Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

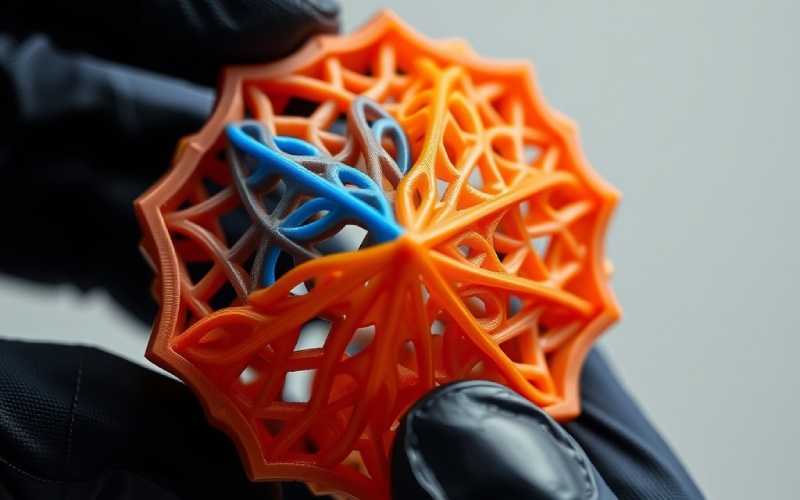

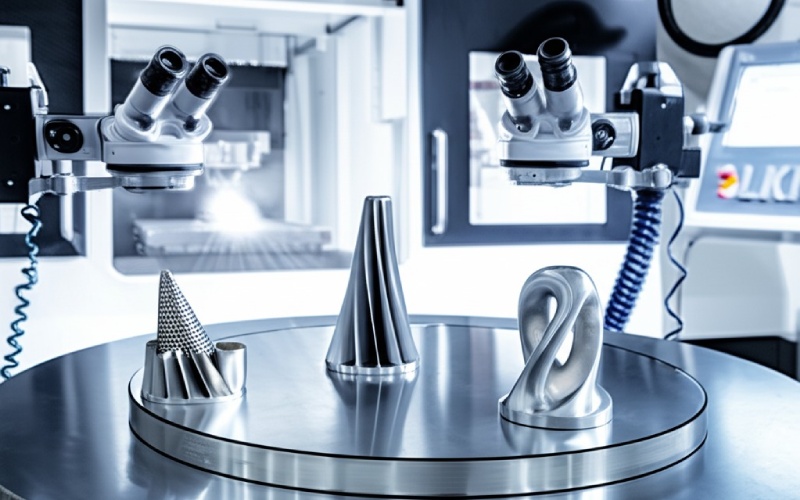

Are you looking to make complex parts with amazing detail? 3D CNC milling might be just what you need! This special type of machining lets us create almost any shape you can dream up. Let’s explore how it works and why it’s so useful.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

3D CNC milling is a cool technology that carves out parts from solid blocks of material. Unlike basic cutting, 3D milling can create curved surfaces, deep pockets, and fancy details that match your computer design exactly.

With 5-axis machining, we can reach all sides of your part in one setup. This means better quality and faster production!

