Lasciate che Istar vi aiuti a iniziare il vostro progetto con la nostra esperienza e il nostro know-how!

Caricate i file del vostro progetto e i requisiti di produzione e vi risponderemo entro 30 minuti!

In my job, I have seen how a secret force can make a design work or fail. That force is shear stress. It is a very interesting and strong kind of stress that is all around us. You may not be able to see it, but shear stresses are working in everything. They are in a pair of scissors and even in the blood moving in your body. You should read this article. I am going to explain what shear stresses are in a simple way. I will help you learn this main idea from the study of physics and building things. We will see how a force is applied and how that makes shear. You can forget the hard books. I am here to give you the simple facts about shear stress.

So, what is this unseen force I am talking about? Think about a thick book. If you push straight down on the top cover, you are using a normal stress. But what if you put your hand flat on the cover and push it to the side? The book will change its shape, and the pages will move against each other. That sliding force is the main idea for understanding shear. The shear stress is the force per unit area you are using to push sideways. The stress definition for shear is a force applied that is even with a surface.

The shear stress is a force that tries to make one part of an object slide over another part. This shear stress happens when a force acts on a surface. Think about the book’s pages pushing back against this sliding. That is where shear stresses begin. The stress is spread over the whole area of the page. This stress is a type of force that can cause a big change in shape, or deformation. The force per unit area is an easy way to think of it. The resulting shear stress is the thing that we measure. This kind of stress is very normal.

When we talk about shear stresses, we are talking about this push-back from the inside. Every material has it. The force exerted on the book cover makes internal forces inside the paper. The shear stress is the force that acts on the inside. So, shear stress is mostly a reaction on the inside to a push or pull from the outside. The shear stress is the amount of this inside force per unit area. It is a big idea for knowing how things stay together or fall apart due to shear.

In my work, I have had to explain the different kinds of stress many times. It is easy to mix them up. The big difference is the direction of the force. Think of a tall post holding up a roof. The roof pushes straight down on the post. This makes a compressive stress. This is because the force is applied perpendicular to the top of the post. If you pulled on a rope, you would make a tensile stress. This is also a force applied perpendicular to a slice of the rope.

Shear stress is not like that. With shear, the force is not perpendicular. The applied force is even with the surface it acts on. Let’s think about our book again. Your hand pushed sideways, even with the cover. This is a great example of shear. This is not a bending stress. Another good example is a pair of scissors. Each blade pushes on the paper. But they push in opposite ways on a very small spot. This makes a very high level of shear stress. That high stress cuts the paper.

So, the main thing to remember is the direction. If the stress is applied by a force pushing or pulling straight on, it is a normal stress. If the stress is from a force trying to make layers of a material slide apart, you are working with shear stresses. A beam can have both bending stress and beam shear. Knowing the difference is very important when you build anything, from a bridge to a shelf. Many things that break is shear stress.

Now, you might be thinking, “This is good, Robert, but how do we give it a number?” I am happy you asked. We can calculate shear with a very easy formula. The main shear stress formula is one of the first things people learn in engineering. It is not hard to remember.

Shear Stress (τ) = Force (F) / Area (A)

Let’s look at what this formula means.

So, the shear stress formula tells us that shear stress is the force divided by the area. The shear stress can be calculated using this simple formula. This formula is the starting point for knowing shear. The formula is used a lot. The units of shear stress we use are also important. The normal unit for shear stress is the Pascal (Pa). One Pascal is the same as one Newton of force per square meter. So, you will often see shear stress units written as pascals or newtons per square meter (N/m²). This simple formula is very useful. It lets us guess how a material will act when a shear force is put on it. We use this formula often.

This formula shows us something important. There are two ways to make the shear stress bigger. You can make the force bigger, or you can make the area smaller. This is why a sharp knife cuts so well. The force from your hand is put on a very small area (the edge of the blade). This makes a very high shear stress that is strong enough to cut a tomato. The stress can be calculated using this big idea. This formula is very important for making parts that are designed to withstand certain forces. You can use this formula to infer shear stress in many places.

