Lasciate che Istar vi aiuti a iniziare il vostro progetto con la nostra esperienza e il nostro know-how!

Caricate i file del vostro progetto e i requisiti di produzione e vi risponderemo entro 30 minuti!

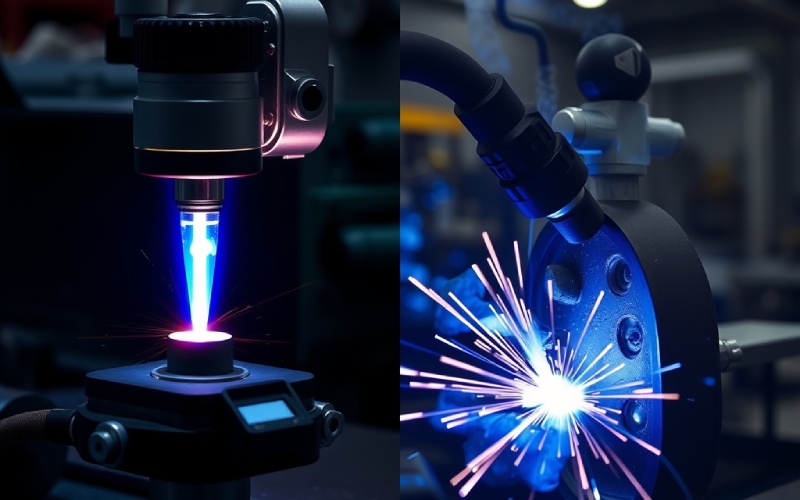

You will often hear about two big names: laser welding and MIG welding. When you first look at them, you see they both join metal pieces together. But the way they do it, and the kind of results you get, are very different. Making a choice between laser welding vs MIG welding is a very important one. This choice affects the strength of your joint, how it looks, and how much time and money you spend. This article will tell you about my time using both of these great ways to weld. It will help you see which one is the perfect choice for the thing you are building.

Let’s begin with a very common method: Metal Inert Gas, or MIG welding. I still remember my first time holding a MIG welding gun. It felt strong and simple to use. The MIG welding process is a kind of arc welding. It uses a metal wire that comes out of the welding gun without stopping. This wire goes into the spot you are welding, which is called the weld pool. An electric arc is made when this wire touches the metal part you are working on. This arc is very, very hot. It melts the wire and the main metal parts. Then, they all mix together. When it all gets cold, it makes a strong joint.

A special gas flows out of the welding gun, too. This is called a shielding gas. It protects the hot, melted weld pool from getting messed up by the air around it. This is why it has “Inert Gas” in its name. This way of welding can be used for many things. It is also known for being fast and pretty easy to learn. That is why so many metal workshops and people who like to build things at home use it. You can see MIG welding used for all sorts of jobs. These jobs include fixing car frames and exhaust systems. They also include building metal gates or making art and sculptures.

The whole welding machine is made up of a few parts. There is a power source and a wire feeder that pushes the wire out. There is also the welding gun and a big tank of shielding gas. This machine is a real workhorse when it comes to making things with metal. One of the best things about it is how fast it is. The wire feeds out on its own. This means you can make long, even weld beads without having to stop. This really helps you get more work done faster.

Now, let’s talk about the more modern side of welding. Laser welding seems like it came from a space movie. This method does not use an electric arc. Instead, it uses a laser beam that is pointed at a very small spot. This laser beam is used as the heat source. You can think of it like using a magnifying glass to point sunlight at one spot. But it is much, much more powerful and exact. This focused laser beam makes a lot of heat right on the joint. It melts the materials so they can join together.

One thing I find really neat about laser welding is that it is a non-contact process. This means the laser welding machine does not actually touch the metal piece. This, along with the very small and exact point of heat, gives you a very clean weld. It has very little effect on the metal around it. A lot of the time, you don’t even need to add any filler material. The main metal parts just melt and join together on their own. There are two main ways laser welding works. One is conduction welding, which is for thin metals where you only need to melt the top. The other is keyhole welding. It uses a stronger laser to make a deep, thin hole. This lets the weld go very deep into thicker metal.

Because it is so exact, laser welding is perfect for parts that need careful handling and for jobs that use new technology. It has totally changed industries like aerospace, medical, and electronics. In these fields, the weld quality must be perfect every single time.

When you look closely, the main difference between laser welding and MIG welding is the heat source. MIG welding uses an electric arc. This arc is strong, but it also spreads out and covers a bigger area. This makes a larger weld pool. It also creates a larger heat-affected zone (HAZ). The HAZ is the spot around the weld that got hot but did not melt. The heat can change the way the metal is. Sometimes this can make the metal weaker or cause it to bend out of shape. The heat input from MIG welding is pretty high.

