Tecrübemiz ve bilgi birikimimizle Istar'ın projenize başlamanıza yardımcı olmasına izin verin!

Tasarım dosyalarınızı ve üretim gereksinimlerinizi yükleyin ve 30 dakika içinde size geri dönelim!

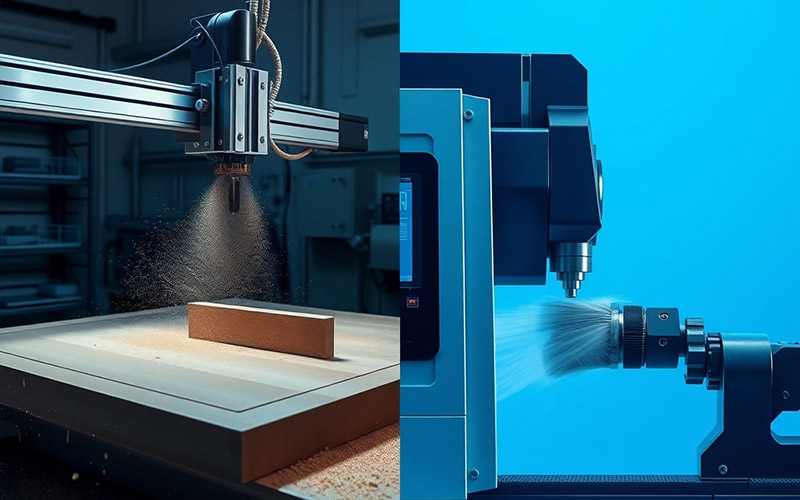

Hello, I’m Robert. I have worked with machines for many years. In that time, I’ve seen many people get mixed up. They don’t know if they should choose a CNC router or a CNC mill. The machines look alike, and they both cut things. But they are very different tools that do very different jobs. If you pick the wrong one, it can be a mistake that costs a lot of money.

I wrote this article to help you learn the big differences. I will explain everything with simple words. We will look at what each machine is best at. When you finish reading, you will know for sure which machine is the right one for your shop or your business. You will feel sure about your choice.

Before we talk about the differences between CNC routers vs CNC mills, let’s talk about what makes them alike. Both are kinds of CNC machinery. CNC means Computer Numerical Control. This means a computer gives the machine exact directions on how to move and cut. You make a design on a computer with CAD and CAM software. Then, the CNC machine makes your design real.

Both a CNC mill and a CNC router use a method called subtractive manufacturing. This is just a simple idea. It means they cut material away from a bigger piece. We call this piece a workpiece. Picture a person carving a statue from a big piece of stone. That is a subtractive method. These machines do the same thing. But they use a spinning cutting tool and are very, very exact. The main difference between a CNC mill and a CNC router is in the small details of how they do this work.

These commonly used CNC machines are great tools. They can make anything from a simple sign to a difficult part for an airplane. Learning the key differences between CNC routers and mills is the first step. It helps you pick the right machine tool for what you need. We will look at the different things about these CNC machines to help you make the right choice.

A CNC router is a machine that is made to cut softer things. Think about materials like wood, plastics, foam, and some softer metals like aluminum. The CNC router has a big space to work on, which is usually a flat table. The workpiece is held down on this table. The machine moves a cutting tool over the top of the material to make cuts.

CNC routers work by moving the cutting tool in three directions. These are called the X, Y, and Z axes. The X-axis goes left and right. The Y-axis goes front and back. The Z-axis goes up and down. This lets the CNC router carve and cut in 3D. The spindle on a CNC router spins very, very fast. This high speed is great for making a smooth edge on materials like wood.

I have used a CNC router for a lot of projects. I have made everything from special cabinets to detailed signs. A CNC router is a machine that can do many jobs. A CNC router is usually lighter than a CNC mill. Because of this, it can move very quickly. This speed is a really good thing when you need to make many parts in a short time. A good quality CNC router can be a great tool for any workshop.

Now, let’s talk about the CNC mill. A CNC mill is a machine that is much heavier and stiffer. This is one of the most important differences. CNC mills are built to cut things that are hard. They can cut strong metals like steel and even titanium. The machine has a strong and stiff frame. This frame stops it from shaking or moving while cutting these hard metals.

A CNC router moves the tool over a workpiece that stays still. Some CNC mills work this way, too. But many are different. On many CNC frezeleme machines, the cutting tool does not move. Instead, the table that holds the workpiece moves under it. This design gives the machine more power for cutting. It can push the cutting tool deep into hard metal with no problems.

A CNC mill is the best at being exact. The machine is very strong and steady. Because of this, it can make very exact cuts. Mills are made for making difficult parts for engines, medical tools, and things for space travel. A CNC router is fast. But a CNC mill is strong and perfect in its cuts. It is a different kind of machine for a different kind of work.

This is the biggest and most important way they are different. If you only remember one thing from this article, remember this. A CNC router is made to cut softer materials. A CNC mill is made to cut hard materials. If you use the wrong machine for your material, it is a sure way to have a big problem.

I once saw a person try to cut a block of steel on a small CNC router. The machine shook a lot. The tool broke, and the project was ruined. It was a good lesson to learn. CNC routers are perfect for materials like wood, MDF, acrylic, plastic, and foam. They can also work with soft metals like aluminum, but you have to go slow. A CNC router works best when you need to cut softer materials and do it fast.

