Precision CNC Machining Company

Top 5 CNC Machining Manufacturer in China: Direct From Your Factory Partner

Leverage our extensive experience and advanced CNC technology for your custom metal and plastic parts. As a direct manufacturer, not a broker, we utilize a wide range of CNC machines, including multi-axis machining centers, to deliver complete machining solutions from prototype to production parts.

Advantages of Direct CNC Machining Manufacturer

Direct CNC Manufacturer

Eliminate middleman costs and communication delays. Work directly with the source utilizing our comprehensive machine park.

Broad Capabilities

Extensive machining capabilities across diverse materials (metal, plastics, exotics) and CNC machine technologies.

20+ Years Proven Expertise

Decades of hands-on experience translating complex designs into high-quality cnc parts.

1000 skilled machinists and operators

30000 square meters of modern plant

300 Automated CNC Machining Machines

Istar's Core CNC Machining Services

Learn about precision manufacturing solutions from top CNC machining shop. From CNC milling and turning to specialized processes, we utilize advanced technology to produce accurate, high-quality custom parts for your projects.

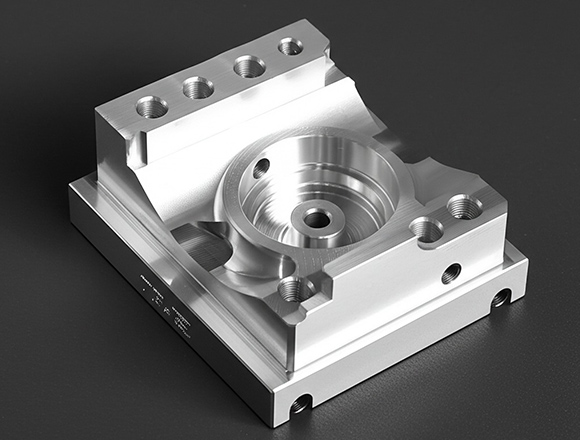

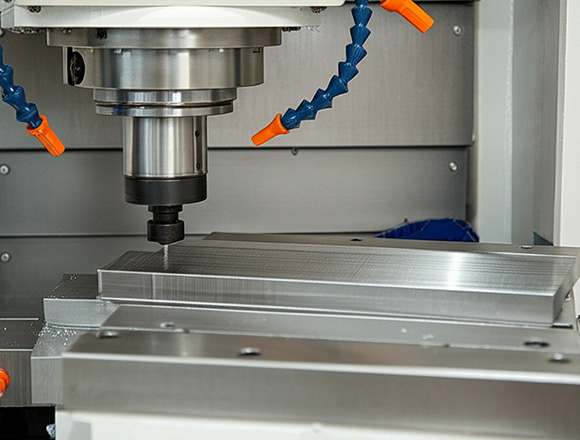

CNC Milling Service

Precise material removal using rotating cutters on computer-controlled machines to create complex shapes, slots, and features.

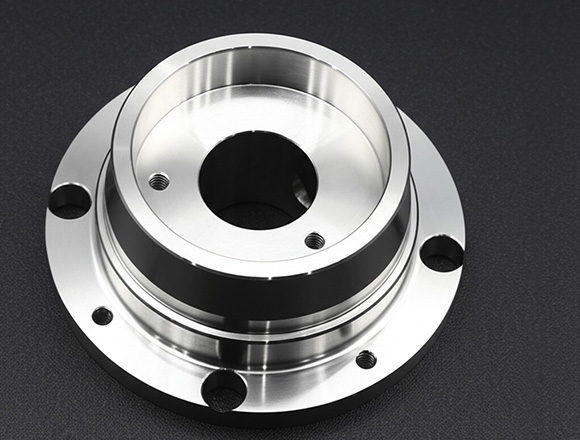

CNC Turning Service

Shaping material by rotating a workpiece against a cutting tool on a CNC lathe. Ideal for cylindrical parts.