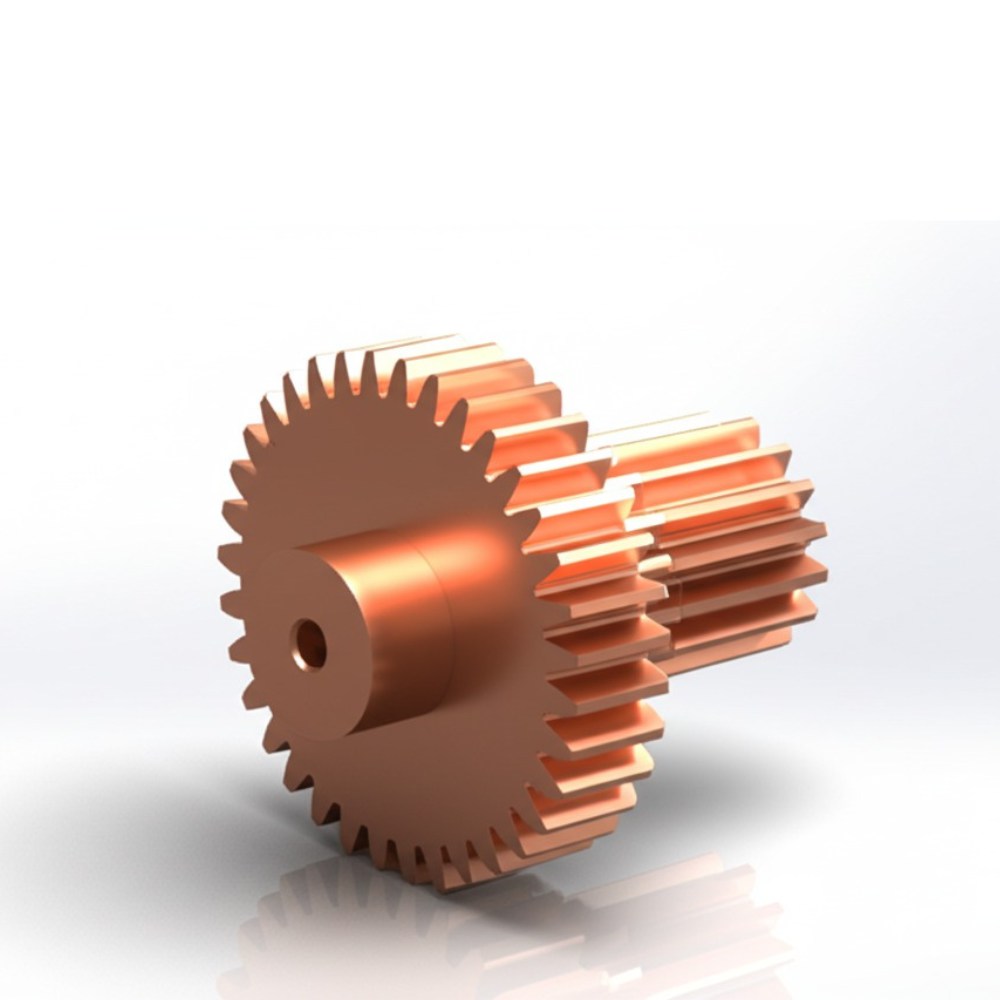

3D CNC milling machines come in different types:

For truly amazing results, 5-axis machining is the way to go. It lets us make parts in one setup that would take multiple setups on simpler machines.

Different materials are better for different jobs. Our advanced 3D CNC milling capabilities allow us to work with a wide range of materials to meet your specific project needs. Here’s a breakdown of common materials and what works best:

Metals

(Common Grades: 6061, 7075, 5052, 2024, MIC-6) Aluminum alloys are known for being lightweight, having an excellent strength-to-weight ratio, good corrosion resistance, and high thermal and electrical conductivity. They are generally very easy to machine.

Good for:

Why customers love it: “It provides an outstanding balance of strength, weight, machinability, and cost-effectiveness, making it versatile for countless prototyping and production applications.”

(Common Grades: 303, 304, 316/316L, 17-4 PH) Stainless steels offer excellent corrosion resistance, high strength, durability, and good aesthetic appeal. Machinability varies by grade (303 is easier, 316/304 are tougher).

Good for:

Why customers love it: “Its superior corrosion resistance, strength, and clean finish make it ideal for demanding environments, sterile applications, and parts requiring long-term durability.”

(Common Grades: 1018, 1045, A36) Mild steels are cost-effective ferrous alloys known for good machinability, weldability, and strength. They lack inherent corrosion resistance and typically require plating or painting for protection.

Good for:

Why customers love it: “It’s an economical and versatile material that’s easy to machine and weld, perfect for general engineering applications where high corrosion resistance isn’t needed.”

(Common Grades: 4140, 4340) Alloy steels contain additional alloying elements (like chromium, molybdenum, nickel) to enhance properties like hardness, toughness, strength, and wear resistance, often improved further through heat treatment. They are generally harder to machine than mild steels.

Good for:

Why customers love it: “Offers superior mechanical properties compared to mild steel, especially after heat treatment, enabling parts to withstand higher stresses and wear.”

(Common Grade: C360 – Free Machining Brass) Brass is an alloy of copper and zinc known for its exceptional machinability, good corrosion resistance, electrical conductivity, and attractive gold-like appearance.

Good for:

Why customers love it: “It’s arguably the easiest metal to machine, allowing for intricate details and excellent surface finishes quickly and cost-effectively. Great for high-volume turned/milled parts.”

