이스타르의 경험과 노하우를 바탕으로 여러분의 프로젝트를 시작할 수 있도록 도와드리겠습니다!

디자인 파일과 제작 요구 사항을 업로드하시면 30분 이내에 답변해 드리겠습니다!

People get confused when they have to pick materials. Two materials that look alike can be the reason a medical device works or fails. Two materials that often cause this confusion are Thermoplastic Elastomers (TPE) and medical silicone. They can look and feel alike, but what they are made of makes them good for different things. This article is worth reading because I’m going to explain the main differences between TPE and silicone, using what I’ve learned from doing the work myself. We’ll look at how they are shaped and how safe they are for the body, helping you figure out what your product needs so you can make a good choice. Getting this choice right stops problems and saves money later on.

When I first started working with polymers, the world of soft, stretchy materials seemed very confusing. But one material that always stood out for how useful it is for so many things is the Thermoplastic Elastomer, or TPE. What is it? You can think of it as a material that gives you the good parts of two different things: the stretchy, soft feel of rubber and the easy shaping of plastic. This special mix makes TPE a popular and widely used material in many fields, and it is used a lot for medical items. This useful material is durable and comes in many forms that engineers can choose from when designing parts.

The magic of TPE is in how it’s built on a tiny level. It’s a type of polymer that can be melted and made into new shapes again and again without getting ruined, which is what a thermoplastic does. This is a big help when making things, as it makes the molding process simpler and can make it much cheaper to produce things. Other kinds of rubber go through a forever change when heated (a process called a cure), but TPE just gets soft and can be shaped again. This ease of processing makes TPE a great pick for many different components, especially when making a lot of them at once. TPE is a robust material for many things.

The fact that you can process it again also means TPE is great for jobs where you need to do overmolding, which is when it’s stuck to a hard piece of plastic, like the handle on a doctor’s tool. It can even be made to stick with plastics like polyamide. This power to be melted and molded again is why it’s so valued. We see this material used for many things, from simple handles to harder parts of a medical device. It’s truly a hard-working elastomer. A similar material you may hear about is thermoplastic polyurethane (TPU). TPU is a certain kind of TPE that is very strong; sometimes people say thermoplastic polyurethane when they are talking about all TPEs.

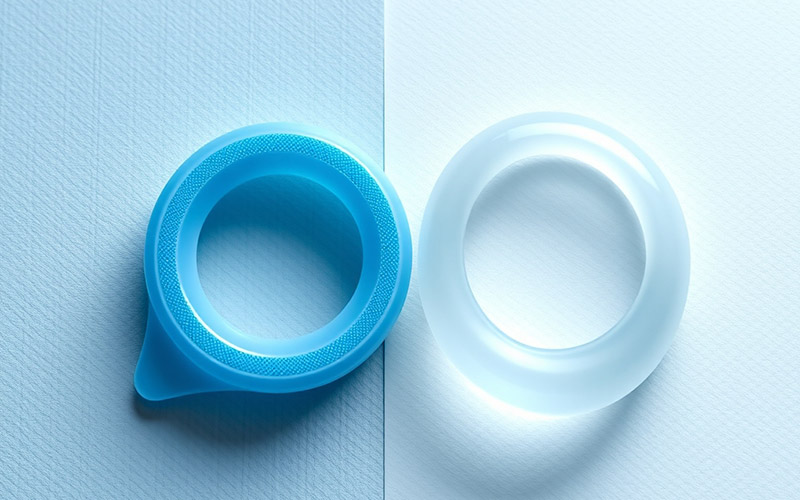

Now, let’s talk about silicone. I remember a customer who kept calling a TPE part “silicone,” and it made things very confusing. It’s a common mistake; a soft TPE can feel a lot like silicone rubber. But they are very different in a basic way. Medical silicone is a thermoset, not a thermoplastic. This means once it’s shaped and cured, it stays that way forever. You can’t melt it down and use it again. This cure process makes strong connections inside the material that don’t change, giving medical-grade silicone some really great features.

