Lasciate che Istar vi aiuti a iniziare il vostro progetto con la nostra esperienza e il nostro know-how!

Caricate i file del vostro progetto e i requisiti di produzione e vi risponderemo entro 30 minuti!

Most failed parts do not break into two pieces. Instead, they fail because they bend, flex, or change shape too much. They are just not stiff enough. This article is my guide to help you not make that common mistake. We will look at how to design for stiffness. We will do this by picking the right material properties and part shape. If you have ever made a part that felt weak or bent when you put weight on it, this article is for you. I will show you the simple ideas you can use to make a stronger and stiffer part.

Let’s begin with the simple things. What is stiffness? To put it simply, stiffness is a way to measure how much a part fights against bending or changing shape when you push or pull on it. This push or pull is called a load. Think about a plastic ruler. When you push on it, it bends. How much it bends from that load shows you how stiff it is. A really stiff part will hardly move at all. A bendy part will show a lot of deformation.

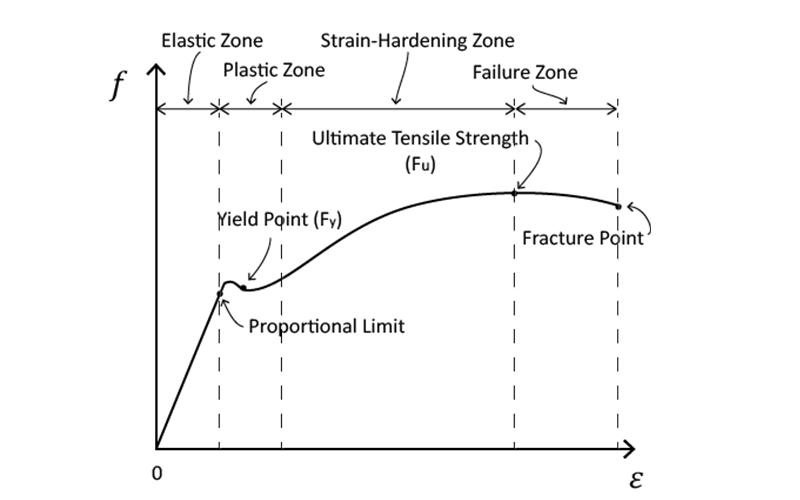

It’s very important to know that stiffness is not the same thing as strength. Strength, or yield strength, tells you how much load a part can handle before it breaks. Or before it bends and stays bent. Stiffness is about temporary bending that goes back to normal. This is called elastic deformation. A stiff part does not want to do this kind of deformation. A part can be very strong but not very stiff. Think of a steel cable. It can hold a very heavy load without breaking (that’s high strength). But it is not stiff at all. When we design for stiffness, our main goal is to stop or lessen this unwanted shape-changing when a load is on the part.

I have learned that for many jobs, stiffness is very important. Think about a bookshelf. You want it to hold your books without bending down in the middle. The shelf does not need to be strong enough to hold a car. But it needs enough part stiffness to handle the load of the books without a lot of deflection. If it bends down, it’s not working right, even though it’s not broken. This is a problem with stiffness, not a problem with strength.

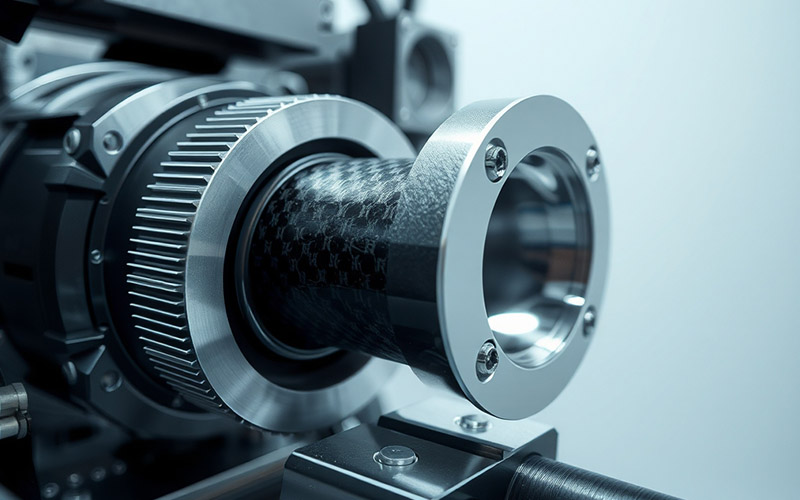

This idea is true for many things. In a car’s frame, high stiffness is needed so the car drives well and the structure is safe. In a Lavorazione CNC tool, the structure must be extremely stiff so it can make very exact cuts. If the cutting tool moves just a little bit from the load, the part being made will be wrong. When you put a load on a component, it is super important that it keeps its shape. If you forget about stiffness, your part might not work well, or it might fail completely. The structure will deform and might not do its job with its normal load.

