Lasciate che Istar vi aiuti a iniziare il vostro progetto con la nostra esperienza e il nostro know-how!

Caricate i file del vostro progetto e i requisiti di produzione e vi risponderemo entro 30 minuti!

The difference between feed rate and cutting speed is a very common mix-up. Many people believe they are the same thing. But they are not. Knowing the difference between feed rate and cutting speed is very important for getting good results.

This article is here to help you. I will explain it in simple words. You will learn what each term means. You will also learn why it is important for your CNC machine. When you finish reading, you will understand how to pick the right feed rates and cutting speeds. This will help you make better parts. It will make your cutting tool last longer. And it will make your machine work better and faster.

You can think of them as the heart of any machining operation. The wrong feed rates can break your cutting tool. They can also give you a bad surface finish. The wrong cutting speed can melt the cutting edge. It can also cause vibrations that will ruin your part. Getting your feed rates set up perfectly is a very big deal. To become a great machine operator, you need to understand the difference between them. The first step is to know the difference between feed rate and speed. The large number of feed rates you can choose from can make this difficult.

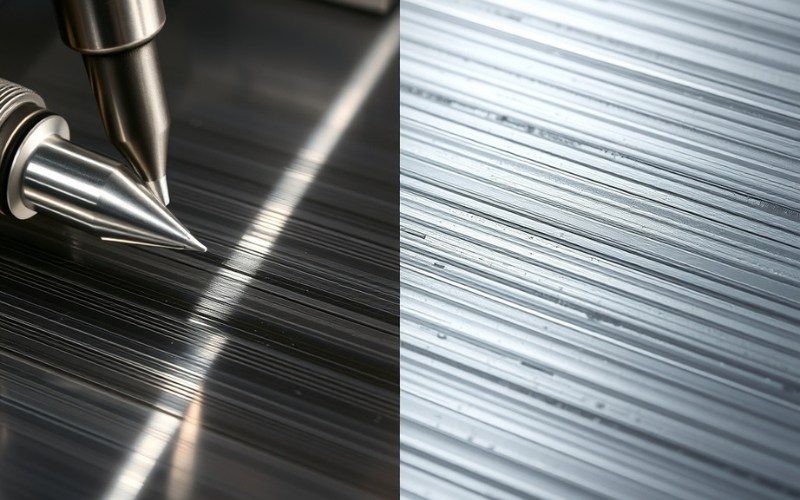

Let’s begin with cutting speed. It is not the same thing as how fast the CNC machine’s spindle spins. That is a mistake many people make. Cutting speed is about how fast the cutting tool’s edge moves. It is the speed it uses to travel across the material you are cutting. It is also known as surface speed. It is the speed difference between the moving cutting tool and the part being worked on. Imagine the cutting tool is a car and the material is a road. The cutting speed is how fast the car’s tire moves on the road’s surface.

Cutting speed is important. This is because it has a big impact on the cutting temperature. A higher cutting speed will make more heat. If there is too much heat, it can harm both the cutting tool and the workpiece. The cutting speed decides how long the tool will last. Different materials need different cutting speeds. For example, a hard material like steel will need a lower cutting speed. A soft material like aluminum can use a faster speed. You need to use slower cutting speeds for hard metals. Finding the right cutting speed in Lavorazione CNC is very important. The cutting speed is essential for a good result.

Now we can talk about feed rates. Cutting speed is about how fast the tool’s edge cuts. The feed rate is the speed that the cutting tool is pushed into the material. The feed rate is the distance the cutting tool moves for every full turn of the spindle. The spindle speed is simply how fast the tool is spinning. We measure it in revolutions per minute (RPM). The feed rate, however, is how fast that spinning tool moves forward, to the side, or down into the part.

The feed rate directly impacts how thick the chip of material is that your cutting tool removes. A higher feed rate will make a thicker chip. This leads to a faster material removal rate, which means you remove material faster. This can make your machining time shorter. But you need to be careful! Very high feed rates can put too much stress on your cutting tool. This can cause it to break. A slower feed rate makes a thinner chip. This is easier on the tool and usually gives you a better surface finish. Your CNC machine settings for feed rates are very important. Adjusting the feed rate is something you will do often. So, the difference between feed rate and spindle speed is simple. One is about spinning (spindle speed), and the other is about moving forward (feed rate). The feed rate also has a big impact on the cutting forces.

I believe that simple examples are the best way to learn. Let’s think about drilling a hole in a piece of wood. You are using a power drill.