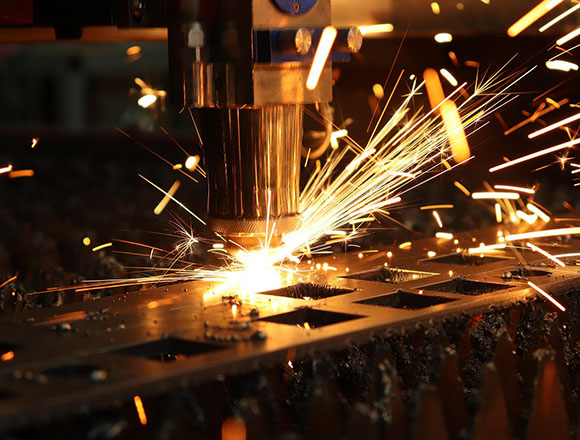

CNC Cutting Service

Precision cutting of various materials like metal, wood, and plastic using advanced computer-controlled (CNC) machines for accurate results.

CNC Routing Service

Utilizing CNC routers to precisely shape materials like wood, plastics, and composites for intricate designs and custom components.

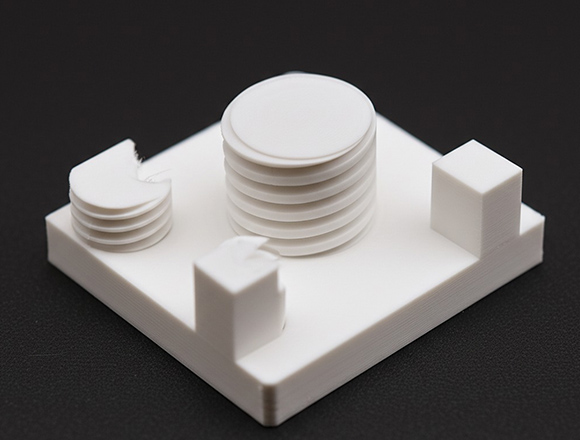

CNC Prototype Service

Rapidly create accurate, functional prototypes using CNC machining. Perfect for testing designs and validating concepts before full production.

CNC Parts Machining

Precision manufacturing of custom parts and components from various materials using CNC milling, turning, and other machining processes.

CNC Grinding Service

High-precision grinding using CNC machines. Ideal for achieving fine surface finishes and extremely tight tolerances on hardened materials.

CNC Carving Service

Creating intricate 3D designs, detailed reliefs, and complex shapes using CNC technology, perfect for artistic and decorative applications.

Diverse CNC Machining Materials: From Metal Alloys to Advanced Plastics

Different materials are better for different jobs. Here’s what works best:

Metals

Selecting the right material is crucial for component performance. Our CNC machining service boasts extensive experience working with a wide spectrum of CNC machining materials. Our cnc machining factory’s expertise in metal machining is particularly strong, encompassing:

Aluminum

Stainless Steel

Titanium

Brass

Other Metals We Work With

Aluminum

Aluminum alloys are valued for their excellent strength-to-weight ratio, good corrosion resistance, and high machinability. They are widely used across many industries.

- 6061 Aluminum: A versatile and popular grade offering good mechanical properties and weldability. Often used for structural components, bicycle frames, and automotive parts where light weight and adequate strength are needed.

- 7075 Aluminum: A high-strength alloy, significantly stronger than 6061, commonly used in aerospace applications (like aircraft structures) and high-stress parts where weight saving is critical.

Our team at Istar Machining provides expert aluminum CNC machining services for precise results.

Stainless Steel

Stainless steel alloys offer exceptional strength, durability, and excellent corrosion resistance, making them ideal for demanding applications and harsh environments.

- 304 Stainless Steel: The most common grade, known for its good corrosion resistance and formability. Widely used in kitchen equipment, food processing machinery, and general-purpose applications.

- 316L Stainless Steel: Offers superior corrosion resistance, particularly against chlorides and acids. Ideal for marine applications, medical implants, and chemical processing equipment.

Rely on our steel CNC machining capabilities for high-quality stainless steel components.

Titanium

High strength-to-weight ratio, excellent corrosion resistance. Critical for aerospace cnc machining and medical implants.

