Deixe a Istar ajudá-lo a iniciar o seu projeto com a nossa experiência e know-how!

Carregue os seus ficheiros de desenho e requisitos de produção e entraremos em contacto consigo no prazo de 30 minutos!

Homopolymer and copolymer might sound hard to understand. But the idea behind them is easy. If you know how homopolymers and copolymers are different, you can save time. You can also save money. This article will explain everything in a simple way. I will help you understand what they are. I will show you how they are not the same. And I will help you choose the best material for your job.

Let’s begin with the simple parts. What is a polymer? Picture a very long chain. Now, picture the single links that make the chain. When we talk about plastics, those single links are very small molecules. We give these small molecules a name. They are called monomers.

When you join many monomers, you make a polymer. The word “poly” means many. So, a polymer is just a long chain of many monomers. Nearly every plastic you see is a kind of polymer. The way this chain is built is very important. How the monomers connect makes the final polymer material. These long polymer chains are what make plastics strong. They also make them able to bend. This is an easy idea. But it is the most important thing to know to understand homopolymers and copolymers. A polymer made like this can have a lot of strength.

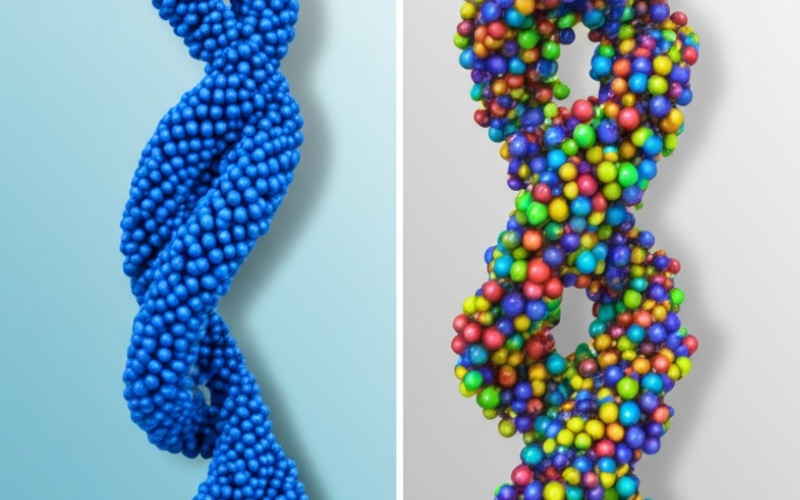

Now, let’s talk about a homopolymer. The name itself gives you a clue. “Homo” means “the same.” A homopolymer is a polymer. It is made from just one type of monomer. Every single link in the chain is the same. Picture a necklace that has only red beads. That necklace is like a homopolymer.

A homopolymer is made of one repeating unit, over and over. Because of this, it often has a very neat and orderly structure. This neat structure can make homopolymers very strong. It also makes them hard to bend. They are also often very good at resisting being pulled apart. This is called high tensile strength. This is why a homopolymer is a great pick for some jobs. Some common homopolymers are ones you have probably heard of. We will see some examples in a little bit. The main thing to remember is this. Homopolymers are made from just a single type of monomer.

A homopolymer uses one kind of monomer. So, what do you think a copolymer is? You are right! “Co” means “together.” A copolymer is a polymer. It is made from two or more different types of monomers. It needs to have at least two different kinds. Think about that necklace one more time. A copolymer necklace would have red beads and blue beads mixed in. A copolymer is made up of multiple kinds of monomers.

This mix of different monomers gives a copolymer special abilities. A manufacturer can change the kinds of monomers used. They can also change how they are put together. This lets them make a copolymer with the exact qualities they want. Whereas copolymers can be made soft, bendy, or strong, a homopolymer usually has fewer options. A copolymer gives people more freedom to design things. Having a second monomer changes the chemical structure of the polymer. This is what makes a copolymer so helpful. The copolymer can be designed to do a special job. This makes the copolymer useful for many different things.

