이스타르의 경험과 노하우를 바탕으로 여러분의 프로젝트를 시작할 수 있도록 도와드리겠습니다!

디자인 파일과 제작 요구 사항을 업로드하시면 30분 이내에 답변해 드리겠습니다!

There are many kinds of holes in many kinds of materials. Two types of holes that often mix people up are the countersink and the counterbore. They might sound the same, but they are very different from each other. Knowing this difference is a very important thing for any job. This article will show you these differences in an easy way. You will find out what each hole is, when to use it, and why it is important. This will help you make your work look good and be done right.

A countersink is a certain type of hole. I can still recall the first time I needed to create one. I had a screw that needed to be completely even with the surface. A normal hole would not do the job. The top of the screw would stick out. A countersink hole fixes this problem. It is a hole shaped like a cone that you drill at the top of a smaller hole, called a pilot hole. This cone shape is a perfect fit for the shape of a countersink screw head. The angle of the countersink is a very important detail. It must be the same as the angle of the fastener. This way, the fastener can sit flat with the surface of the material. A fastener that is flat with the surface makes the job look neat and well-done.

When you make a countersink, the top of a screw or bolt can sit flat or just a little bit under the surface. This is a very important thing to do for many kinds of jobs. Picture a piece of wood furniture. You do not want the tops of the screws sticking out. They could catch on your clothes or hurt you. With a countersink, the screw head is not in the way. The countersink makes a cone shape at the top of a hole. This lets a screw with a cone-shaped head fit just right. The angle of the countersink is often 82 degrees or 90 degrees. Which one you use depends on the kind of screw you have. The countersink bit you work with has to have the same angle as the fastener.

Making a countersink hole is a job with two steps. First, you drill a pilot hole for the main part of the screw. After that, you use a special countersink bit to make the opening that is shaped like a cone. It is important to be careful about how deep you make the countersink. If you drill too far down, the screw will be too low. If you do not drill deep enough, the screw will still stick out. What you want is for the top of the fastener to be perfectly flat with the surface of the material you are working on. Using a countersink is done a lot in jobs with wood and sheet metal. A countersink is an easy but very helpful thing to have in any shop with machines.

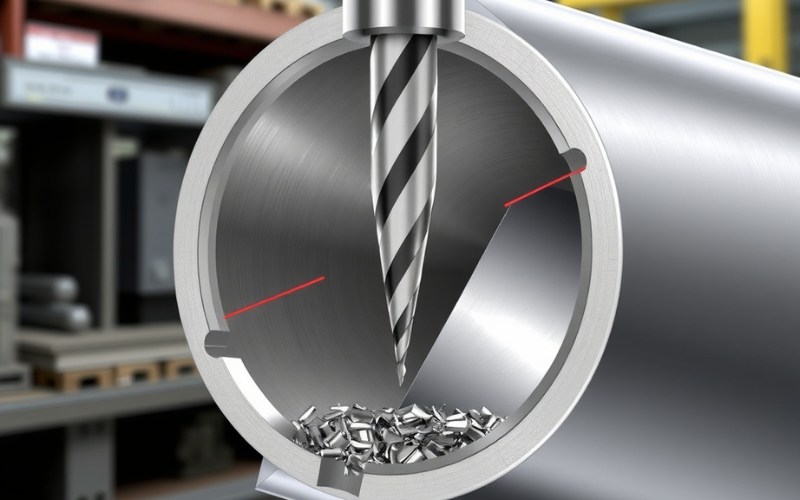

Now, we can talk about the counterbore hole. A counterbore is not the same as a countersink. I often make a counterbore when I need to hide the fastener so you can’t see it at all. A counterbore is a round hole with a flat bottom. It makes the top of another hole bigger. This bigger hole has walls that go straight down, at a 90-degree angle from the top. It is made to fit the top of a socket cap screw or a bolt that has a washer. The flat bottom of the counterbore gives a strong, flat place for the fastener to rest.

The reason for a counterbore is to let the head of the fastener go down into the material, below the surface. This is helpful when you need a surface that is flat and clear. For instance, think about a part of a machine where another piece has to move over that spot. The counterbore makes sure the fastener’s head won’t block anything. A counterbore is a round hole that has a flat bottom. It is a very common part of many designs for CNC machined parts. How deep you make the counterbore is important. It needs to be deep enough so the whole head of the fastener can fit inside.