Titanium alloys, particularly Ti-6Al-4V (Grade 5), provide an exceptional combination of high strength, low weight, and outstanding corrosion resistance. It is also biocompatible.

- Ti-6Al-4V (Grade 5): Frequently used in aerospace components, high-performance automotive parts, and medical implants due to its superior properties, despite being more challenging and costly to machine.

Our specialists in titanium CNC machining have the expertise to handle this advanced material.

Brass

Brass is an alloy of copper and zinc known for its good machinability, electrical conductivity, corrosion resistance, and attractive appearance.

- Commonly used for electrical connectors, plumbing fittings, decorative hardware, and musical instruments where its combination of properties and aesthetic appeal is advantageous.

We produce functional and visually appealing brass CNC machined parts.

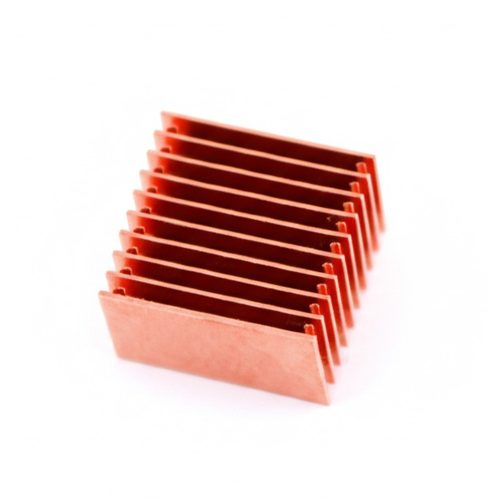

Other Metals We Work With

- Copper: Excellent electrical and thermal conductivity, used in electrical components and heat exchangers.

- Tool Steel: High hardness and wear resistance, used for cutting tools, dies, and molds.

- Inconel: A nickel-chromium superalloy that maintains strength at extreme temperatures, used in aerospace engines and heat-treating applications.

- Magnesium: Extremely lightweight (even lighter than aluminum), used where minimal weight is paramount.

Plastics

Here is an overview of common plastic materials we utilize at Istar Machining, along with their key features and uses:

PEEK

Delrin (POM)

PTFE (Teflon)

Polycarbonate (PC)

Nylon 6/6

UHMW-PE

Acrylic (PMMA)

PVC

PEEK

Key Properties / Advantages

- High temperature resistance (up to 260°C / 500°F)

- Excellent mechanical strength (~96.5 MPa / 14,000 psi tensile)

- High chemical resistance

Common Applications

- Aerospace components

- Medical instruments

- Semiconductor industry

Highlights / Noteworthy Features

- Considered a high-performance plastic, excels in demanding thermal and chemical environments.

Delrin (POM)

Key Properties / Advantages

- Low friction coefficient (Naturally lubricious)

- High dimensional stability

- Food grade compliant (specific grades)

Common Applications

- Gears

- Bearings

- Sliding components

- Automotive fuel systems

Highlights / Noteworthy Features

- Excellent machinability, ideal for precision parts requiring stiffness and low friction

PTFE (Teflon)

Key Properties / Advantages

- Extremely low friction (Non-stick surface)

- Wide operating temperature range (-200°C to +260°C)

- Excellent electrical insulator

Common Applications

- Seals

- Gaskets

- Linings

- Chemical processing components

Highlights / Noteworthy Features

- Renowned for its chemical inertness, non-stick properties, and wide temperature tolerance

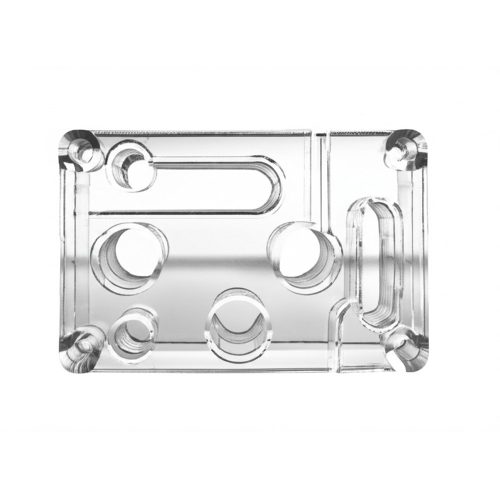

Polycarbonate (PC)