So, how can we find out how stiff a material is by itself? We use a special number for this. It is called the Modulus of Elasticity. It is also known as Young’s Modulus. I know it might sound hard, but the idea is easy. The elastic modulus is a number that tells you how stiff a material is. A bigger number for the elastic modulus means the material is more stiff. This is one of the most important material properties we look at.

To make it clear, let’s look at the modulus for a few materials that people often use. The modulus is usually measured in pounds per square inch, or PSI. A bigger number means it is harder to make it change shape.

| Materiale | Elastic Modulus (Approx. PSI) | Note |

|---|---|---|

| Acciaio | 30,000,000 psi | Super stiff. People use it a lot for a structure that needs to have high stiffness. |

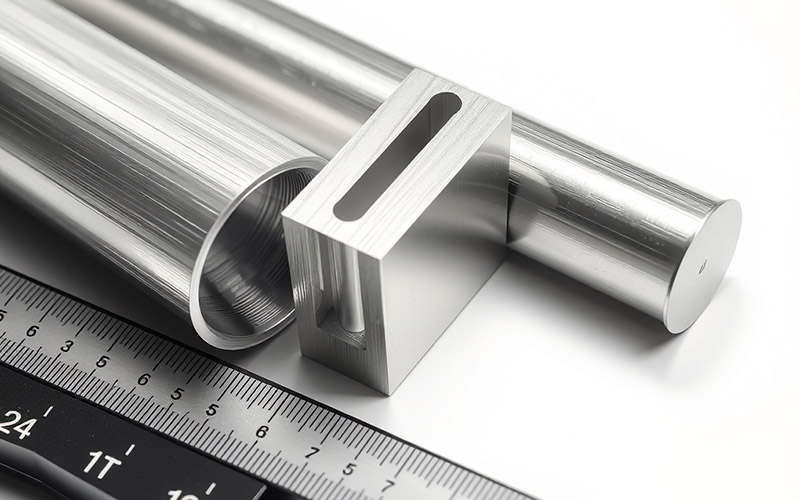

| Alluminio | 10,000,000 psi | It is not as stiff as steel, but it weighs a lot less. |

| Nylon caricato a vetro | 1,200,000 psi | A plastic often used in an injection mold. It’s stiffer than regular nylon. |

| Nylon (Unfilled) | 400,000 psi | Bendy. A small modulus means it changes shape easily when you put a load on it. |

As you can see, the difference is very big! The modulus for steel is much higher than the modulus for nylon. This means if you have the same shape and the same load, a steel part will bend much less than a nylon part. The modulus of elasticity is a very important property you have to think about.

The first and easiest way to make a part stiffer is by picking the right material. This is called material selection. If your design needs to have high stiffness, you should begin by looking for materials with a high elastic modulus. Using a material with a bigger modulus is often the simplest way to increase the stiffness of a component. For instance, if a part made from an aluminum alloy is too bendy, changing to steel will, right away, make it about three times stiffer.

The choice you make changes everything. If you need a part that is light but also very stiff, you could look at something like a carbon fiber composite. Carbon fiber has a very high modulus for how little it weighs. But it also costs a lot of money. If you are making a simple part with an injection mold, you could pick a glass-filled nylon instead of a normal nylon to get that increased stiffness. The material properties you pick are like the building blocks for your design. Picking the wrong material can cause a big problem that’s tough to fix later on. We have to figure out what we need first to choose the right material.

With so many materials available, how do you pick one? A long time ago, I used to spend many hours looking in big, thick books. Now, we are lucky to have helpful tools. A material selection assistant is a kind of computer program that helps an engineer find the best material for a task. You can tell the program what material properties you are looking for.