(Common Grades: C101 (OFHC), C110 (ETP)) Copper is valued for its outstanding electrical and thermal conductivity, second only to silver. It’s also ductile and corrosion-resistant. Machinability can be ‘gummy’.

Good for:

Why customers love it: “Its unparalleled electrical and thermal conductivity makes it essential for applications requiring efficient transfer of electricity or heat.”

(Common Grades: Grade 2 (Commercially Pure), Grade 5 (Ti-6Al-4V)) Titanium boasts an exceptional strength-to-weight ratio, superb corrosion resistance (especially against saltwater and chemicals), and biocompatibility. It is challenging and expensive to machine.

Good for:

Why customers love it: “Offers an unmatched combination of light weight, high strength, and corrosion resistance, perfect for extreme performance requirements and biocompatible applications.”

(Common Alloys: AZ31, AZ91) Magnesium is the lightest structural metal, offering a very high strength-to-weight ratio and good machinability. However, fine chips are highly flammable, requiring special machining precautions.

Good for:

Why customers love it: “It’s incredibly lightweight yet strong, allowing for significant weight reduction in components where mass is a critical factor.” (Note: Machining requires specialized safety protocols).

Plastics

ABS is a common thermoplastic known for its toughness, impact resistance, rigidity, and ease of machining. It’s also relatively inexpensive.

Good for:

Why customers love it: “A cost-effective and versatile plastic offering a good balance of strength, toughness, and ease of processing for many prototyping and end-use applications.”

Delrin® (a popular brand of Acetal/POM) is an engineering thermoplastic characterized by high stiffness, low friction, excellent dimensional stability, good wear resistance, and chemical resistance. It machines beautifully to tight tolerances.

Good for:

Why customers love it: “Its excellent machinability, low friction, high strength, and dimensional stability make it ideal for precision mechanical components.”

(Common Grades: Nylon 6, Nylon 66) Nylon is known for its toughness, high wear resistance, and good chemical resistance (especially to oils and fuels). It can absorb moisture, which can affect dimensional stability and mechanical properties.

Good for:

Why customers love it: “A tough, durable, and wear-resistant plastic suitable for mechanical applications, particularly those involving friction or impact.”

