Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

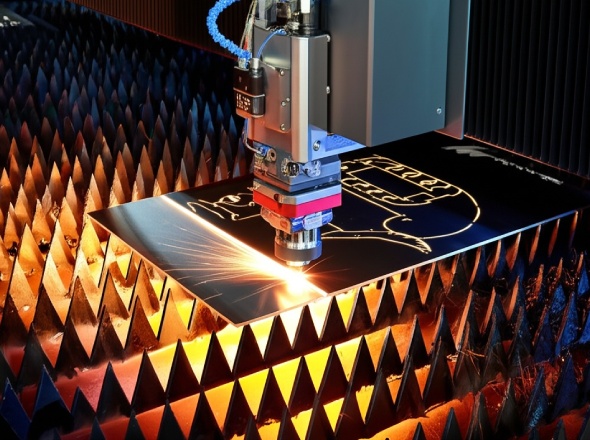

When you need parts cut with perfect precision, 2D & 3D CNC cutting might be just what you’re looking for. At Istar Machining, we use smart computer-controlled machines to cut materials exactly how you want them. Let’s look at what this technology can do for your next project!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

For thin materials that need very precise cuts, we use laser CNC cutting. This works great for metals, plastics, and wood up to certain thicknesses.

When cutting thicker metals, plasma CNC cutting is often the best choice. It uses a high-temperature plasma arc to cut through even very thick steel.

Water jet CNC cutting uses extremely high-pressure water (sometimes mixed with abrasive particles) to cut materials. It works well for materials that might be damaged by heat.

Our CNC cutting service can work with almost any material you need. Here’s what we commonly cut

