Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Have you ever wondered how a solid piece of metal can be pulled into a skinny wire? Or how it can be pressed into a very thin sheet like aluminum foil? It’s not magic. It’s because of two special abilities of metals: ductility and malleability. I have worked with many metals over the years. Understanding these features is very important for people who build and design things. It’s also great for anyone who is curious about how things are made. The words might sound alike, but the difference between ductility and malleability is big. Knowing this difference helps us pick the right metal for the right task. This article will explain these two qualities in a simple way. It will show you the key differences between ductility and malleability and tell you why they are so important.

From my own experience, the simplest way to picture ductility is to think about pulling something apart. Ductility is a material’s power to stretch when you pull on it without breaking. We call that pulling force tensile stress. When a metal has high ductility, it can be stretched into a new shape for good. For example, it can be made into a thin wire, and it will not snap.

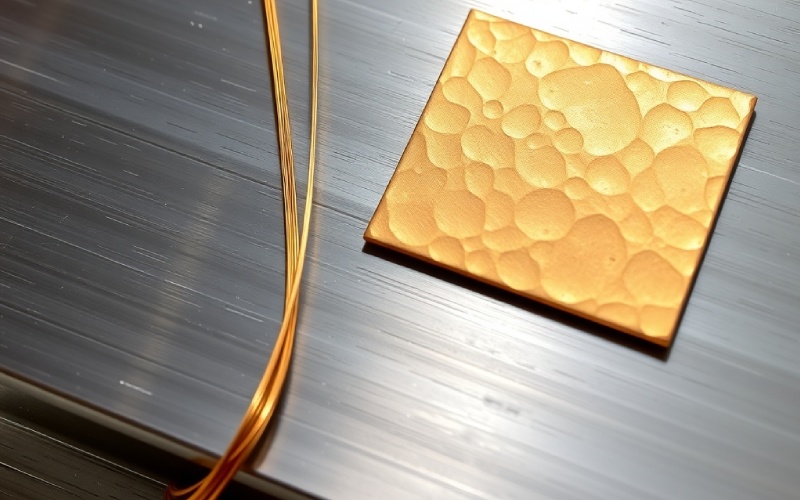

Just think about the copper wires inside the walls of your house. Copper is a metal that has a lot of ductility. This quality lets people make it into very long, skinny wires without the wire snapping. This power of a material to change its shape without breaking is what makes ductile metals so useful for many jobs. The quality of ductility allows a metal to be shaped in ways that a brittle material cannot handle. A brittle material would just break.

Now, let’s change our focus from pulling to pushing. Malleability is a material’s power to change shape when it is pushed on without breaking. That pushing force is called compressive stress. Think of it like hitting a metal with a hammer or rolling it flat. A malleable metal can be flattened into thin sheets, and it will not crack or break. Malleability is a very important quality that allows us to shape metals in special ways.

A great example that I like to use is gold. Gold is the most malleable metal that we know. You can take just one ounce of gold and hammer it into a very, very thin sheet that can cover a big space. Because it is so malleable, people use gold leaf for decorations. Another common example is the aluminum foil in your kitchen. Aluminum is a very malleable metal that can be rolled into thin sheets without breaking. Malleability lets us make everything from the outside parts of cars to soda cans.

I have found that the easiest way to remember the main difference between ductility and malleability is to think about the kind of force being used.

Here is a table to make the key differences between ductility and malleability very clear:

| Feature | Ductility | Malleability |

|---|---|---|

| Type of Force | Tensile Stress (Pulling/Stretching) | Compressive Stress (Pushing/Hammering) |

| Final Shape | Thin Wires | Thin Sheets |

| Common Example | Copper | Gold, Aluminum |

Understanding this basic difference between malleability and ductility is very important for engineers when they choose materials for a job. It is all about the type of force a material can handle and how we want to change its shape.

When I need to know the exact qualities of a metal for a job, we don’t just take a guess. We have special tests to measure ductility and malleability.

For measuring ductility, the usual way is a tensile test. In this test, a piece of the metal is pulled from both ends until it breaks. We measure how much the material stretched before it broke. This is called “percent elongation.” If the percentage is high, it means the metal has high ductility.

For malleability, testing is more about watching what happens. We can use compressive tests where a material is pressed, hammered, or rolled. We do this to see how much it can be flattened into thin sheets before it breaks. These tests don’t give us a simple number like ductility tests do. But they still give us a very good idea of how malleable a material is. We can also do a hardness test, which measures how well a material can stop from getting a dent. This can also give us hints about its malleability.

This is a good question that people often ask. Usually, if a metal is ductile, it is probably malleable too. Most metals, like aluminum and copper, are both ductile and malleable. This is because the tiny parts inside them, called atoms, can move around easily when you push or pull on the metal.

But it doesn’t always work the other way around. A malleable material is not always ductile. A good example is lead. Lead is a very malleable metal. You can easily hammer it into a thin sheet. But if you try to pull it into a wire, it will break pretty easily. This is because it has low ductility. So, you can have a malleable metal that is not very ductile.

In my job, I have used many ductile metals. Being able to be pulled into wires without breaking makes them very important for many kinds of work. Some of the most common examples of ductile metals are:

These metals that have a lot of ductility are very important in the world today. Ductility lets materials be made into tricky shapes. It also helps them handle pulling forces without failing.

Just like with ductility, there are several metals famous for being very malleable. Being able to be pressed into thin sheets is a useful quality for a malleable metal. Here are some examples of malleable metals:

Malleable metals like gold and aluminum can be shaped without hurting their structure. This is a very big plus when making things.

The jobs that need high ductility are all around us. They are very important for keeping us safe and making things work well. Ductility lets materials bend and change shape when a force is on them, instead of just breaking all at once. This is a very important safety feature in buildings and bridges. This is especially true in places where earthquakes happen. A building made with ductile metals will bend before it breaks. This gives people a warning.

Ductility is also very important for making things. The power to pull a metal into wires is key to the electronics industry. In the car industry, ductile metals are used to make car bodies. These bodies can crumple during a crash. This soaks up the force and keeps the people inside safe. Without the quality of ductility, many of the things we use every day just could not be made.

A malleable metal is needed for any job where a material has to be made into a flat or curved piece. Malleability is the power to do this without cracking. Think about the car industry again. Car bodies are made from big sheets of steel or aluminum. These sheets are pushed and pressed into the right shape. This is only possible because the metal has high malleability.

Other jobs for a malleable metal include:

The malleability of a metal lets us make a huge number of different things, from useful tools to pretty decorations.

I often get asked how ductility, malleability, and hardness are connected. Hardness tells you how well a material stops scratches or dents. In general, hardness and these other two qualities are usually opposites. This means that very hard materials are often easier to break. They are less ductile or malleable.

For example, a strong type of steel used to make a cutting tool will have low ductility. If you try to bend it, it will probably snap. On the other hand, a soft metal like pure aluminum has high ductility and malleability. But it has low hardness. Engineers often have to find the right mix of these qualities. Sometimes, a new metal mix, or alloy, is made to get the right combination. You might want it to be hard enough to last a long time, but also have enough ductility to stop it from breaking suddenly.

To finish up, here are the most important things to remember about ductility and malleability: