이스타르의 경험과 노하우를 바탕으로 여러분의 프로젝트를 시작할 수 있도록 도와드리겠습니다!

디자인 파일과 제작 요구 사항을 업로드하시면 30분 이내에 답변해 드리겠습니다!

Choosing between an FDM and an SLA 3D printing technology can seem hard. This is especially true when you are new to it. This article is here to share what I have learned with you. I am going to explain the big FDM vs. SLA choice in a very simple way. We will look at how each printer works. We will see what each one does best, and what they are not so good at. When you are finished reading, you will feel sure about choosing the right 3D printer for your needs. This will help you save money and make the best 3D print every time.

Let’s begin with the most popular kind of 3D printer, which is the FDM printer. FDM stands for Fused Deposition Modeling. That name sounds tricky, but how it works is easy. I like to think of an FDM printer as a very smart hot glue gun that a computer controls. It uses a long string of plastic, which is called a filament. It melts the filament and then builds your object, putting down one layer at a time. The printer nozzle goes back and forth on the x and y axes to make the shape for each layer.

It starts with a roll of thermoplastic filament. This is a type of plastic that gets soft when it is hot and gets hard when it cools down. The printer pulls this filament into a hot nozzle. The nozzle melts the plastic. Then, the printer starts to push out the melted plastic. It builds your 3D print from the bottom to the top. When one layer is done, the build platform goes down just a little bit. Then the printer starts to make the next layer. This is how FDM printing works. It builds layer by layer until your part is all done. It is one of the most popular 3D printing technologies because it’s so useful.

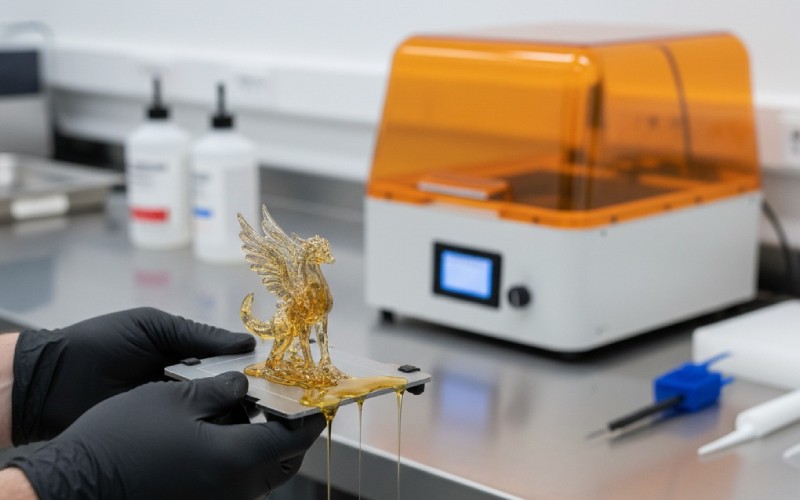

Now let’s talk about something very different. SLA 3D printing, or Stereolithography, does not use a filament. It uses a special liquid plastic called resin instead. This liquid resin turns hard when a special light shines on it. This light is usually an ultraviolet (UV) laser. An SLA printer works by using this light. It draws the shape of each layer on the top of a tank that is full of this liquid resin. This is a very exact way to make a 3D print.

Inside an SLA 3D printer, there is a tank of liquid resin. There is also a build platform that starts very close to the top of the liquid. A strong laser or a UV light from below shines up. It shines through the bottom of the tank. It draws the first layer of your 3D model. The liquid resin quickly turns into a solid plastic piece. The build platform then moves up a very small amount. The printer then draws the next layer. This keeps happening until your nice, very detailed 3D print is done. It hangs upside down from the build platform.

When you look at FDM and SLA together, the biggest difference is how they make things. FDM and SLA 3D printing both make objects layer by layer from a 3D CAD file. But the way they print is very different. An FDM printer has to move its nozzle all around to push out plastic. This can be a little slow and loud. You can easily see and hear it working. It is a machine with moving parts. This printer is busy making a real object, almost like a small robot.

SLA, on the other hand, is a much quieter and smoother process. It has fewer moving parts. Instead of a nozzle that moves, a light does all the work. The laser inside an SLA printer can move very fast and with great aim. Because it uses light to make the part, it can make things with much smaller details. The SLA printing process is about light and chemicals. The FDM process is about heat and moving parts. This main difference between FDM and SLA causes all the other good and bad points.

The materials you can use are a very big part of the FDM vs. SLA choice. An FDM printer uses rolls of solid thermoplastic filament. This is a good thing because there are many types of FDM materials to pick from. You can get normal plastics like PLA and ABS. These are great for making a simple prototype. You can also find strong, tough thermoplastic materials like PETG, TPU (which is bendy), and some that are even mixed with wood or metal. These FDM filaments are also not very expensive.