There are different types of silicone, like high-consistency rubber (HCR), which is also called HTV (high-temperature vulcanizing), and liquid silicone rubber (LSR). For medical jobs that need to be exact, LSR is often the preferred choice. The main difference from TPE is that it’s very stable. Medical silicone stays flexible, strong, and safe over a wide range of hot and cold. A TPE might get soft or break when it gets very hot or cold, but high-quality medical silicone will stay strong. This makes it a very important material for medical applications because you can count on it.

This stability is why health care companies have used it for many years. When you need a material that is very safe for the body and can handle being cleaned many times with strong methods, medical silicone is usually the right answer. The name “medical-grade silicone” means something; it means the material has passed hard tests to make sure it’s safe to touch people and can be used in a medical device. This is a very important difference that makers of medical devices need to know. TPE is a great material, but silicone rubber is a top choice for a reason.

I’ve spent a lot of time in places where things are molded, and the way LSR is molded is really interesting. LSR molding is a special kind of injection molding. Unlike plastic bits that are melted in a tube, LSR starts as two separate liquids. These two parts are pushed through a mixer, which blends them, and then into cool tubes. A key thing here is a platinum-based helper that starts the cure. The material flows easily into a hot mold space.

Once inside the hot mold, something cool happens. The heat makes the curing happen faster, and the liquid silicone rubber turns solid into its final shape in just a few seconds. Because LSR is a runny material, it can fill up parts of a mold that are very tricky and have small details. This makes it ideal for making fragile parts that are long and thin or have fancy shapes. This process is perfect for making high-quality silicone components that are very exact. The silicone injection molding process is very good for the right type of part.

One of the hard parts of LSR molding is handling flash. Since the material flows so easily, it can leak into very small cracks, like where the mold closes. This makes thin pieces of extra material you don’t want, called flash. This needs very exact tools and careful control of the process. We also have to be careful with injection-molded LSR parts that are very thin; we must plan the process to stop them from bending or losing their shape as they cool. When an LSR molding process is done right, you get a perfectly shaped, strong part that doesn’t need much cleanup work.

So, when is it a good idea to pick TPE? I’ve helped many customers choose TPE when what they need matches what TPE is good at. The main reason is often that it costs less and is easier to make, especially for products you make a lot of. Because TPE can be made with regular plastic molding machines, the cost for tools and for making the parts is usually lower than for LSR molding. This ease of processing makes it a great choice.

TPE is great for uses where a “soft-touch” feel is important to make it easy to hold or comfortable for a patient, but where you don’t really need the ability to handle very hot temperatures or the body-safety of medical silicone. Think about handles on tools you hold, soft buttons, or soft guards on medical equipment. A medical grade TPE is pretty safe from chemicals and can be cleaned in certain ways, which makes it good for many parts of a medical device that aren’t the most important. When we need to stick a soft material to a hard plastic, TPE is often the best choice.

Here’s a quick list for when TPE might be the right material for your medical application:

If you said “yes” to most of these, then a high-quality TPE is probably a good choice. You really have to understand product requirements to make the best decision.

On the other hand, there are many times when you must use LSR. When I work with a team making a medical device that will touch someone’s body for a long time or be used inside the body, I almost always suggest using medical silicone, and usually medical LSR. The reason is one very important thing: biocompatibility. Commercial LSR, especially medical-grade LSR, is very clean and does not react with things. It doesn’t leak chemicals, help germs grow, or cause bad reactions in the body. You must have this for things like breathing tubes, catheters, and parts put inside the body.

On top of its safety, how tough LSR is makes it the preferred choice for hard jobs. This robust material can handle hot temperatures without breaking down, which is needed for cleaning methods like using hot steam (autoclaving). It also doesn’t get squashed flat. This means if you squeeze it for a long time (like in a seal or a valve), it will bounce back to its first shape after you stop. A TPE might get stuck in the new shape in the same spot. This is why LSR is the top material for seals and gaskets that have to work very well, and for fragile parts inside a medical device.

The FDA has strict rules for materials used in the medical sector, and LSR has a long history of passing these tough rules. When the part cannot fail and you need to be sure it will work, health care companies choose medical LSR. The fact that it is clean, stable, and strong makes it ideal for applications that need the best safety and strength. It is an excellent elastomer for many important needs.

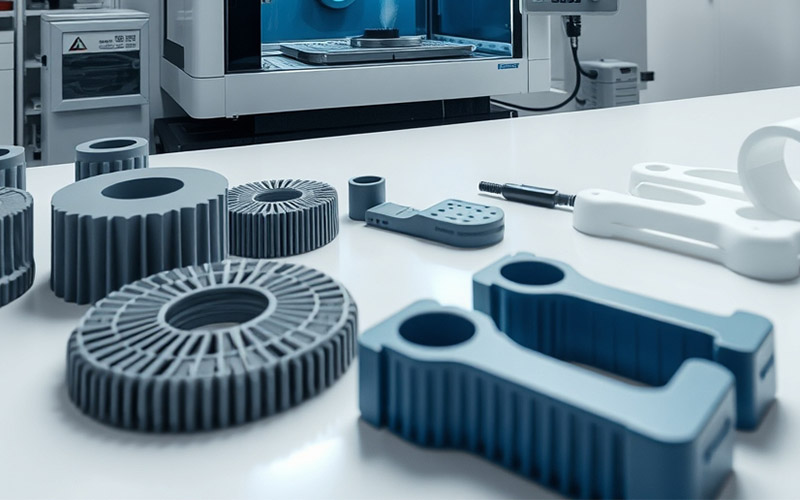

Yes, for sure. Both TPE and silicone are used a lot in molding to make many different kinds of parts. But, it is very important to know that the 종류 of molding is different. You can’t just switch them. I’ve seen teams make expensive mistakes by thinking they could use the same tools or methods for both. TPE and silicone each have special needs that come from how they are made up chemically—one is a thermoplastic and the other is a thermoset.

The confusion between “TPE and silicone” often happens because the finished parts can look alike. Both can make soft, stretchy parts. Both can be used to make a seal. Both are important materials to choose from when making things for the medical field. But the way you get from the starting material to the final part is totally different. A TPE part comes from a thermoplastic molding process, and a silicone part comes from a thermoset molding process like liquid silicone rubber molding.

To say it simply, you can’t just put LSR into a machine made for TPE pellets and hope it works. How you heat and cool it, the pressure, the shape of the tools—it’s all different. So while you can mold both, you can’t swap them in the same process. You have to pick the right material first, and that choice tells you which way you need to make it. Knowing these making differences is just as important as knowing what the materials are like.

Let’s look more closely at the molding process for a thermoplastic material like TPE. I like to think of it as a cycle of melting, shaping, and cooling. We start with small, hard bits of TPE, which are put into the tube of an injection molding machine. A big screw inside the tube heats and melts the bits into a thick liquid. This hot liquid is then pushed with high force into a cool mold.

Once the material fills up the mold, it starts to cool down and get hard, taking the shape of the mold. The cooling part is very important; it’s what lets you make parts faster, which is a big help when making lots of things. After a short time to cool, the mold opens, and the hard, finished part is pushed out. The great thing about a thermoplastic elastomer is that any leftover bits or bad parts can be chopped up and used again, which lowers waste and cost. This is a main benefit of thermoplastic molding.

In contrast, molding a thermoset like silicone is the opposite process. With silicone, you push a cool material into a hot mold to make it cure. With a thermoplastic like TPE, you push a hot material into a cool mold to make it solid. This basic difference changes everything from how the machine is set up to how long it takes to make a part. The molding process for TPE is usually faster and uses less power, which helps make it cheaper to produce.

When we talk about any material for medical use, the first thing I always ask about is its biocompatibility. This is a way to tell how well a material gets along with the human body. Will it make someone have a bad reaction? Will it be bad for them? For any medical device, especially ones used inside the body, great biocompatibility is very important. This is one place where there is a clear difference between normal TPE and medical-grade silicone.

Medical-grade silicone, especially LSR, is the best choice for biocompatibility. It has passed many biocompatibility tests to meet rules like USP Class VI and ISO 10993. How it is made up is very stable, which means it won’t fall apart or leak stuff when it touches body fluids. This is why it is trusted for parts that stay in the body a long time, catheters, prosthetic devices, and other uses that need to touch people for a long time. The platinum-based helper used in medical LSR makes a very clean final polymer.

There are special kinds of TPE, like medical grade TPE, that have good biocompatibility for some uses, but they usually aren’t as non-reactive as medical silicone. TPE materials are made of more things and can have softeners in them that could leak out after a while, especially after being cleaned many times. For uses where it touches the skin or is used for a short time, a high-quality TPE is often very safe and fine. But for very important uses, the long history of medical silicone working well makes it the safer, better choice. You have to understand product requirements to know what level of biocompatibility is needed.

I have talked about this, but this needs its own section because people often get it wrong. Yes, the way you make parts from silicone and thermoplastic materials is completely different. It is all because of that one basic difference: thermoplastic vs. thermoset. To really get why you can’t switch them, you need to know how they act when you heat them. A thermoplastic, like TPE or its relative TPU, gets soft like a liquid when heated and gets hard when cooled. You can do this over and over.

Silicone is a thermoset, so it acts the other way. It starts as a liquid or a soft solid and gets hard for good when it cures with heat. You cannot change it back. This difference decides how you have to set up all your machines.

Here is a table to make the difference clear:

| 기능 | Thermoplastic (TPE) Process | Silicone (LSR) Process |

|---|---|---|

| Starting Material | Solid pellets | Two-part liquid |

| 프로세스 | Melted, pushed hot into a cool mold | Mixed, pushed cool into a hot mold |

| 주기 시간 | Usually faster | Usually slower |

| 툴링 | Regular injection molding tools | Special, very exact tools |

| Scrap/Waste | 재활용 가능 | Cannot be recycled (thermoset) |

| Energy Usage | Lower, because it’s faster | Higher, because the mold is heated |

As you can see, from the material to the machines and power needed, the ways of making them are basically different. Knowing the difference between how silicone and thermoplastic parts are made is the first step to not making costly mistakes in your design and building. You must understand product requirements to pick the right way.

This is the most important question. In all my work, the projects that worked out well were the ones where the team was careful to really understand what the product needed before they started designing it. Picking between TPE vs. medical silicone is not just a random talk; it’s a choice you must make based on what your medical device needs to do. If you hurry this step, you will have problems later.

First, figure out where the part will be used. Will it get very hot? Will it need to be cleaned in a special way? If yes, what way (hot steam, gamma, EtO)? Medical silicone is fine with all common cleaning methods, but TPEs are not. Second, think about the physical job it has to do. Does the part need to stretch and bounce back to its original shape, like a valve or seal? Or does it just need to be a soft, easy-to-hold handle? LSR will be great for jobs that need a lot of physical strength.

Last, and most important, how will it touch a patient? Is it a handle that is touched for a few minutes? Or is it a catheter that will be inside a patient for days? For more than just touching the skin, the much better biocompatibility of medical-grade silicone is almost always what you must choose. You have to be honest and careful here. Sit down with your team and make a list. Be specific. Only when you have a very clear idea of your product’s job can you pick the right material without worry. If you don’t understand product requirements, you are just guessing.

To finish, let’s go over the most important things to remember from our talk on TPE and medical silicone.