Metals

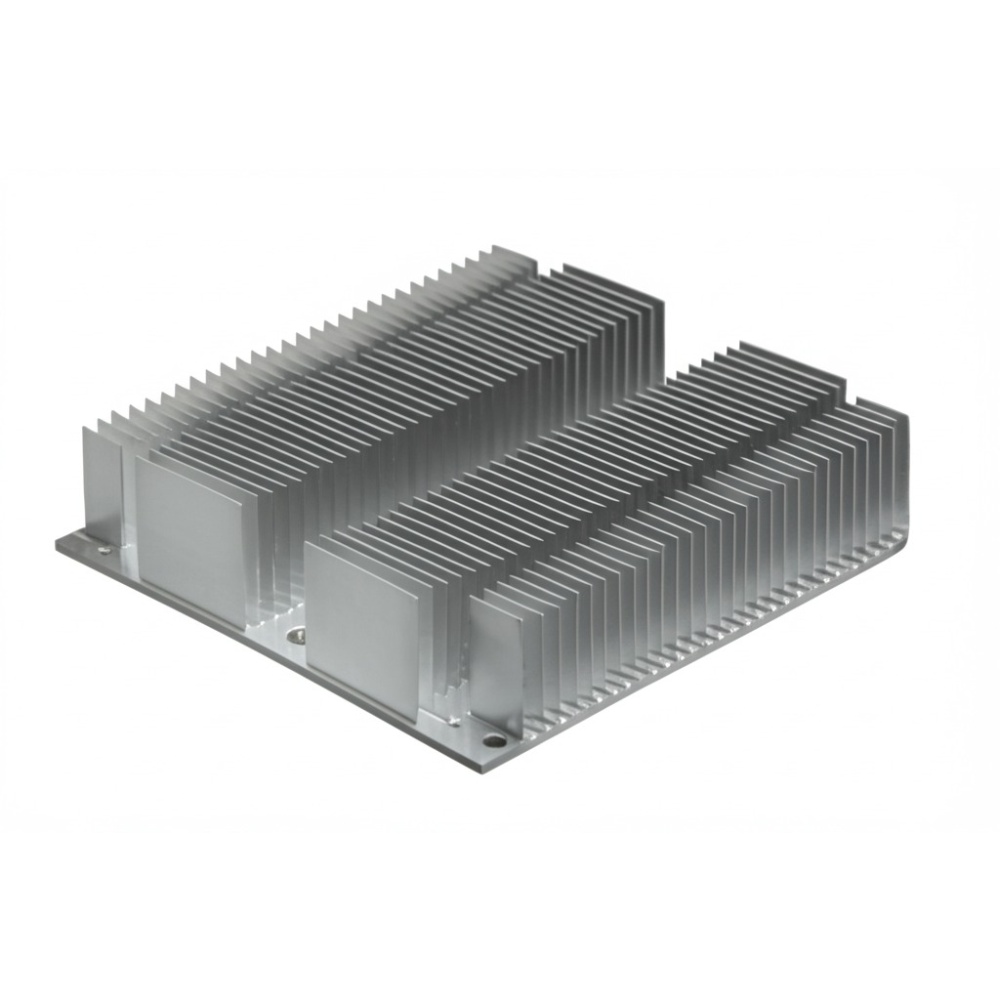

A lightweight metal prized for its excellent strength-to-weight ratio, corrosion resistance, and outstanding machinability.

Common Grades: We frequently process 6061-T6 (highly versatile, good strength, weldable), 7075-T6 (high strength for aerospace/performance parts), 5052-H32 (excellent corrosion resistance, good formability, marine applications), and MIC-6 (cast tool plate, stable for precision fixtures).

Applications: Ideal for aerospace components, automotive parts, enclosures, heatsinks, jigs, fixtures, and intricate 2D/3D decorative elements.

Known for exceptional strength, durability, and superior corrosion resistance, suitable for demanding environments.

Common Grades: We commonly cut 304/304L (most common, food grade, general purpose), 316/316L (enhanced corrosion resistance, especially against chlorides, marine/medical), and 303 (free-machining variant for easier processing).

Applications: Perfect for medical devices, food processing equipment, marine hardware, architectural features, chemical processing parts, and robust 2D/3D mechanical components.

A cost-effective and strong ferrous metal offering good machinability and weldability, forming the backbone of many structures.

Common Grades: Typical grades include 1018 (low carbon, excellent for general machining and case hardening), A36 (common structural steel), and 1045 (medium carbon, higher strength, can be heat-treated).

Applications: Widely used for brackets, machine frames, base plates, jigs, fixtures, shafts, and general 2D/3D fabrication. Note: Requires protective coating (e.g., painting, plating) to prevent rust.

An alloy of copper and zinc, valued for its excellent machinability (“free-cutting”), good corrosion resistance, and attractive appearance.

Common Grades: The most frequently machined grade is C360 / CZ121 (Free-Cutting Brass) due to its superior chip-breaking properties. We also handle others like C260 (Cartridge Brass).

Applications: Often chosen for decorative hardware, plumbing fittings, musical instrument parts, electrical connectors, bushings, and custom 2D/3D accents.

Prized primarily for its exceptional electrical and thermal conductivity, though softer and more challenging to machine than brass.

Common Grades: We typically machine C110 (ETP – Electrolytic Tough Pitch), the most common grade, and sometimes C101 (OFHC – Oxygen-Free High Conductivity) for critical applications.

Applications: Ideal for electrical components (busbars, contacts), heat sinks/exchangers, grounding straps, and some plumbing or artistic 2D/3D uses.

Our capabilities extend beyond the most common metals listed.

Examples: We can often source and process materials such as Titanium (e.g., Grade 2, Grade 5/Ti-6Al-4V), various Bronze alloys (e.g., C932 Bearing Bronze, C954 Aluminum Bronze), Tool Steels (e.g., A2, D2, O1), Magnesium alloys, Nickel alloys (e.g., Inconel®, Monel®), and more.

Action: Please contact us with your specific material grade and project requirements to discuss feasibility.

Plastics

Offers excellent optical clarity (often a glass substitute), UV/weather resistance, and comes in many colors and finishes.

Common Types: We work with both Cast Acrylic (superior optical quality, machines cleanly, better for engraving/3D work) and Extruded Acrylic (better thickness tolerance, more cost-effective, good for general 2D cutting). Common brands include Plexiglas®, Perspex®.

Applications: Perfect for signage, retail displays, light guides, protective barriers, machine windows, artistic projects, and detailed 2D/3D designs.

Renowned for its incredible impact strength (virtually unbreakable), high temperature resistance, and good clarity.