To make a counterbore, you also have to drill a pilot hole first. After you drill the straight hole for the main part of the bolt or screw, you use a special tool for making a counterbore. This tool has a guide, or pilot, that helps it stay in the hole you already made. It also has sharp edges to cut and create the bigger, round hole. This makes sure the counterbore is exactly in the middle. The counterbore hole is a round, flat-bottomed hole that is lined up perfectly with the first hole. This means their center is in the same place. Using a counterbore is a very good way to make a connection that is strong and looks neat.

I have used a lot of my time to show new machine workers the differences between countersink and counterbore holes. It is a very basic idea to learn. The biggest difference is how they are shaped. A countersink has the shape of a cone. A counterbore is shaped like a cylinder and has a flat bottom. This is the largest and most easy-to-see difference. This difference in shape is because they are made for different kinds of fasteners. A countersink is for a fastener that has a head shaped like a cone, such as a flat-head screw. A counterbore is for a fastener that has a round head, such as a socket head cap screw.

Another main difference is the angle. A countersink has sloped sides. The most common angles are 82° and 90°. The angle of the countersink needs to be the same as the angle of the screw’s head. A counterbore, however, has sides that go straight up and down at 90° from the surface. It does not have a slope in the same way a countersink does. The sides of the hole run in the same direction as the hole itself. This makes a round space for the fastener head to sit in.

Here is a table to help you see the main differences:

| 기능 | 카운터 싱크 | 카운터보어 |

|---|---|---|

| 모양 | Shaped like a cone | Shaped like a cylinder with a flat bottom |

| Fastener Type | Flat-head screw (cone-shaped head) | Socket head cap screw, bolt with washer |

| 각도 | Sloped sides (like 82°, 90°) | 90° sides that go straight down |

| 목적 | To make the fastener head flat with the surface | To put the fastener head down below the surface |

It is very important to know these differences between a countersink and a counterbore for any job where you are making things. If you use the wrong one, it could make the connection weak, or the part might not fit right. These are common words used in CNC machining, and it is important to know what they mean.

I use a countersink bit very often. You should use a countersink any time you need a screw with a flat head to be flat with the top of the material. This is very common when working with wood. Think about building a cabinet or a bookshelf. You want it to look smooth and finished. You do not want to see the tops of screws sticking out. A countersink lets the head of a screw go down into the surface. This makes it look neat and well-done.

Another good time to use a countersink is when you are working with sheet metal. When you join two thin pieces of sheet metal, a countersink helps make the joint strong and smooth. It is also used in jobs for airplanes and spacecraft, where a smooth surface is important for how air moves over it. A countersink is also used to clean up the sharp edges of a hole. This means taking off the small, sharp bits of metal, called burrs, that are left after you drill. This makes the hole safer and cleaner. A tool for cleaning up edges is often just a simple countersink.

You should always use a countersink when the fastener you are using has a head that is shaped like a cone. The angle of the countersink must be the same as the angle of the fastener. This makes sure that the pressure from the screw spreads out in a good way. When the pressure is even, it creates a strong grip. Using a countersink is also important for materials that are softer, like wood or plastic. It stops the material from cracking when you make the screw tight. A countersink makes a nice spot for the fastener head to sit.

I decide to use a counterbore when I need a connection that is very strong for a bolt or a socket cap screw. A counterbore lets you use these strong fasteners so their heads don’t stick out and cause problems. A counterbore is made to hold the whole head of the fastener, and sometimes it can hold a washer too. This makes it sit lower than the surface of the material you are working on. This is important for machine parts where you need a flat surface so other parts can move over them.

A good time to use a counterbore is when you are building machines. If you are using bolts to join two metal plates, and you need the top to be totally flat, a counterbore is what you need. It allows the bolt to be put in and made tight without its head sticking up. This is also important for being safe. A bolt head that sticks out can be dangerous. The flat bottom of the counterbore gives a strong place for the head of the bolt or the washer to sit on. This gives it a very strong grip.

You should also use a counterbore when you are working with fasteners like socket-head screws. These fasteners have a tall head that is shaped like a cylinder. A countersink would not work for these kinds of fasteners. A counterbore hole is a round hole that is perfect for them. How deep the counterbore hole is becomes an important detail. It has to be deep enough to hold the entire head of the fastener. On plans for engineers, there is a special counterbore symbol to show where a counterbore needs to be drilled. It is used very often in jobs where you need a lot of strength.