Key Properties / Advantages

- High impact strength (Very tough)

- Optically clear

- Good UV resistance

Common Applications

- Safety glazing

- Machine guards

- Automotive lighting

- Enclosures

Highlights / Noteworthy Features

- Combines transparency with exceptional toughness, often used as a “clear metal” substitute

Nylon 6/6

Key Properties / Advantages

- Good wear resistance

- High mechanical strength (~85.5 MPa / 12,400 psi tensile)

- Absorbs moisture (can affect stability)

Common Applications

- Bearings

- Bushings

- Rollers

- Wear pads

- Structural parts

Highlights / Noteworthy Features

- A versatile and durable engineering plastic, common in mechanical wear applications

UHMW-PE

Key Properties / Advantages

- Exceptional abrasion resistance

- Very low coefficient of friction

- Food grade compliant

Common Applications

- Food processing equipment

- Conveyor parts

- Marine components

Highlights / Noteworthy Features

- Superior wear resistance, especially in sliding applications, even in wet conditions

Acrylic (PMMA)

Key Properties / Advantages

- Excellent optical clarity

- Good scratch resistance (relative)

- Machines cleanly, polishes well

Common Applications

- Displays

- Light pipes

- Sight glasses

- Decorative panels

Highlights / Noteworthy Features

- Often used as a lightweight, shatter-resistant alternative to glass with high clarity

PVC

Key Properties / Advantages

- Good flame resistance

- Good chemical resistance

- Low cost

Common Applications

- Pipe fittings

- chemical tanks

- Electrical insulation

- Housings

Highlights / Noteworthy Features

- A cost-effective and versatile plastic offering good chemical and fire resistance properties

Our Advanced 5-Axis CNC Milling

Our new 5-axis CNC milling machines can move a part on three straight lines (X, Y, Z) and two turning circles at the same time. This lets us cut difficult shapes, curved surfaces, and tricky designs all at once, without having to set up the part again.

How Accurate We Can Be: Down to ±2-5 micrometers on our best machines; surfaces can be made as smooth as Ra 0.2 micrometers by using the right tools and machine settings.

How Fast the Machine Spins: 12,000–40,000 rpm; our machines can hold up to 120 different tools, making it easy to switch between jobs.

What We Use It For: Parts for airplanes like impellers, medical parts like acetabular cups for hips, turbine blades, and very precise parts for cameras and lenses.

Multi-Axis Turning & Swiss-Type Machining

Istar’s Swiss-type lathes are great for making long, thin parts that need to be very exact (like medical bone screws and watch parts), with accuracy as good as ±1 micrometer. Our multi-axis turning centers use spinning tools and extra spindles to finish complicated parts in one go. This saves time and prevents mistakes.

What We Use It For: Hydraulic valve spools, special screws for airplanes, and large orders of car parts.

Our Electrical Discharge Machining (EDM)

Istar provides Wire EDM and Sinker EDM services, which are especially good for materials that are hard to cut.

Wire EDM: Can get an accuracy of ±1-2 micrometers and make surfaces as smooth as Ra 0.1 micrometers. It’s perfect for hard materials like tool steel, tungsten carbide, and Inconel.

Sinker EDM: Used to make deep holes, sharp inside corners, and tiny details in molds. Even though it’s slower than normal cutting, EDM can make shapes that regular tools can’t.

Precision Grinding (CNC & Manual)

Istar’s CNC grinding machines can get to super-high accuracy (±0.5 micrometers) and create very smooth surfaces (Ra < 0.05 micrometers). This is very important for bearing raceways, optical parts, and precision molds. Grinding is often used as a finishing step for hard materials (like ceramics or hardened steel) or to get the final size just right after heat treatment.

Proven Experience Across Demanding Industries

As a top 5 CNC machining manufacturer in China, Istar successfully partners with clients in critical sectors like aerospace, medical, and automotive, delivering precision CNC machined parts that meet stringent quality standards and complex technical requirements.