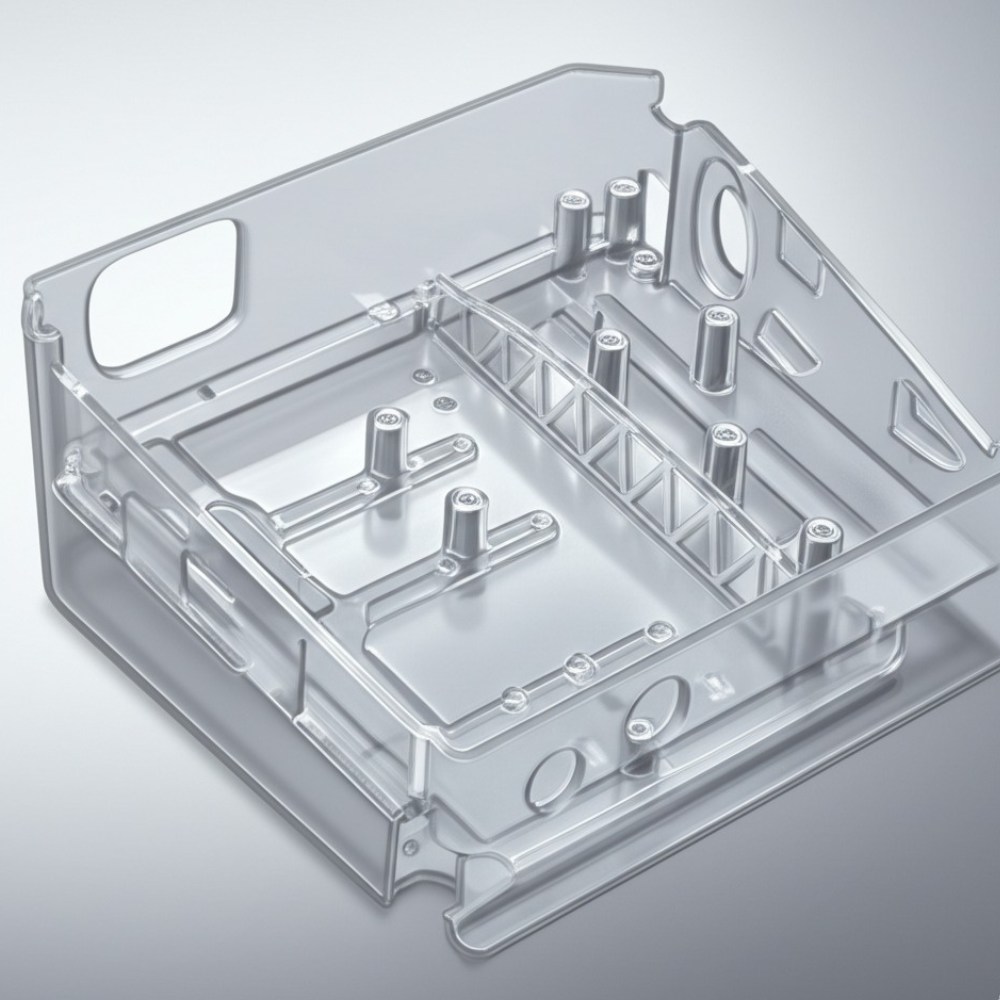

Polycarbonate is a strong, extremely tough (high impact resistance) thermoplastic that is often optically clear. It also has good heat resistance.

Good for:

Why customers love it: “Offers outstanding impact strength and toughness, available in transparent grades, making it suitable for demanding applications needing durability and visibility.”

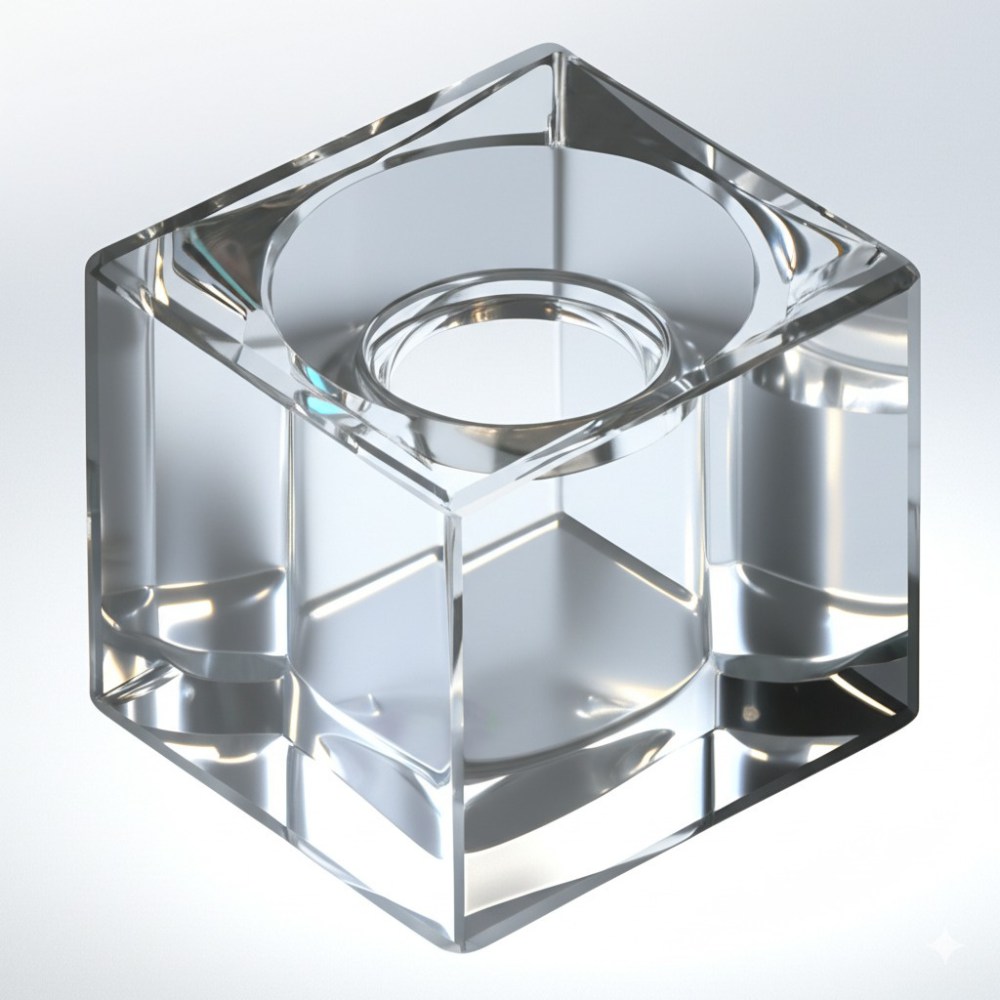

Acrylic is known for its excellent optical clarity, rigidity, weather resistance, and ease of polishing to a high gloss. It is more brittle than Polycarbonate.

