이스타르의 경험과 노하우를 바탕으로 여러분의 프로젝트를 시작할 수 있도록 도와드리겠습니다!

디자인 파일과 제작 요구 사항을 업로드하시면 30분 이내에 답변해 드리겠습니다!

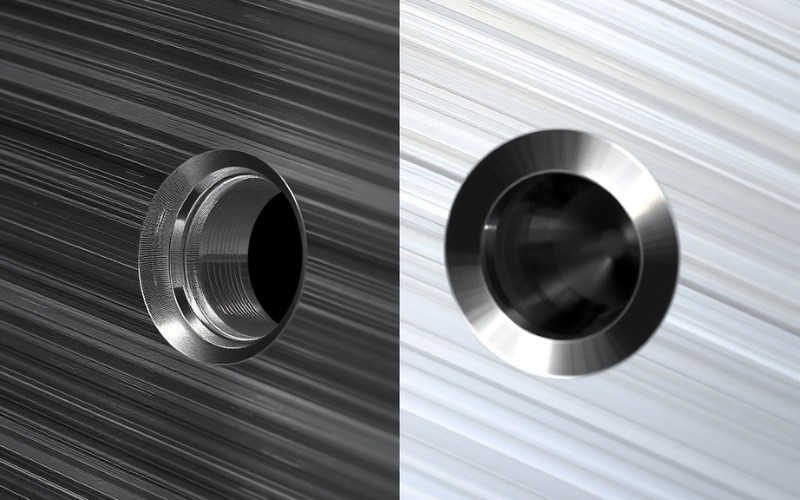

The difference between a spotface and a counterbore hole may seem small. But it can make a big difference in how a part works. This article will explain these types of holes in a simple way. We will look at what makes them different. We will also see when to use each one, and how they are shown on plans. When you finish reading, you will understand these important parts of a machine.

Have you ever looked at furniture and seen that the screws sit down low so they do not stick out? That is often because of a counterbore hole. I see a counterbore as a hole with two levels. First, there is a smaller hole that goes into the material. This is called a pilot hole. Then, a bigger, flat-bottomed cylindrical hole is cut at the top. This makes a step inside the hole. The main job of a counterbore is to let the head of a screw or bolt sit flush with the surface of the part. Or, it can sit below the surface. This is important for a few reasons. It can make the part look nicer. It can stop the screw or bolt from bumping into other parts. And it gives a flat surface for the fastener to press on.

A counterbore is a round, sunken area that is cut into the top of a hole. The important thing to know is that it’s a cylindrical hole with a flat bottom. This shape is just right for fasteners with round heads, like socket head cap screws. When you are putting parts together, a fastener that sticks out can be a big problem. It can catch on things. Or it can stop other parts from fitting the right way. A counterbore hole fixes this. It makes a small pocket for the fastener to hide in. The machine that makes these holes must be very exact. It needs to get the diameter and depth just right. Any good CNC machining service can make these types of holes easily.

Now we can talk about the spotface hole. I like to think of a spotface as a very shallow counterbore. It is still a flat-bottomed, round sunken area around a pilot hole. But it is not as deep. The main job of a spotface is to make a flat and smooth spot for a fastener to sit on. Think about a part that has a rough or bumpy surface. If you try to tighten a nut or bolt on that surface, it may not sit flat. This can cause issues with how well the screw or bolt holds. It can even hurt the part. A spotface hole is a special spot made by a machine. It makes that area around the hole smooth. This gives the fastener a good spot to sit.

A spotface is different from a counterbore. It is usually not made to hide the fastener head all the way below the surface. It is only deep enough to make that very important flat surface. You will often see spotface holes on cast or forged parts. The surface of these parts can be a little bumpy. By using a machine to make a small, flat area, we make sure that the screw or bolt touches well. This also helps spread the pressure out in a balanced way. This is a simple but useful way of using a machine to make the connection better. A machine will make this spotface feature with a special spotface tool. This is to make sure the surface is clean and flat.

For me, the easiest way to recall the biggest difference between a counterbore and a spotface is to think about how deep they are. A counterbore is a deeper hole. It is made to sink the head of a fastener below the surface of the material. A spotface, on the other hand, is a very shallow counterbore hole. It is just deep enough to make a flat surface for the fastener to sit on. So, the biggest difference is the depth of the top part of the hole.

Here is a simple table to show the differences between spotface and counterbore holes:

| 기능 | Counterbore Hole | Spotface Hole |

|---|---|---|

| 주요 업무 | To sink a fastener head below the surface. | To make a flat seating spot for a fastener. |

| 깊이 | Deep enough to hide the fastener head. | Very shallow, just enough to make a flat surface. |

| 공통 사용 | When a flat surface is needed for looks or for parts to fit. | On rough or bumpy surfaces to make a good connection. |

| Final Look | The fastener head is hidden. | The fastener head sits on a flat, machine-made surface. |

So, when you look at a machine-made part and you want to know if you are seeing a counterbore or a spotface, ask yourself this question: Is the fastener head hidden, or is it sitting on a small, flat circle? The answer will usually tell you what it is.