We Use Modern Machines to Make Your Precision Parts

The most important part of our CNC machining service is making high-quality, accurate parts for you. We can do this because our factory has invested in the latest equipment. We have all the right machines to handle even your most difficult and detailed projects.

Istar Client's Feedback

"Istar delivered complex milled aluminum components that met our tight aerospace tolerances. Communication was clear, and their quality documentation was thorough. Lead time was slightly longer than initially quoted on one batch, but they kept us informed."

Michael Smith

Aerospace Engineer

"We used Istar for prototyping our PEEK implant components. Their precision was excellent, and they handled the material expertly. Pricing was very competitive, which was crucial for our budget. Turnaround was impressively fast."

Julia Clarke

Medical Device Startup

We rely on Istar for mid-volume runs of steel transmission parts. They consistently deliver reliable quality at a scale few others can match for the price. Their team is professional, though sometimes requires very specific technical details upfront."

Jacob Adams

Automotive Parts Purchaser

"Istar provided great value on a large order of custom stainless steel fixtures. The finish quality was good, and parts were dimensionally accurate across the batch. Shipping coordination to Europe was handled smoothly."

David Williams

Industrial Equipment Manufacturer

"Needed intricate parts with multiple setups. Istar's 5-axis capabilities were key. Their engineering team provided useful feedback on manufacturability, saving us potential issues. Response times were generally good, considering the time difference."

Noah Davis

Robotics Company

Ready to Start Your Next CNC Machining Project?

Let Istar Machining’s 20+ years of expertise and comprehensive machining capabilities bring your designs to life. Use CNC machining with a proven partner. Request a quote today for competitive pricing and expert support for your custom parts.

WhatsApp / Phone

+86 17744915606

Address

303, Building 3, Xinggang Tongchuanghui, Fuhai Street, Baoan District, Shenzhen, Guangdong, China 518103

Frequently Asked Questions

Navigating the specifics of CNC machining can raise questions. Here are answers to some common CNC machining FAQs:

We routinely hold tight tolerances for cnc machining, often down to ±0.0002 inches (±0.005 mm), depending on the material and geometry. Our precision cnc machining capabilities are a core strength.

Lead times vary based on complexity, quantity, and material availability. We offer expedited options for urgent needs, including rapid cnc machining. We strive to provide the best cnc turnaround times possible.

We accept most standard CAD formats (e.g., STEP, IGES, SLDPRT, DXF).

Our website offers insights, and our expert team is always available to discuss your project and the optimal machining solutions.

Yes, we support the full product lifecycle, from initial prototypes and production parts through to high-volume manufacturing. Explore our cnc prototype machining services.

As a top factory, we adhere to strict quality control (QC) protocols, often including ISO 9001 certification, CMM inspection, material certifications, and detailed QC reports per project.

Lead times vary based on complexity, quantity, and material availability, but our scale allows for competitive turnaround, often ranging from 1-4 weeks for standard projects. Expedited options are available.

Yes, our facility is equipped for flexibility. We support rapid prototyping needs as well as high-volume production orders with consistent quality.

Our scale, advanced technology, optimized processes, and efficient supply chain management in China allow us to offer highly competitive pricing without compromising on quality.

We take IP protection seriously. We readily sign Non-Disclosure Agreements (NDAs) and maintain secure systems to safeguard your designs and confidential information.

Latest from Blog

Explore our blog for insights, technical articles, and industry news covering CNC machining advancements, applications in sectors like energy and robotics, and tips for optimizing your parts.

Mounting Brackets: Where Designs Either Quietly Work Or Quietly Fail

Most mounting brackets do not fail because the metal was weak. They fail because a few small design and…

CNC vs Sheet Metal Manufacturing: How Mature Teams Decide

Most of the time the choice is simple: if the part is thick, 3D, and tolerance-critical in low or…

6061-T6 Aluminum: The Workhorse You Rely On

If you strip away marketing and catalog copy, 6061-T6 is simply the grade you choose when you want aluminum…