But CNC mills are built to cut hard things. They are very strong and stiff. This means they can easily cut through steel, stainless steel, and other hard metals like titanium. You use a CNC mill when the material you are cutting is very strong. Mills are usually the right machine when you need to make a metal prototype or a final part made of metal.

| Özellik | CNC Router | CNC Freze |

|---|---|---|

| Main Materials | Softer things (wood, plastic, foam) | Hard things (steel, titanium, metal) |

| İçin En İyisi | Big, fast cuts on soft items | Very exact, strong metal parts |

| Sertlik | Daha düşük | Çok Yüksek |

| İş Mili Hızı | Çok Yüksek | Daha düşük |

| Cutting Power | Daha düşük | Çok Yüksek |

When you need to make parts that have perfect measurements, the CNC mill is the winner, for sure. The reason is the way the machine is built. CNC mills are built to be very stiff and very heavy. This means there is almost no shaking or moving when the machine is cutting. Being steady like this is the secret to getting very exact cuts.

Mills give you the exactness needed for jobs where you cannot make a mistake. Think about a part for a car engine or a tool for a doctor. These parts must be perfect. A CNC mill can make cuts that are correct down to a very small part of a millimeter. A normal CNC router cannot be that exact.

A CNC router can still be very good at making correct cuts. For making things from wood or making signs, the exactness of a CNC router is good enough. But it is not made for the same level of tiny detail as a CNC mill. The lighter frame and faster movement of a CNC router can cause tiny shakes that change how the final cut looks. So, if your project needs the most exact cuts possible, especially in metal, you need a CNC mill.

Most simple CNC routers and CNC mills use three axes for movement: X, Y, and Z. This is called 3-axis machining. It lets the cutting tool move left-and-right, front-and-back, and up-and-down. For many projects, three axes are all you need. You can cut out flat shapes, carve on surfaces, and make parts that have some depth.

But the world of CNC can have more than three axes. This is another way that CNC mills often have more choices. You can find many CNC mills with 4 or even 5 axes. A 4th axis usually adds a turning motion to the workpiece. A 5th axis adds another tilting motion. These extra axes let the machine cut a part from almost any side. You don’t have to stop and move the workpiece yourself.

This power to cut on more axes makes the CNC mill a very strong machine for very difficult parts. It can make curved surfaces and odd angles all in one go. Some expensive CNC routers have 4 or 5 axes. But it is much more normal to see this on a CNC mill. So, if you want to make very complex 3D shapes, a multi-axis CNC mill is probably the machine you will need.

The spindle is the part of the machine that holds the cutting tool and makes it spin. The spindle and the tools that are used are another one of the key differences between CNC routers and CNC mills. A CNC router’s spindle is made to go very fast. It can spin at 20,000 RPM (revolutions per minute) or even faster. This high speed is great for cutting wood and plastic. It leaves a clean, smooth edge. The tools, which are often called router bits, are made for this kind of high-speed work.

A CNC mill has a spindle that is built for power, not just for speed. The spindle on a CNC mill is much stronger. It spins at slower speeds. This slower speed makes more torque, which is like twisting power. This power is needed to push a cutting tool through hard metal. You cannot use high speeds on steel. If you do, the tool will get too hot and break.

The cutting tools are also very different. CNC routers use router bits, which are great for cutting through wood. CNC mills use tools called end mills. These end mills are made from very hard materials. They have special shapes made to cut away small pieces of metal. If you use the wrong tool on either machine, you will get bad results and break your tools.

When you are ready to buy a machine, the price is always a big thing to think about. Usually, a CNC router costs less money than a CNC mill. You can find a small CNC router for hobbies for a few hundred dollars. Bigger, professional CNC routers for a wood shop can cost thousands of dollars. But they still cost much less than a CNC mill.

CNC mills usually cost a lot more money. The heavy parts, strong motors, and very exact parts all make the cost go up. A small CNC mill that sits on a bench can cost a few thousand dollars. A big industrial CNC milling machine can cost tens or even hundreds of thousands of dollars. The price shows what the machine can do, like heavy and exact work.

When you think about cost, you also need to think about the future. A cheap machine might not last as long or work as well. A good quality CNC machine is something you spend money on now to help you later. You need to figure out which is best for the money you have to spend and for your needs. The lower cost of a CNC router makes it a great first step for many people starting with CNC.

So, after all of this, how do you pick which machine to choose? You just need to ask two main questions: What things will you be cutting? And how exact do your cuts need to be? Let’s make it simple.

You should pick a CNC router Eğer:

You should pick a CNC freze Eğer:

Picking the right machine is very important. A CNC router is a fast machine that can do many jobs with softer materials. A CNC mill is a strong and exact machine for hard materials. Think about the work you want to do now and the work you might do later to make the best choice.

The basic steps for the software are the same for both a CNC router and a CNC mill. Both machines use computer-aided design (CAD) software to make the 2D or 3D model of the part. Then, they use computer-aided manufacturing (CAM) software to plan the paths for the cutting tool. This makes the code the machine will read. This code is called G-code.

The small things are what’s different, and these are inside the CAM software. The settings you use for a CNC router are very different from the settings for a CNC mill. For a CNC router, your CAM software will be set up for high spindle speeds and fast cutting moves. You will tell it you are using router bits and cutting materials like wood.

For a CNC mill, the CAM software settings will be about controlling the cut in hard metal. You will use slower spindle speeds but more cutting power. You will pick from a list of end mills and tell the software you are cutting metals like steel. The software programs might be the same (like Fusion 360 or Mastercam). But you use them in a totally different way based on the machine.

To finish up, let me give you the most important things to know. Here are the big differences between a CNC router and a CNC mill.

I hope this guide has made the difference between a CNC mill and a CNC router easy to understand. Now you know what you need to pick the right machine for your next great project.