Good for:

Why customers love it: “Provides exceptional clarity similar to glass but is easily machinable and polished, ideal for aesthetic and optical applications.”

PEEK is a high-performance engineering thermoplastic offering excellent mechanical strength and stiffness at high temperatures, outstanding chemical resistance, wear resistance, and inherent flame retardancy. Biocompatible grades are available. It is expensive.

Good for:

Why customers love it: “Offers top-tier performance in extreme conditions (temperature, chemical, mechanical stress), often replacing metals in challenging applications.”

UHMW PE is known for its extremely high abrasion resistance, low coefficient of friction, high impact strength, and good chemical resistance. It can be challenging to machine to very tight tolerances due to its flexibility and tendency to ‘push away’.

Good for:

Why customers love it: “Its exceptional wear resistance and low friction make it perfect for sliding applications and protecting surfaces from abrasion.”

PVC is a widely used plastic known for its excellent chemical resistance (especially acids and alkalis), good electrical insulation, and low cost. It’s rigid and relatively easy to machine.

Good for:

Why customers love it: “Offers great chemical resistance at a low cost, making it suitable for various industrial and fluid handling applications.”

Other Materials

Composites combine materials (e.g., glass or carbon fibers in an epoxy or other resin matrix) to achieve properties not possible with individual components. G-10/FR4 is a glass-epoxy laminate known for high strength, low moisture absorption, and electrical insulation. Carbon fiber composites offer exceptional stiffness-to-weight and strength-to-weight ratios. Machining composites requires specific tooling (often diamond-coated) and dust control due to abrasive dust.

Good for:

Why customers love it:

These are typically rigid, high-density polyurethane or epoxy foams designed for easy machining. They come in various densities, affecting strength and surface finish capability.

Good for:

Why customers love it: “Allows for very fast and easy machining of complex shapes, perfect for creating models, patterns, and checking designs before committing to harder materials.”

Look at this table showing some of the cool things you can make:

Industry | What You Can Make | Why It’s Great |

Turbine blades, engine parts | Super precise parts that must not fail | |

Implants, surgical tools | Custom shapes that fit the human body | |

Custom brackets, sensor housings | Strong parts that can handle tough conditions | |

Art & Design | Sculptures, models, molds | Amazing detail and smooth surfaces |

Jigs, fixtures, machine parts | Tools that make other manufacturing easier |

As a top 5 CNC machining factory in China, we offer:

For parts that fit perfectly

Get your parts quickly

Great value for amazing quality

Almost anything you can imagine

We check every part before shipping

There are many good reasons to pick 3D CNC milling for your project:

Our prototype CNC milling service has helped create:

Here are some important facts about our 3D CNC milling service:

Ready to turn your idea into reality? Here’s how to begin:

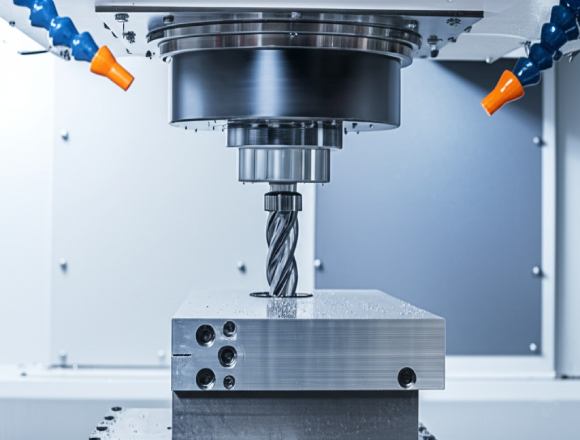

The magic of 3D CNC milling happens in these steps:

1.You send us your 3D computer model (CAD file)

We'll tell you the price and timeline within 1 hour

Our 5-axis CNC mills follow these paths to carve your part

We check everything with precise measuring tools

Your finished part is ready to use!

Whether you need aluminum CNC milling or complex CNC machining for special projects, we’re here to help. Our expert team will work with you from design to delivery.

Contact us today to learn how 3D CNC milling can bring your ideas to life!

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or