Common Types: Available in General Purpose (GP) sheets and often specified as Machine Grade (MG) Polycarbonate which has lower internal stress, ideal for heavy machining to prevent cracking or crazing. Common brands include Lexan™, Makrolon®.

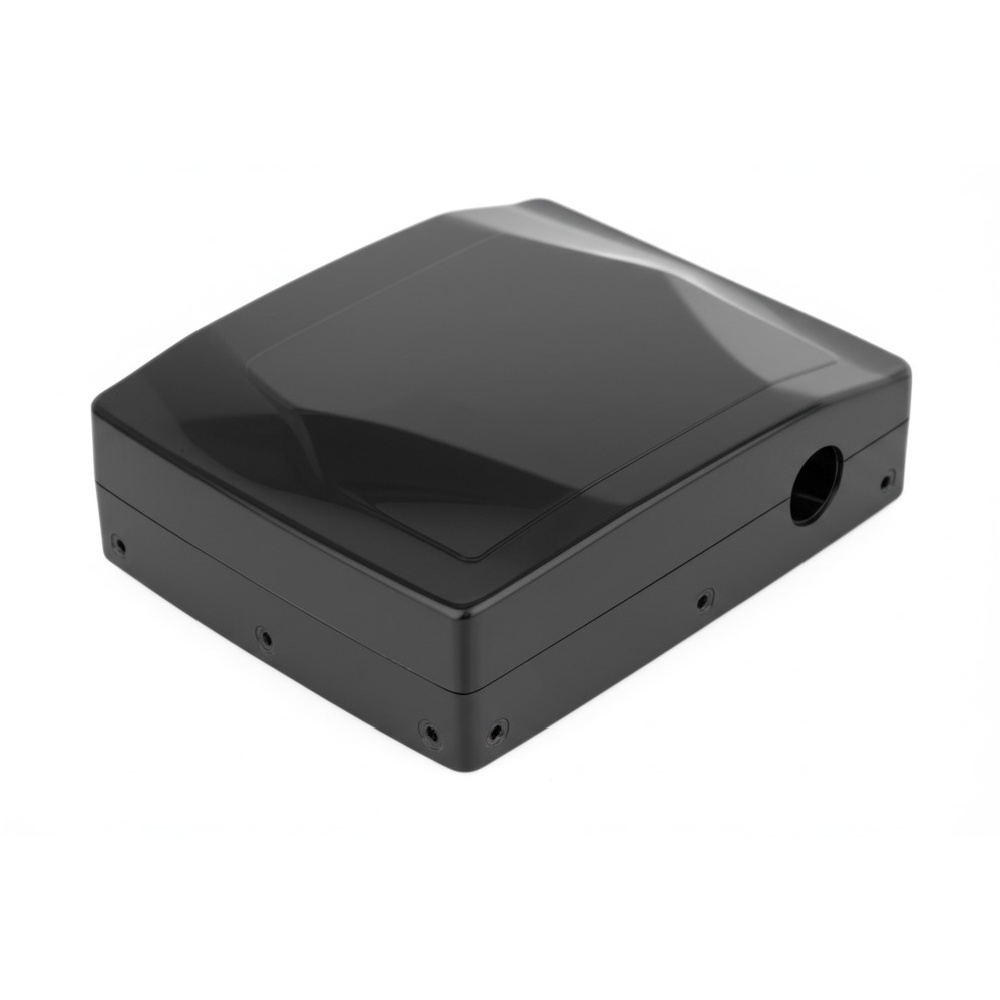

Applications: Ideal for machine guards, safety glazing, security components, durable enclosures, electronic housings, and robust 2D/3D prototypes requiring extreme toughness.

A common, rigid, and tough thermoplastic known for good impact resistance (especially at lower temps) and ease of machining, gluing, and painting.

Common Types: We typically cut General Purpose or Machine Grade ABS sheets. Available in various textures and colors.

Applications: Frequently used for electronic enclosures, automotive interior trim, instrument panels, prototypes (especially for form/fit testing), and consumer goods requiring durability in 2D or 3D forms.

Characterized by excellent wear resistance, high tensile strength, low friction coefficient, and good chemical resistance.