Laser welding, on the other hand, uses a focused laser beam. This gives you a heat source that is focused on one tiny spot. The heat input is very small and can be controlled with great accuracy. This leads to a much smaller heat-affected zone. I have seen tiny electronic parts get welded with a laser. They were right next to other sensitive parts that were not damaged at all. This low heat input is a very big plus. It causes less bending or twisting and puts less stress on the final piece. For jobs that need very exact measurements and very little bending, laser welding is the clear winner.

Yes, for sure. If you need a very accurate weld, you should choose laser welding. The amount of control you have with a laser is better than any of the older welding methods. The laser beam can be pointed at a super small spot. Because of this, you can make very small, clean, and exact welds. This greater precision is very important when you work with thin metals. It is also important for designs with a lot of small details.

Think about making things like medical devices such as implants or surgical instruments. The welds on these things must be perfect. They need to have smooth weld beads and no flaws or mistakes. Laser welding creates these nice, high-quality welded joints very easily. MIG welding is great for a lot of jobs, but it just can’t match this level of skill and care. The electric arc is not as focused. This leads to wider weld beads and a weld pool that is harder to control. For big building jobs where you join thick pieces of carbon steel, MIG’s wider weld is great. But for delicate parts where every tiny detail is important, you must have the precision of laser welding.

Both welding processes can handle many types of materials. But, there are some big differences you should know.

MIG welding is usually:

Laser welding gives you:

Here is an easy table to show the differences:

| Caratteristica | Saldatura MIG | Saldatura laser |

|---|---|---|

| Materiali comuni | Steel, Stainless Steel, Aluminum | Steel, Stainless Steel, Aluminum, Titanium, Nickel Alloys, Copper |

| Spessore del materiale | Good for many sizes, especially thicker metal | Works great for thin to medium-thick metal |

| Different Metals | Can be hard, needs special skills | Works great for joining two different kinds of metal |

The uses for these two welding methods really show what they are good at. Because MIG welding can be used for so many things and you get a lot for your money, you see it everywhere.

Laser welding is used in places where being exact and using low heat is very important. It is a high-tech tool for high-tech industries.

When you ask about speed, the answer changes based on the job. For a lot of factory lines that make many items, laser welding is a lot faster. A laser welding machine, especially one that is set to run by itself, can move along a joint very quickly. It can often be up to ten times faster than MIG welding when working on thin materials. This speed is a big reason why companies that want to automate their welding are using fiber lasers and other laser welding equipment.

MIG welding is also very fast when you compare it to other old ways of welding, like TIG. The semi-automatic kind, where the wire comes out on its own but a person holds the gun, is quick. The wire feeds without stopping, so you do not have to pause to change welding rods. In a big metal workshop that works on thick steel plates, how fast MIG welding can put down metal can be better than using a laser. So, while laser welding often wins the speed race, MIG welding is still a very good way to get a lot of work done.

I get asked this big question all the time. The simple answer is yes. The cost to buy laser welding equipment at the start is much higher than a MIG welding machine. We are talking about a big investment of money. The technology inside a laser welder is very complex and costs a lot to make. This includes the laser part itself and the special lenses.

But that is not the whole story. If you look at the final cost for each weld you make, laser welding can save you money in the long run. Here is how:

It’s cheaper to get started with MIG welding. The welding machine, wire, and gas are not too expensive. This makes it a good choice for smaller shops and people working at home. So, while MIG is cheaper to start with, laser welding can give you more value for your money over time in places that make a lot of things and need high quality.

For someone who is new to welding, MIG welding is one of the easiest ways to learn. I have taught people the basics of it in just one afternoon. The method is simple and easy to understand. You just pull the trigger on the welding gun. The machine takes care of the wire speed and the arc. The main skill you need to learn is how to move the gun at a steady speed and the right angle.

Laser welding needs more special knowledge to get it set up. You have to understand the laser settings, like power, focus, and speed, to make a good weld. But, after the welding machine is programmed, it is very easy to run. This is especially true when it is set up to automate the work. The process can be done the same way every time and you can count on it to be the same. That is why it is so good for automation. You can set up a laser to do the same perfect weld thousands of times. MIG welding can also be automated. But because laser welding does not touch the metal and is so exact, it is a simpler and more reliable process to automate.

After working with both of these welding methods for years, I know the best choice depends on what your job needs. You need to ask yourself some important questions.

Both MIG and laser welding are great ways to join metal. They just are good at different things. MIG is the tool that can do many things and is very powerful. Laser welding is the tool that is very exact and works at high speeds. When you understand what makes them different, you can feel good about picking the right one to make your project a success.