizzata per creare parti complesse con dettagli intricati che sarebbero difficili da realizzare in qualsiasi altro modo. La macchina può tagliare, forare e modellare un blocco solido di metallo o plastica in una parte lavorata finale. Questa lavorazione prevede la rimozione di materiale per ottenere la forma desiderata.

Ovviamente, ci sono alcuni limiti. Alcune forme sono ancora molto difficili da lavorare. Ma una macchina CNC è perfetta per realizzare un prototipo. Un prototipo è una versione iniziale di una parte. Puoi progettare una parte, realizzare un prototipo su una macchina CNC e testarlo. Se hai bisogno di apportare modifiche, devi solo modificare il file CAD e realizzare un nuovo prototipo. Questo è molto più veloce dei vecchi metodi. Una volta che il prototipo è perfetto, la stessa macchina CNC può realizzarne altre migliaia.

Puoi trovare parti realizzate con la lavorazione di precisione CNC quasi ovunque. Le applicazioni della lavorazione cnc di precisione sono infinite. Il industria aerospaziale è un grande utente. Un singolo aereo ha milioni di parti e tutte devono combaciare perfettamente per la sicurezza. Utilizzando la lavorazione di precisione, il settore aerospaziale costruisce aerei affidabili. Anche l'industria automobilistica si affida ad essa per tutto, dai blocchi motore alle piccole staffe. La tua auto è piena di parti realizzate su una macchina CNC.

Altri grandi utenti includono il campo medico. Gli strumenti chirurgici e gli impianti devono essere perfetti. La lavorazione CNC di alta precisione lo rende possibile. Il mondo dell'elettronica lo utilizza per realizzare custodie per telefoni e laptop. L'esercito lo utilizza per armi e attrezzature. Qualsiasi settore che necessiti di parti robuste e affidabili realizzate in metallo o altri materiali utilizza servizi di lavorazione di precisione. Gli usi della lavorazione di precisione cnc sono in crescita ogni giorno. Questo tipo di processo di produzione è qui per restare.

Forse hai un'idea per una parte che vuoi realizzare. Iniziare un progetto di lavorazione è più facile di quanto pensi. Innanzitutto, hai bisogno di un progetto. Puoi imparare a utilizzare tu stesso il software CAD (progettazione assistita da computer) oppure puoi assumere un designer per creare un modello 3D per te. Questo modello è la chiave per l'intero processo. Verrà utilizzato per creare il tuo prototipo.

Una volta che hai il tuo file CAD, devi trovare qualcuno che realizzi la parte. Puoi cercare officine meccaniche locali che offrono lavorazioni di precisione affidabili. Hanno le attrezzature per la lavorazione di precisione CNC e gli esperti per aiutarti. Puoi inviare loro il tuo file e ti daranno un prezzo. Possono aiutarti a scegliere il materiale giusto e offrire consigli. Realizzare il tuo primo prototipo è un passo emozionante!

Il mondo della macchina di precisione è in continua evoluzione. Cosa riserva il futuro? Due grandi cose: ancora più precisione e più automazione. Nuovi Macchine CNC a 5 assi stanno rendendo possibile creare forme che potevamo solo sognare fino a pochi anni fa. Questa tecnologia ad alta precisione continuerà a migliorare. L'utensile della macchina di domani sarà ancora più intelligente.

L'automazione è l'altra grande tendenza. Stiamo già vedendo centri di lavoro in cui i robot caricano il pezzo in lavorazione sulla macchina e scaricano la parte finita. Presto, una sola persona potrà gestire un'intera stanza piena di macchine CNC da un computer. Questo renderà il processo di produzione ancora più veloce. Il futuro della macchina di precisione è luminoso. Continuerà a essere uno strumento chiave per costruire il nostro mondo, realizzando prodotti migliori per tutti noi. Questa macchina ha appena iniziato.