I think a simple table helps to show the difference quickly. The big difference in the homopolymer vs copolymer question is about what they are made of. Let’s look at the main differences between homopolymers and copolymers.

| Caraterística | Homopolímero | Copolímero |

|---|---|---|

| Kind of Monomer | Just one type of monomer. | Two or more types of monomers. |

| How It’s Built | Easy, neat repeating unit. | More complicated, mixed repeating unit. |

| What It’s Like | Usually harder, stronger, with higher crystallinity. | More bendy, better at taking a hit. |

| Exemplo | Polypropylene, polystyrene, PVC. | ABS plastic, nylon, styrene butadiene rubber. |

The main difference is the type of monomer. Homopolymers use just one. A copolymer uses two or more. This single change in the chemical recipe makes everything different. The way it is built changes how the polymer works. For instance, the high crystallinity in many homopolymers means they are not as see-through as a copolymer. A copolymer can often handle being pulled or bent better. The homopolymers vs choice all depends on what you need it to do.

Both homopolymers and copolymers are made using a process. This process is called polymerization. This is the chemical process that joins monomers together to make a long polymer chain. I want to tell you about two main ways this is done. One is called addition polymerization. The other is called condensation polymerization.

In addition polymerization, monomers are added one after the other. You can think of it like clicking Lego bricks into place. A homopolymer like polyethylene is formed through addition polymerization. You can also make a copolymer using this method. The process makes a long chain of atoms. These are usually carbon atoms.

In condensation polymerization, two monomers come together. When they join, a small molecule, like water, is let go. This is the way materials like nylon and polyester are made. Nylon is a well-known copolymer. The kind of polymerization used helps to decide the final shape and features of both the homopolymer and the copolymer. The main point of polymerization is to make a strong bond. This bond connects each molecule.

Yes! This is where it gets very interesting. A copolymer has different monomers. Because of this, you can put them together in different patterns. This makes different kinds of a copolymer. The pattern of the monomers along the chain changes how the copolymer acts. A copolymer can be made to be very bendy.

Here are the four main kinds of a copolymer:

This is the main question: homopolymer or copolymer? The answer is: it depends on the job you need it to do. Homopolymers are usually harder and have higher tensile strength. They are good when you need something that doesn’t bend. Their simple build gives them good stability.

But, copolymers have better strength for taking hits. They are also more bendy. When you add a second monomer, you can mess up the neat chain structure. This makes the material stronger and less likely to break. A copolymer can usually handle being pulled or hit better than a homopolymer. This is the reason a copolymer is used for things that must bend or take a hit. We can talk about certain mechanical properties. A copolymer is often better at holding its shape under a load for a long time. This is called creep resistance. The mechanical properties of a copolymer can be changed. For instance, glass-filled copolymers are very strong. The mechanical properties of a homopolymer are usually set and harder to change.

Yes, of course. You see homopolymers all the time. They are some of the most widely used plastics in the industry. Their simple build makes them easy to manufacture.

These homopolymers do a lot of the heavy lifting in the manufacturing industry. They are simple and they work well. And we are good at making them.

Copolymers are everywhere, too. They are often used for jobs that homopolymers could not do. Their special mechanical properties make them just right for hard jobs. A copolymer is a material that solves problems. Copolymers include materials that are strong and can bend at the same time.

Copolymers are made from two or more monomers. This lets them have many different features. Copolymers consist of two or more building blocks. A copolymer can even be used as a thin barrier, called a membrane. It can also be used in self-polishing paint.

So, with all this information, how do you pick between a homopolymer and a copolymer? I always think about what the part needs to do first. Ask yourself some questions. Do I need something hard that can resist being pulled? A homopolymer could be the best choice. Do I need something that can bend and take a hit? A copolymer is probably a better pick. The homopolymer vs decision depends completely on the job it has to do.

Think about how the part will be made. Ways of making parts like injection molding, blow molding, thermoforming, or sheet extrusion can be used for both homopolymers and copolymers. But a certain kind of copolymer might be easier to work with. You should speak with your material manufacturer. They can help you choose the best material, whether it is a homopolymer or a copolymer. Think about how the plastic parts will touch the world around them. Will they be around any chemical substances? Some copolymers are better at resisting damage from chemicals. Picking between a homopolymer and a copolymer is a big decision. Whereas copolymers give you more options for bending, a homopolymer gives you more stiffness. I hope this guide makes that decision easier for you.