Tecrübemiz ve bilgi birikimimizle Istar'ın projenize başlamanıza yardımcı olmasına izin verin!

Tasarım dosyalarınızı ve üretim gereksinimlerinizi yükleyin ve 30 dakika içinde size geri dönelim!

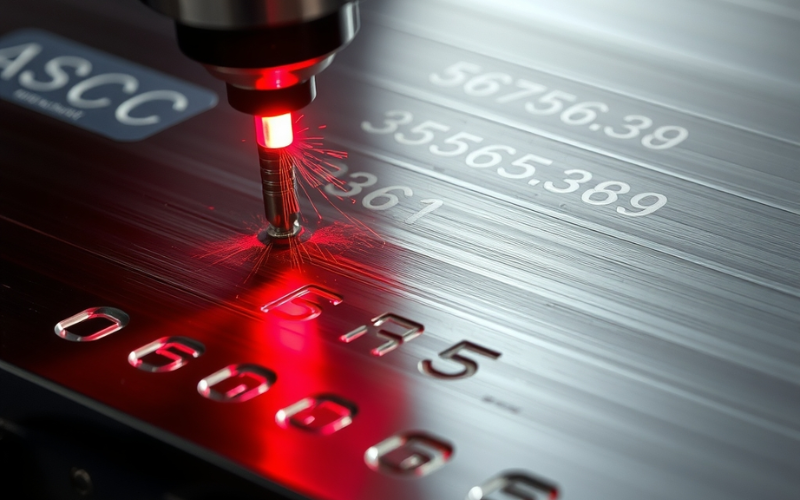

Laser etching and laser engraving do sound a lot alike, right? Many people use these words for the same thing. But I am here to tell you they are not the same at all. Knowing the difference can help you avoid problems. It can help you get the best look for your parts. This article will explain laser etching vs engraving in an easy way. I will help you know which laser marking way is right for what you need to do.

The laser etching process is a way that uses a strong beam of laser light to melt the top of a material. You can think of it like this: the strong energy from the laser beam makes a lot of heat. This heat melts only the very top layer of the part you are working on. When the melted material gets cool again, it gets a little bigger. This makes a small bump you can feel. This new feeling on the surface is the mark you see. So, when you etch something, you are not cutting into the material. You are just changing how the top looks and feels.

The laser used for this is very exact. It lets you make very clear pictures, words, or codes. The mark itself is often a new color that is different from the material you started with. For instance, when you etch some kinds of metal, you can get bright marks that look like frost on a window. On some plastics, you can get dark marks. The main thing to know about this marking way is that the laser melts the top; it does not vaporize it. The laser power is not as strong as what you would use to engrave. We often use laser etching when we need a mark that is quick and clear. This process is very fast. This makes it good for a lot of different work. You can etch many things with a good laser.

Now, we can talk about the laser engraving process. This is not like etching. Laser engraving is a process that uses a laser to take away some of the material from the top. The laser beam is so strong that it heats up the material right away. It turns the material into a gas. This is called vaporization. It cuts a little hole or groove into the material. When you engrave a part, you make a mark that goes deep into the surface. You can feel it with your finger. It is like digging a small ditch with a beam of light. A good engraver can make marks with a lot of small details.

The depth of the engraving can be changed by how strong the laser is and how fast it moves. A laser beam that is slower and stronger will engrave deeper into the material. This engraving method is great for making marks that need to stay there for years. The laser engraving process really takes away material, so the mark is tough and long-lasting. It will not get damaged easily from use. This makes laser engraving the best choice for things that will be touched or used a lot or put in rough places. The laser must be strong to engrave well. You can engrave a logo or words easily with the right kind of laser. This laser way of doing things is really cool.

I hear this question all the time. The biggest difference between the two is how the laser works on the material. To say it in a simple way:

You can think of it like working with snow. Etching is like using a looking glass to melt the very top of the snow. This makes it icy and different. Engraving is like using a strong spray of hot water to blast the snow away. This leaves a hole. That is the main difference between laser etching and engraving. The laser used to etch is not as strong. Because of this, the process is often faster than engraving.

Here is a simple table to show the main differences between laser etching vs engraving:

| Özellik | Lazer Aşındırma | Lazer Gravür |

|---|---|---|

| Süreç | Melts the top | Turns to gas and takes material away |

| Mark Type | Raised, has a texture | Deep cut or groove |

| Derinlik | Very, very thin (less than 0.001″) | Deeper (up to 0.005″ or more) |

| Hız | Very fast | Slower than etching |

| Ne Kadar Sürer | İyi | Excellent, does not wear out |

| En İyi Kullanım | Easy-to-see marks | Marks that last forever for tracking |

Knowing these differences between laser processes is important for choosing the right laser for your work. Both laser etching and laser engraving are great tools for making marks. But they are used for different reasons. You have to pick if you want to etch or engrave.

This is a very good question. The depth of the mark is a big thing to think about when picking between etching and engraving. Like I said before, when you etch a surface, you are only changing the very top. The cut depth for laser etching is very, very thin. It is usually less than 0.001 inches. It is more like changing the skin of the material than making a cut. The idea is to change how the top looks, not to dig into it. You do not need laser etching to be deep. You just need it to be clear.