With a CNC machine, you program these settings instead of doing it by hand. The CNC machine controls how fast the cutting tool moves compared to the workpiece. The difference between feed rate and cutting speed is like pushing the drill versus how fast the edge of the drill cuts. Knowing this difference between cutting speed and feed rate makes a huge difference. This will help you understand the difference completely. The feed rate vs cutting speed topic is just about two separate actions in the machining process.

Cutting speed and feed rates need to work together. You can’t set one and just forget about the other. The relationship between cutting speed and feed rate is like a partnership. A good machining process finds the correct balance between them. For example, a cutting tool that is made of a strong cutting tool material like carbide can usually handle higher cutting speeds. When you use a high cutting speed, you can often use higher feed rates too. This lets you finish the job more quickly.

But, if you use a high cutting speed and your feed rate is too slow, you might rub the cutting tool against the material. This is bad because it does not cut well. It makes a lot of heat and wears out the tool very fast. Also, if your feed rate is too high for your cutting speed, you can put too much work on the cutting tool and make it break. Finding the right balance between cutting speed and feed rates is very important for making your machine work well. You need to use the right feed rate and cutting speed for every single job on your CNC machine.

Finding the best cutting speed is very important for a few big reasons. First, it directly affects how long your cutting tool will last. If you run a tool too fast, it creates a high cutting temperature. This high heat will make the cutting edge dull very quickly. This means you have to spend more money buying new tools. A lower cutting speed is easier on the tool. It can make a cutting tool last much longer. Every cutting tool material has a recommended cutting speed range for cutting different types of material.

Second, the cutting speed is very important for the surface finish of your part. If the speed is too high, it can cause “built-up edge.” This is when small bits of the material get welded to the cutting tool. This gives you a rough finish. If the speed is too slow, it can cause “chatter marks.” The best cutting speed will give you a smooth and clean cut. Figuring out the cutting speed is not a guess. It is based on science and your own experience. The cutting speed is mainly affected by the material you are cutting and the cutting tool material. Softer materials allow for higher cutting speeds.

Here is a simple table. It shows how materials change the cutting speed you should use:

| Material Being Cut | Cutting Tool Material | Recommended Cutting Speed |

|---|---|---|

| Alluminio | Carburo | Alto |

| Acciaio dolce | Carburo | Medio |

| Acciaio inox | Carburo | Low to Medium |

| Titanio | Carburo | Basso |

As you can see, harder materials need slower cutting speeds. This helps manage the cutting temperature and tool life. Your CNC machine can get damaged if you use the wrong speeds. You should always stay within the recommended cutting speed for your tool and material.

Just like with cutting speed, finding the best feed rate is about finding a balance. The main goal when finding the best feed rate is to remove material as fast as you can. But you must do it without breaking the tool or getting a bad finish. The feed rate you can use depends on the strength of the cutting tool. It also depends on the power of your CNC machine. A strong, sturdy CNC machine and a tough cutting tool can handle higher feed rates.

When you are doing a “roughing cut,” your goal is to remove a lot of material quickly. For this, you will want to use higher feed rates. When you are doing a “finishing cut,” how good the surface looks is very important. For this, you will use slower feed rates to prevent marks. These marks, sometimes known as feed marks, happen when the cutting tool starts to cut the material. A slower feed will make these marks smaller. They will be closer together, which gives a smoother look. You need to change your feed rates for each machining operation. Hard materials may need slower feed rates to stop the tool from breaking. The feed rate in cnc machining is a setting you need to learn very well. Lower feed rates are often needed for work that has a lot of detail.

Many things can change the perfect feed rates and cutting speeds for a job. It is not the same for every situation. I tell people to think about these important things:

Thinking about all these things will help you pick the best feed rate and cutting speed. This is a very important part of any good cnc machining process.

This is a very good question. The answer is no. Every CNC machine has its own limits. The CNC machine itself is a big factor in what feed rates and speeds you are able to use. A smaller hobby CNC machine does not have the power or sturdiness to handle fast feed rates. A large industrial machine can handle much more.

The machine’s top spindle speed will limit your highest cutting speed. This is especially true when you use small tools. The power of the spindle motor decides how much cutting force the machine can handle. This then limits your material removal rate. It is a bad idea to push a CNC machine past its limits. It can lead to the machine not cutting in the right place. It can also lead to broken tools, and even damage to the machine itself. You must know your CNC machine. You need to know what it can and can’t do when you are setting your feed rates and cutting speed and feed rate.

Let’s look at a simple machining operation on a CNC machine. Let’s say we need to cut a pocket into a block of aluminum. We will use a 1/2-inch carbide end mill.

I know this was a lot of information. But if you can remember these main points, you will be on your way to getting very good at using your CNC machine.