SLA printers use liquid photopolymer resins. These SLA materials have fewer choices compared to FDM, and they cost more. But, SLA resins are available with special features. You can find resins that are very strong, bendy like rubber, or even made for casting jewelry. You have many choices for 3D printing resins, but they need to be handled with more care. You must wear gloves when you touch liquid resin. The finished 3D print also needs to be washed and then cured with UV light to make it hard.

| 기능 | FDM (Fused Deposition Modeling) | SLA(광조형) |

|---|---|---|

| 재료 | Thermoplastic Filament (like PLA, ABS) | Liquid Photopolymer Resin |

| 작동 방식 | Melts and pushes out plastic | Uses UV light to harden liquid resin |

| 비용 | Cheaper printer and materials | More expensive printer and materials |

| 최상의 대상 | Working prototypes, big parts | High-detail models, smooth parts |

This is where the SLA 3D printer is the best. If you need to 3D print something with very small, complex details, you should pick SLA. An SLA printer uses a very exact laser to harden the resin. Because of this, it can make parts with super high resolution. The layer height is how thick each layer is. It can be as small as 25 microns. That is smaller than one of your hairs! This means the surface of an SLA print is very smooth. You can hardly see the layer lines. This smooth surface finish is very important for a lot of projects.

FDM printing, on the other hand, has a hard time with very small details. The size of the nozzle on the FDM printer sets a limit on how small a part can be. Even if you use a small nozzle, you will always see the layer lines on an FDM 3D print. You can sand and work on FDM parts to make them smooth. But FDM is not the best when you need a perfect surface right after printing. For a prototype where you must see every little detail, SLA is usually the better choice. This is because of its high resolution and ability to make parts that are very accurate.

When you talk about strength and how long things last, FDM is often the better choice. FDM parts are made from strong thermoplastic materials. These are the same kinds of plastics that are used in many things we use every day. The durability of FDM parts made from materials like PETG or ABS is very good. These parts have good mechanical properties. They can be dropped or have force put on them without breaking. This high strength makes FDM a great choice for making a working prototype that you need to test in the real world. The overall strength is one of its best points.

SLA parts are very nice to look at, but they can be easier to break compared to FDM parts. Normal SLA resin makes parts that are very hard, but they might break into pieces if you drop them. They can also get weaker if they are left in the sun for a long time because of the UV light. But, there are special tough and strong SLA resins that can make the mechanical strength better. But for the best strength and durability from the start, especially for a tough prototype, FDM 3d printing is usually the better pick. The thermoplastic materials used in FDM give it a big plus here.

Price is one of the main reasons people pick an FDM 3D printer. FDM machines are not very expensive. You can buy a good one to start with for only a few hundred dollars. The filament that an FDM printer uses is also very cheap. This low cost makes it easy for anyone to start 3D printing. The print speed of an FDM printer is quite good for making one prototype. But it can be slow if you need to make a lot of parts.

SLA 3D printing costs more. An SLA printer is more expensive, and the SLA resin costs more than filament. You also have to keep buying things like new resin tanks and cleaning items. When you think about print speed, it is a little tricky. For one small part, an SLA printer might be slower than an FDM printer. But an SLA printer can make lots of small parts at the same time just as fast as it makes one. This is because the laser only needs to draw each layer one time, no matter how many parts are on the build platform. This can make it faster for some kinds of jobs.

I use my FDM printer often for projects where how it works is more important than how it looks. FDM technology is wonderful for making quick prototypes. If I have an idea for a new tool or a part, I can make a 3D model. Then, I can have a real prototype in my hands in only a few hours. Because the materials are strong and cheap, I am not worried about testing the prototype. I can break it and then 3D print a new, better one.

FDM printing also has larger build volumes than most cheap SLA printers. If you need to make a really big 3D print, FDM is often the best choice. It is great for:

You should pick SLA when your 3D print must look perfect. The fine features and smooth surface finish that you get from an SLA printer are better than any other. I use my SLA 3D printer when I need to make parts that look amazing. For any prototype where the look is very important, SLA is the clear winner. The amount of detail is just wonderful.

This is why SLA uses are popular in areas like making jewelry, for dentists, and for making models for games and movies. SLA is great at making small, complex parts that are very accurate. If you are making a detailed prototype to show someone, an SLA print will make them happier than an FDM print. You should choose SLA if your project includes:

So, after looking at everything, which printer should you buy? The FDM vs. SLA 3D discussion is all about what you plan to make. There is no single “best” 3D printer. There is only the best printer for the job you want to do. Both FDM and SLA technologies are wonderful tools. They give you many ways to create things. The choice between FDM or SLA is based on what is most important to you.

If you are just starting, have a small budget, or need to make strong, working parts and prototypes, an FDM printer is the best choice for you. It is a printer that can be used for many things and is easy to learn with. It will let you learn about 3D printing without spending a lot of money. But, if your work needs the very best detail, the smallest features, and the smoothest surface, you will need to get an SLA printer. It costs more, but for the right kinds of projects, the results are worth the price. Think about the 3D print projects you want to do and pick the printer that is the best fit.