Laser engraving, on the other hand, is all about being deep. The engraving depth can change a lot. It depends on the laser power, the material, and how long the laser stays in one place. A normal laser engraved mark might be about 0.003 to 0.005 inches deep. But with strong engraving machines, you can do deep engraving that is much deeper. This depth is what makes engraving so long-lasting. The mark is actually cut into the workpiece. This means it cannot be rubbed away. When you need to engrave something forever, depth is important. A strong laser can engrave very deep. The process that uses a laser for engraving is very exact.

So, when is it the right time to use laser etching? I say you should use it when you need a mark that is easy to see, and you need it made quickly. The laser etching process is very fast. This makes it perfect for places that make a lot of things quickly. It is great for putting a logo, barcode, or QR codes on parts. The marks it makes are easy to read for people and for scanners. The laser etched mark is often a new color. This is what makes it easy to see.

For example, in the aerospace or medical fields, parts need to be clearly marked. A laser can etch a part number on stainless steel or titanium. The mark that is made is bright and clear against the darker metal. You also see laser etching on free gifts with company names on them and on electronics. It’s a great way to make a mark for adding a company’s logo on something without hurting the part. If you just need a mark on the top, you should etch it. This marking process is quick and does a good job. The laser is the right tool for the job.

Now, when does laser engraving work the best? The simple answer is when you need it to last for a very long time. If the part you mark will get rubbed a lot, have chemicals on it, or be in a rough place, you need to engrave it. Laser engraving offers a mark that will last forever because it is cut deep into the part’s top. This is very important for part traceability in areas like the automotive and aerospace fields. Think about a very important part of a car engine. The serial numbers on it must last as long as the car does. A mark that is not deep could rub off. A deep engraving will not.

You should also pick laser engraving when you want it to look and feel a certain way. The depth of an engraved mark makes it look very good and well-made. This is why you see laser engraving on nice jewelry, awards, and gifts with a person’s name on them. The laser cuts away the material to create deep, lasting marks. So, if you need a mark that can last through anything, laser engraving is the best choice. A strong laser can engrave on almost any material, from metal to wood to plastic. This laser way of doing things is very strong and reliable.

Yes! Laser etching and engraving are the ones you see the most. But they are part of a big group of laser marking processes. It is good to know about some others. One important one is laser annealing. This is a special way of doing it used mostly on metal surfaces, especially stainless steel. Instead of melting or making the material a gas, laser annealing uses a less strong laser to heat the metal. This heat makes a change happen under the surface. What you get is a mark that lasts forever. It is smooth and dark, and the surface still feels smooth. It creates black marks that are very clear.

Another process is called foaming. It is used on some kinds of plastic. The laser melts the plastic. This makes little bubbles of gas that get stuck inside as it cools down. These bubbles make a bumpy mark that is a light color. Both of these are kinds of laser marking, just like etching and engraving. The world of laser technology is very big. Each laser marking process has its own good points. Choosing the right one is based on the material and what you want the mark at the end to look like. The goal of any laser marking is to create permanent markings. A laser marker can do all of these laser processes.

Yes, for sure. This is one of the most common uses for laser systems. Both laser etching and laser engraving work great on metal. From what I have seen, a fiber laser is often the best pick for marking on most kinds of metal. This includes steel, aluminum, brass, and titanium. A fiber laser is a special kind of laser. It works well and is very strong. This makes it perfect to engrave or etch tough materials.

When you etch metal, you can get a really nice mark that is easy to see. I have seen it used to make amazing pictures on all kinds of things, from medical devices to tools made for a special job. When you engrave metal, you get a deep mark that lasts forever. This is perfect for uses in factories, like telling parts apart in the automotive industry. You can engrave serial numbers that will never go away. Some jobs need a laser to sandblast the top first to get it ready to be marked. The laser can work on many different kinds of metal. It makes a clean and exact mark every time. This laser works hard and is very reliable. The laser marker is great for metal.

I really like laser marking. It has so many good things compared to older ways like stamping, chemical etching, or using printed labels. One of the biggest benefits of laser technology is that it is very exact. A laser beam can create marks that are very clear and have a lot of detail. You can engrave tiny words or logos with many parts, and they are perfectly clear. This laser exactness is better than anything else. The laser is a tool that can do very careful work.

Another great thing about it is that it is a non-contact process. This means it does not touch the material. Unlike etching tools that actually touch the material, a laser does its job with a beam of light. This means there is no wear and tear on the tool. Also, it is less likely to break parts that are easy to damage. The laser is also very fast. It is easy to set up with machines, which is great for making things in a factory. Last, laser marking lasts forever. It does not matter if you etch a mark on the top or engrave a deep one. That mark is not going anywhere. This ability to last a long time makes laser technology perfect for part traceability. Using a laser is just a better way to do part marking.

We have talked about a lot of things. So, how do you make your choice in the laser etching vs laser engraving question? I tell people to ask themselves three easy questions:

My advice is to think about what you want to do in the end. Are you making an ID that lasts forever for an automotive part? Or are you adding a logo to a product that is ready to sell? Answering that question will help you choose the right laser process. The laser beam to create the mark can be changed for either process. Both laser marking ways are powerful. The laser is a tool you can use for many things.