For example, you can tell the material selection assistant, “I need a material for a part from an injection mold. It needs a modulus of elasticity over 1,000,000 PSI, and a yield strength of at least 8,000 PSI.” The program will then show you a list of plastics, like a glass-filled nylon, that fit your needs. It saves a lot of time. It also helps you find new materials you did not know about. It helps you find the very best material to not change shape under a certain load.

This next part is my favorite. The material you use is only part of the answer. The other part is the shape of the object! The “stiffness of shape” is explained by something called the moment of inertia. This is a very basic and important idea. Let me show you what I mean. Take a ruler and put it flat across two books. Push down on the middle. It bends easily, doesn’t it? Now, stand the ruler up on its skinny edge and push down with the same load. It is a lot harder to make it bend.

This shows how the moment of inertia works. The ruler is made of the same material (so it has the same elastic modulus). It has the same amount of material in both setups. But the shape and the way it is turned toward the load have changed. A shape that is tall and thin is much stiffer than one that is short and wide when the load pushes downward. The formula for the moment of inertia of a simple rectangle shows that the height is very important. This means if you double the height of a beam along the axis of the load, it becomes eight times stiffer! This is a great way to improve part stiffness, and you don’t have to add a lot of weight.

Now, let’s bring these ideas together. How stiff a part ends up being comes from two things: the material’s elastic modulus and the part’s moment of inertia. How much a part bends under a load has a direct link to these two things. A simple way to understand this is a rule of thumb: a part’s stiffness is directly tied to its modulus multiplied by its moment of inertia. To make something bend less, you can make either one of those bigger.

If you have a beam with a load on it, you have two ways to make it stiffer. First, you can use a material with a higher modulus. For example, you can change from plastic to steel. Second, you can change the shape and size of the beam to make its moment of inertia bigger. For example, you can make the beam deeper. A good engineer uses both of these ideas to make a design better. They change the structure to get the best results for the lowest cost and weight. It is usually cheaper to change the shape than to use a material that costs more money, like a carbon alloy.

For parts with tricky shapes, it is hard to figure out the bending and stress just by doing math. This is when we use a strong computer tool called Finite Element Analysis, or FEA. I use FEA very often to check my designs. With FEA, an engineer can make a 3D model of a component on the computer. Then, the engineer can test it on the computer before making a real one.

In an FEA study, you put a load on the computer model. The FEA program then figures out how the structure will change its shape. It also shows you the areas with high stress. The result is usually a picture with colors. For example, red might show high stress or a lot of deflection, and blue might show low stress. This is a great way to “see” what your part will do. You can use an FEA study to quickly try out different materials and shapes. An FEA tool is a key part of making a complex structure better and reducing strain. It is a very important part of modern design for stiffness.

Let’s pretend we are making a plastic bracket using an injection mold process. The bracket is meant to hold a small shelf. The first one we made, using standard nylon, bends down too much when we put a load on it. The deflection is too big. What should we do? We use the ideas we have talked about.

First, let’s look at our material selection. Our normal nylon has a low modulus. We can change to a glass-filled nylon. This material has a much higher elastic modulus. This will make the component more stiff. Second, let’s change the shape to make the moment of inertia better. We can add thin walls, called ribs, to the bracket. Ribs make the part deeper and stiffer along the axis of the load, but they do not use much more material. Third, we can do a fast FEA study. We can model both the new material and the new ribs in our FEA program. We apply the same load, and the FEA output will show us the new, smaller deflection. This FEA process helps us make sure our design is good before we spend money on a new injection mold.

How do we know when our design is ready? Our aim is to find the very best design. This means a design that is stiff enough, but also costs as little as possible and weighs as little as possible. To figure this out, you have to first set your goal. For the shelf bracket, our goal could be: “The bracket cannot bend more than 0.1 inches when a 20 lbf load is on it.”

Once we have this clear goal, we can use FEA to try different ideas.

We can run an FEA for each idea. For each design, we figure out how well it works and how much it costs. The best design is the one that hits our 0.1-inch bending target and costs the least. It is an engineer’s job to find a good mix between these things. Using FEA helps us choose wisely based on good information. It helps us make a structure that can handle the load it is meant to carry. This is what good engineering and good design for stiffness are all about.

Here are the most important things I’ve learned about designing for stiffness using material properties.