Yes, I can! Shear stress is all around you. After you know what to look for, you will see it often. Here are some normal examples of shear stress I have seen in my work and in my life.

These examples of shear stress show how normal this type of stress is. It is a main force that builders and science workers must know about and plan for. The shear stress experienced by materials in these situations can be very, very large.

The main idea of shear is always about a sliding force. But there are a few special cases or type of shear stress that have their own names. This helps us be more clear in our jobs. I have worked with all of these, and it is good to know what makes them different.

Here is a table to explain each main type of shear stress:

| Type of Shear Stress | Che cos'è | Where You Find It |

|---|---|---|

| Taglio diretto | This is the easiest type of shear stress. It happens when a force is used to make one part slide over another part directly. | Cutting with a scissor, a bolt that holds two plates. |

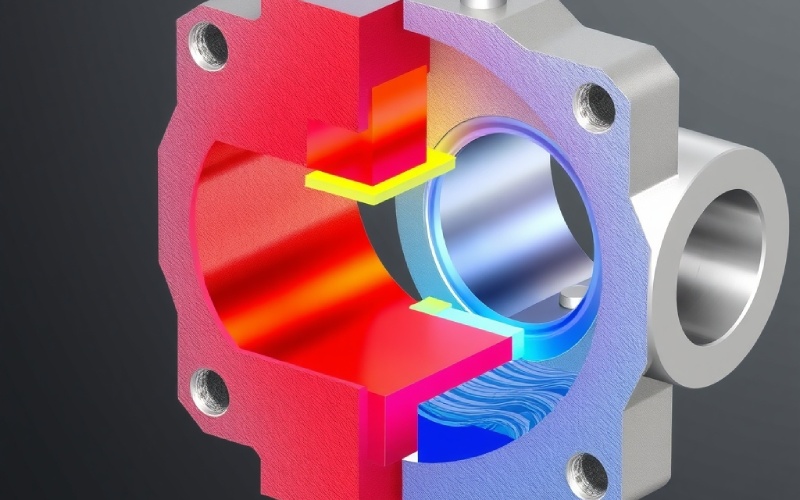

| Torsional Shear Stress | This type of stress happens when you twist something. Think about twisting a wet towel to get water out. You are using a twisting force. This makes torsional shear stress inside the towel. | A moving rod in a car, a tool turning a bolt. |

| Beam Shear Stress | As we talked about, this happens in a beam when there is weight on it. The stress comes from the weight trying to cut the beam up and down. It is a big part of beam shear. | Shelves, bridges, floor supports. |

| Wall Shear Stress | This is a special type of shear stress. It happens when a fluid (like air or water) moves over a hard surface. The fluid right on the wall does not move. The fluid farther away moves faster. This speed difference makes a rubbing or shear feeling on the wall. We often have to measure the wall shear stress. | Wind on a house, water in a pipe, blood flow in a person’s body. |

Each type of shear stress is figured out with a slightly different formula. But they all come from the same main rule: a force making layers slide. Knowing the special type of shear stress is very important for guessing how an object will act when a force is applied. The shear stress is proportional to the force in most situations.

This is where I find things get very interesting. Shear stress in hard things is about changing shape and breaking. But in a fluid, shear stress is about moving. When you use shear on a hard thing, it will change its shape a little and then stop. But if you keep putting shear stress on a fluid, it will keep changing its shape. In other words, it will flow.

This happens because the small parts in a fluid are not held in one spot like they are in a hard thing. A fluid cannot fight a shear stress by not moving. The shear stress makes the fluid move. The word for how much a fluid fights against this shear flow is viscosity. Think about honey and water. Honey has a high viscosity. So, it fights against flowing more than water does. This means it can take a higher shear stress for the same amount of flow. The stress exerted by the fluid has to do with its viscosity.

In the study of fluids, we often talk about Newtonian fluids and non-Newtonian fluids. Newtonian fluids, like water or air, are simple. For them, the shear stress changes directly with the shear rate. The shear rate is how fast the layers of the fluid are sliding by each other. The viscosity does not change. But for non-Newtonian fluids, like ketchup or paint, the viscosity can change. The shear stress might make them flow easier or harder. The study of fluid flow is all about knowing how a fluid acts when it feels shear stresses.

In my work, you cannot talk about stress and not talk about strain. They are like two parts of a whole. The link between stress and strain is a very basic and important part of knowing how materials act when a force is applied. It is really simple: stress is what you do to an object, and strain is how the object changes.

Stress, as we have said, is the force per unit area inside a material. It is the inside force fighting the outside force. Shear stress is the special type of stress from a sliding force. So, what is strain? Strain is how we measure the deformation, or the change in shape, of the material. For shear, we talk about shear strain. Shear strain tells us how much the material has changed its shape from what it was. This change is because of the shear stress.

Think about our book again. The shear stress is the force from your hand spread over the book cover. The shear strain is the new angle of the side of the book. A stronger push (more shear stress) will make it lean more (more shear strain). For most materials, this link is straight and even up to a point. We call this being elastic. The stress and shear are directly linked to the strain. This link helps us guess how a material will change its shape when we use a shear force.

Every material feels shear stress when the right force is applied. This is true for a hard steel beam or a moving fluid like water. But how they feel it is not the same. How a material is built on the inside decides how it will act to the shear stress that is applied parallel to its surface. The shear stress experienced by materials is a very important thing for how we use them.

For hard things, shear stress makes layers of tiny atoms slide over each other. If the shear stress is not very high, the material might just change shape in an elastic way. This means it will go back to its old shape when the stress is taken away. But if the shear stress levels go too high, the deformation can be forever. The material could also break all the way. Think of a metal bolt being cut off. The maximum shear stress was too much for it. Different materials are designed to withstand different shear stress levels.

For a fluid, the feeling is a constant moving. A fluid, because of what it is, cannot hold a still shear stress. The shear stress in a fluid has to do with its viscosity and the shear rate. The force exerted by a moving fluid on a surface is called wall shear stress. It comes from the rubbing between the fluid layers. This is very important for things moving through the air and even for blood flow. The wall shear stress on the inside of blood vessels is an important sign of health. A higher shear rate means there is more stress.

This is a very important question for any builder or designer. A level of shear stress gets dangerous when it is more than the material’s shear strength. Every material has a limit. It is a point where it will fail when subjected to force. This limit is its maximum shear stress. If the shear stress in a part gets to this number, it will break. My job is to make sure that does not happen.

For example, when making a bridge, builders must figure out the maximum shear stress that the bolts and beams will feel. This comes from cars, wind, and the weight of the bridge itself. Then, they pick materials and sizes that can handle much more than that figured stress. This is known as a safety factor. A high level of shear stress can cause a very big and bad break. We need to know the shear stress levels our parts can take.

The danger is not always a fast break. Sometimes, feeling a lower shear stress over and over again can make a part fail over time. Think of bending a paperclip back and forth. You are using shear stress each time, and after a while, it breaks. In fluids, high shear stress can be bad, too. In a pipe, high wall shear stress can make more rubbing. This means more power is needed to move the fluid. It can also wear away the inside of the pipe over time. So, watching shear stress levels is all about making things safe and long-lasting.

It always begins with a force from the outside, or an external force. You cannot have stress if there is no force. But how does that outside force make the inside shear stress? The main idea is that the force acts in a way that tries to make parts of an object slide. The shear stress can also be made by a force that is not direct.

Let’s look at a simple beam one more time. Think of a wood plank on two supports. If you stand in the middle, your weight is the external force pushing down. This force goes through the plank to the supports. Now, think about a straight up-and-down slice of the plank right by one of the supports. The support is pushing up on one side of the slice. The weight on the other part of the plank is pushing down on the other side. This makes an up-and-down shear force inside that surface.

This inside shear force, spread over the area of the beam’s slice, is what we call beam shear stress. The external force (your weight) is what made it happen. The force starts a line of internal forces inside the material as it fights being cut or made to make a material change its shape. The shear stress may be the most important thing to look at. So, at any time a force is applied in a way that makes sliding happen, you will get shear stress. It is a direct reaction to that external force. The shear stress is applied on the inside as a reaction.