Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

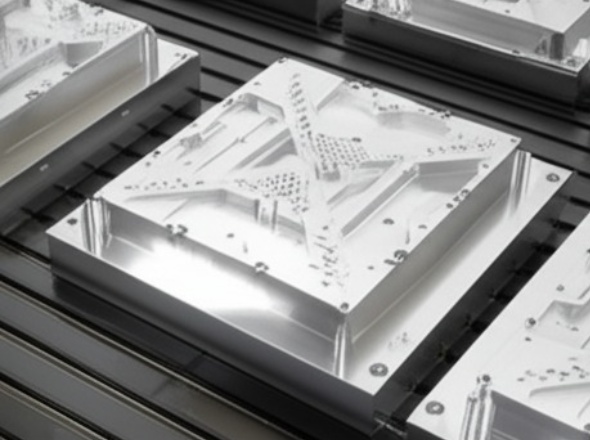

Are you looking for a way to make perfect parts with both sides looking great? 2-sided CNC routing is the answer! At Istar Machining, we help you make amazing products with our cutting-edge machines.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

2-sided CNC routing is a super cool way to cut and shape materials on both sides without messing up. Instead of flipping your part by hand (which can cause mistakes), our special machines work on both sides with perfect matching.

As one of the top 5 CNC machining factories in China, our precision CNC machining gives you parts that fit together perfectly every time.

Two-sided CNC routing is compatible with a wide variety of materials. Below is a detailed list of materials commonly used for 2-sided CNC routing, categorized for clarity:

Metals

(Common Grades: 6061, 7075, 5052, 2024) is lightweight, corrosion-resistant, has excellent thermal and electrical conductivity, and is very machinable.

(Common Grades: 304, 316, 440C) offers excellent corrosion resistance, high strength, and durability. Different grades offer varying levels of machinability and resistance to specific environments.

(Common Grades: A36, 1018) is a cost-effective and versatile material with good weldability and machinability. It’s strong and can be easily finished.

(e.g., Chrome Moly, Tool Steel) offers enhanced strength, hardness, wear resistance, and heat resistance compared to mild steel. Specific alloys are chosen based on the required properties.

(Common Alloys: C260, C360) is known for its good machinability, corrosion resistance, electrical conductivity, and aesthetic appeal.

(Common Grades: Grade 2, Grade 5) is a lightweight metal with exceptional strength-to-weight ratio, excellent corrosion resistance, and biocompatibility.

Offers excellent electrical and thermal conductivity, good corrosion resistance, and machinability.

Plastics

A transparent and rigid plastic with good optical clarity, weather resistance, and machinability.

A strong and impact-resistant transparent plastic with good heat resistance.

A common thermoplastic known for its good impact resistance, toughness, and machinability.

A high-strength, stiff engineering thermoplastic with excellent wear resistance, low friction, and good dimensional stability.

A tough and wear-resistant thermoplastic with good chemical resistance and low friction.

A strong, durable, and chemical-resistant thermoplastic with good impact resistance.

An extremely tough and abrasion-resistant thermoplastic with a very low coefficient of friction.

Known for its extremely low coefficient of friction, excellent chemical resistance, and high-temperature resistance.

Wood & Composites

(e.g., Maple, Oak, Walnut): Dense and durable woods with attractive grain patterns, suitable for structural and aesthetic applications.

(e.g., Pine, Fir, Cedar): Less dense and generally more affordable woods, easier to machine and suitable for various construction and crafting purposes.

An engineered wood made from thin layers of wood veneer glued together, offering good strength and stability.

An engineered wood product made from wood fibers glued under heat and pressure, providing a smooth and consistent surface.

A tough and wear-resistant thermoplastic with good chemical resistance and low friction.

(e.g., Garolite, Bakelite): A durable and electrically insulating composite material made from layers of fabric or paper bonded with resin.

Lightweight and extremely strong materials made from carbon fibers embedded in a resin matrix.

Strong and corrosion-resistant materials made from glass fibers embedded in a resin matrix.

Foam & Other Materials

(e.g., Polyurethane, Polystyrene): Lightweight materials with good insulation properties, suitable for prototyping, packaging, and insulation.

A durable and weather-resistant closed-cell polyurethane foam, excellent for signage and dimensional lettering.

A natural material with flexibility and durability, suitable for various decorative and functional applications.

Why customers love it: Its natural beauty and durability make it a popular choice for handcrafted items.

Make cabinet doors with fancy grooves that match on both sides. Wooden parts fit together perfectly!

Make lightweight aluminum brackets for planes and rockets. Our aerospace CNC machining helps parts fly high!

Create double-sided signs where both sides line up perfectly. Great for stores and businesses!

While many materials can be used for 2-sided CNC routing, successful execution depends on factors such as:

Our process is simple but super smart:

Our machines use laser guides and special pins to make sure both sides match perfectly. No more parts that don't fit right!

We can make 500+ parts per day using machines that work around the clock. Need parts fast? We've got you covered!

Our smart software cuts parts using the least material possible, saving up to 30% compared to other methods.

Both sides of your part will look amazing with the same smooth finish.

Our 3-axis CNC routers are optimized for machining flat sheet materials. Utilizing precise registration methods, we accurately machine features on both sides of the workpiece. This makes them great for flat parts with both sides machined, such as panels, signage, and structural components, delivering cost-effective solutions with high accuracy for less complex, double-sided geometries.

Equipped with advanced 5-axis capabilities, our machines can handle complex 3D shapes involving compound curves and angles up to 45° (and beyond). This allows for machining multiple faces, including edges and angled features, often in a single setup. It significantly enhances efficiency and precision for intricate components, molds, and prototypes requiring multi-sided access.

Our machines feature a versatile spindle power range of 3-15 kW. This enables efficient and precise cutting everything from soft wood and plastics to harder materials like composites and non-ferrous metals (like aluminum). This ensures sufficient torque and cutting force for optimal material removal rates and excellent surface finishes across diverse applications, including demanding 2-sided jobs.

With an adjustable speed range of 10,000-24,000 RPM, we precisely match the spindle speed to the specific material and tooling requirements. This optimization ensures clean cuts, prevents material burning, extends tool life, and results in superior surface finishes – achieving the perfect cut every time for both roughing and finishing operations on either side of your part.

At Istar Machining, we focus on high-precision, custom CNC machining that makes your ideas come to life. Our CNC routing services deliver perfect parts every time.

Need more than routing? Check out our 5-axis machining for the most complex parts possible!

Contact us today to get your perfect two-sided parts made right!

Upload your CAD files (like STEP or IGES format)

We'll tell you the price and timeline within 1 hour

Our skilled machinists program the CNC machines

Every part is inspected before shipping

Your parts arrive on time, ready to use

Yes! We can handle materials as thin as 1/8 inch without breaking or bending them.

Absolutely! Our setup works great for making just a few parts or thousands of them.

We can route pieces up to 5 feet by 10 feet with our largest machines.

We use special computer programs and alignment pins that are accurate to within 0.005 inches – that’s thinner than a human hair!

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or