Common Types: Includes Nylon 6 and Nylon 6/6 (most common, extruded or cast). Specialty grades like MDS-filled (Molybdenum Disulfide for enhanced lubricity) or Glass-filled (increased rigidity and strength) are also machinable.

Applications: Ideal for gears, bearings, bushings, wear pads, rollers, seals, and structural 2D/3D components demanding durability. Note: Consider moisture absorption and its effect on dimensional stability in design.

A high-performance engineering thermoplastic offering excellent dimensional stability, high stiffness, low friction, fatigue resistance, and outstanding machinability for smooth finishes.

Common Types: We process both Acetal Homopolymer (POM-H), commonly known by the brand name Delrin®, offering slightly higher mechanical properties, and Acetal Copolymer (POM-C), offering better chemical resistance and less centerline porosity.

Applications: Ideal for precision gears, bearings, rollers, jigs, fixtures, electrical insulators, fuel system components, and complex 2D/3D parts requiring tight tolerances.

Our CNC capabilities cover a wide range of other engineering and commodity plastics.

Examples: Including HDPE (High-Density Polyethylene), UHMW / UHMW-PE (Ultra-High Molecular Weight Polyethylene – excellent wear/abrasion resistance), PEEK (high temp/chemical resistance), PTFE (Teflon® – extremely low friction, chemical inertness), PVC (Polyvinyl Chloride – good chemical resistance, low cost), PETG, Polypropylene (PP), Polystyrene (PS), and various composites (e.g., G10/FR4).

Action: Please contact us with your specific plastic type and project details to confirm capability.

For those who like to know the specifics, here are the technical details of our CNC cutting services:

Cutting Area

Our standard machines can handle materials up to 4′ x 8′ (that’s about the size of a sheet of plywood). For bigger projects, we have large CNC machining options too.

Spindle Power

We use spindles ranging from 5HP to 15HP, depending on what material we’re cutting. Harder materials need more powerful spindles.

Software

We use advanced software like Mastercam and Vectric to create perfect cutting paths for your designs.

Accuracy

Our machines can achieve tolerances of ≤0.1mm. This means your parts will be extremely accurate.

Let’s compare these two cutting methods:

Feature | 2D Cutting | 3D Cutting |

Complexity | Flat designs like signs and plates | Complex shapes like molds and reliefs |

Speed | Faster (simple toolpaths) | Slower (needs more adjustments) |

Cost | Lower (simpler programming) | Higher (more complex setup) |

Best For | Sheet metal, signs, flat parts | Sculptures, molds, parts with curves |

Industries | Signage, manufacturing | Automotive, aerospace, art |

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

We can turn around prototypes in as little as 48 hours. When you're on a tight deadline, our quick service can make all the difference.

Every part we make goes through rigorous quality checks. We use advanced measuring tools to make sure everything meets your specifications.

Our efficient processes mean competitive pricing, especially compared to maintaining your own CNC equipment.

Our team has years of experience with all types of CNC cutting. We can help solve design problems and suggest the best approach for your project.

Ready to start your next project? Here’s how to get the ball rolling:

Reach out with your project details

Our team will discuss your needs and suggest the best approach

We'll provide a detailed quote based on your specifications

Once approved, we'll start cutting your parts

Your finished parts will be carefully packaged and shipped to you

2D CNC cutting works with flat designs. Think of cutting out shapes from a piece of paper, but with machines that can cut metal, wood, or plastic. The machine moves on two axes (left-right and forward-backward) to make perfect cuts.

3D CNC cutting is more complex. These machines can move in three or more directions to create shapes with depth and curves. This is like sculpting instead of just cutting out shapes.

At Istar Machining, we use both types to make parts for many different industries.

CNC cutting specifically refers to the process of cutting materials, while CNC machining is a broader term that includes cutting, drilling, milling, turning, and more.

We work with most common CAD formats including DWG, DXF, STEP, and STL files.

Our standard machines handle materials up to 4′ x 8′, but we can accommodate larger projects with our specialized equipment.

Our machines can achieve tolerances as tight as ±0.005mm, depending on the material and specific requirements.

Absolutely! That’s what CNC cutting is all about. If you can design it in CAD software, we can probably cut it.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or