Drilling a countersink and a counterbore is a job you have to do carefully. I have learned that if you go slow and are careful here, it helps a lot. For both of them, you always begin by drilling a pilot hole. This is the first hole for the main part of your screw or bolt. Be sure the hole has the right size for your fastener. A good, clean pilot hole is the first step to making a good countersink or counterbore.

To drill a countersink, once you have your pilot hole, you will use a countersink bit. This bit has a tip that is shaped like a cone. You put the bit into your drill and put the tip into the pilot hole. Then you drill slowly until the countersink is big enough for the screw head to sit flat. You should check to see if it fits with your screw while you work. You do not want to make the countersink too deep. After some practice, you will know how deep to go.

To drill a counterbore, you also begin with a pilot hole. Then, you use a counterbore bit. This bit has a guide on its end that fits into the pilot hole. This keeps the counterbore right in the center. The bit also has cutting parts that make the bigger hole with the flat bottom. You drill down until the counterbore is deep enough to hide the whole head of the fastener. You can use a machine called a drill press that has a depth stop. This helps make sure all your counterbores have the same depth. This helps you do a very neat job.

Using the right tools makes the job much easier. I always tell people that your work can only be as good as the tools you use. For a countersink, you will need a tool called a countersink bit. They are sold in different sizes and with different angles. The most common angles are 82° and 90°. It is a good idea to have a few different sizes of countersink bits. You will also need a drill, of course. A drill you hold in your hand can work, but a drill press lets you be more careful and exact.

For a counterbore, you will need a tool called a counterbore bit. These are a little more special for this job. A counterbore bit has a guide that helps it go into the pilot hole. They are sold in different counterbore sizes to fit different heads of fasteners. You will also need a drill. Once again, a drill press is better for this kind of work. That is because you can set the depth very carefully. A depth stop on a drill press is very useful for making counterbores that are all the same.

Here is a list of the simple tools you will need:

Having a good set of these tools will make the job of creating countersink and counterbore holes much simpler. Buying these tools is a good idea because they will help you do better work.

Every choice you make when working with machines has good things and bad things about it. I have learned to think about the good and bad parts of countersink and counterbore holes for every job. A very good thing about a countersink is that it is simple. It is easy to make with a simple countersink bit. It gives you a clean, flat surface, which is great for how it looks and for stopping things from catching on it. A countersink also helps lead the screw into the hole, which makes putting things together a bit easier.

But a countersink can also have some bad things about it. It does not give you a grip that is as strong as a counterbore. The sloped surface can also be a weak spot in some materials. It also does not work for every kind of fastener. You can only use it with screws that have a flat head. If you use it with another kind of screw, the connection will not be strong.

A counterbore has some very good things about it. It makes a very strong connection because of the flat place for the fastener head to sit. This makes it perfect for jobs with a lot of pressure. A counterbore can also hide the fastener head completely. This is great for how it works and for safety. It can be used with more kinds of fasteners, including strong socket cap screws and bolts.

The bad things about a counterbore are that it is a harder thing to make with a machine. You need to have a special counterbore bit. It also takes away more of the material you are working on, which might be a problem for some jobs. The sharp corners of a counterbore can also be a place where it might break under pressure. But for most jobs where strength is the most important thing, a counterbore is the better choice.

This is a question that people ask me a lot. And the answer is easy to see: a counterbore makes a stronger connection than a countersink. The reason for this is because of the way pressure is put on it. In a countersink, the pressure from the fastener is all focused on the sloped sides. This can be okay for jobs that do not need a lot of strength, but when there is a lot of weight or pressure, it can be a weak spot.

A counterbore, on the other hand, has a flat bottom. When you make a bolt or a socket cap screw tight in a counterbore, the pressure spreads out evenly over the flat area under the fastener’s head. This makes a connection that is much safer and stronger. The straight-up-and-down walls of the counterbore also help hold the fastener head. This is why you see counterbores being used in big machines and for building things.

So, if you are thinking about countersink vs counterbore and which is stronger, the counterbore is the one that wins. If your job needs to hold up against a lot of pressure, or if being safe is a very important thought, I would always tell you to use a counterbore. A countersink is great for making things look good and for fasteners in jobs that don’t need a lot of strength. But for strength and nothing else, the counterbore is the one to use.

I have seen people make a lot of mistakes when it comes to making countersink and counterbore holes. Here are a few common ones to be careful of:

By not making these common mistakes, you can be sure that your countersink and counterbore holes are made the right way every time. It just means being a little careful.