The choice to use a spotface vs a counterbore depends on what you need the fastener to do. If you have a case where a screw or bolt head sticking out would be a problem, then a counterbore is the best choice. This could be because it would get in the way of another part. Or, it could be because you want a clean, smooth look. The main job of a counterbore is to get that fastener head out of the way.

On the other hand, you should use a spotface when the surface of your part is not completely flat. Castings and forgings are good examples of when you would use a spotface. These parts often have a rougher surface. A spotface makes a small, flat spot. This helps make sure the fastener sits correctly and tightly. It is all about making a connection that is strong and will not fail. So, if the surface is bumpy, and you need a good seat for your fastener, a spotface is the right choice. It is a simple hole with a big job.

Yes, from what I have seen, the way of doing it is alike, but there are special tools for making counterbore and spotface holes. For a counterbore, a person running a machine will often use a counterbore tool. This tool has a pilot on the end. The pilot fits into the pilot hole that was drilled first to keep it in the middle. Then, sharp parts that cut make the wider, flat-bottomed hole. You can think of it as a drill bit with a smaller guide on its front.

For a spotface, a spotface tool or a spotface cutter can be used. These tools are made to make that shallow, flat surface. An end mill can also be used to make both counterbore features and spotface features. The tool you choose is based on the specific machine you are using and the material you are cutting. Both CNC machining and manual milling can be used to make these types of holes. The most important thing for the person running the machine is to use the right tool. This will help them get the right diameter and depth for the job.

On plans for engineering, special symbols are used to show exactly what needs to be done. The symbols for spotface and counterbore holes are alike, which can be hard to understand at times. But there is an important difference. The counterbore symbol is ‘⌴’. You will see this symbol on a drawing. It will be followed by the diameter and depth of the counterbore. This tells the person running the machine all they need to know to make the correct counterbore hole.

The spotface symbol is a lot like the counterbore symbol. To show that it is a spotface, the letters “SF” are put inside the counterbore symbol. So, when you see the counterbore symbol with “SF” inside, you know it is asking for a spotface. The drawing will also tell you the diameter of the spotface. At times, the depth of the spotface is not given. In that case, the person running the machine just needs to make the surface clean and flat. These symbols are a very important part of the language of machining and woodworking. They help to make sure everyone understands the same thing.

We have talked a lot about the spotface vs counterbore topic. But it is good to also talk about other types of holes you will see in machining. I have found it useful to know a little bit about these too. A simple hole is just what it sounds like. It is a basic drilled hole with nothing special about it. Then there is a through hole. This kind of hole goes all the way through the part. A blind hole is a hole that only goes part of the way through.

Another hole you will see a lot is the countersink hole. A countersink makes an opening shaped like a cone at the top of a hole. This is just right for flat-head screws so they can sit flush. You will see these often in woodworking and metalworking. A tapered hole is a hole that gets wider or narrower as it gets deeper. These are only a few examples of the different types of holes in machining. Each one has a special job. This is just like our spotface and counterbore holes.

From what I have seen, the way to make counterbore and spotface holes is quite simple. It always begins with a pilot hole. This is the smaller, deeper hole that the long part of the screw or bolt will pass through. This pilot hole will be shown on the plan. After the pilot hole is drilled, the person running the machine will then make the wider part of the hole. For a counterbore, a counterbore tool is used to cut the deeper, flat-bottomed hole. For a spotface, a spotface tool is used to make the shallow, flat surface.

The most important part of this work is making sure the two holes are lined up perfectly. This is called being coaxial. If the holes are not lined up, the fastener will not fit right. This is where modern CNC machining is really great. A CNC machine can do these jobs very, very accurately. This makes sure the result is perfect every time. Using the correct machining processes is needed to make very good machine-made parts.

I have learned that in machining, the small things are important. The surface finish of a spotface or counterbore might seem like a small detail. But it can be very important. For a spotface, a smooth surface finish is very important. This is because its main job is to make a flat, smooth spot for the fastener. A rough surface could make the fastener not tighten down correctly. The spotface provides a flat surface around a hole. This is to make sure the connection is strong.

For a counterbore, the surface finish on the sides of the hole is usually not as important. But, the flat bottom of the counterbore where the fastener head sits should be smooth. This is to make sure the pressure is spread out evenly. A good surface finish does not just help the part work well. It can also make it look better. A good machine shop will be very careful about the surface finish. This is to make sure the part that is finished is made exactly right.

To really know the difference between a spotface and a counterbore, it helps to think about where you might find them in the real world. I have seen counterbore holes used in many different uses. For example, in making cars, you will find them used to sink bolts in parts of an engine. This is to stop them from bumping into other parts. In electronics, they are used to make sure screw heads do not stick out and get caught on wires. Basically, any time you have a screw or bolt that needs to be hidden, a counterbore is a good choice.

Spotface holes are also seen a lot, especially in jobs where things need to be very strong. You will often find them on cast iron parts. These can be the bottoms or covers of machines. The process of casting can leave a rough surface. So a spotface is cut by a machine to make a clean, flat spot for a bolt to tighten on. This makes sure the connection is strong and won’t break. The next time you are looking at a machine, try to see the difference between a spotface and a counterbore. It is a fun way to see these ways of cutting metal being used.

To finish up, here are the most important things to remember about spotface and counterbore holes: