Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

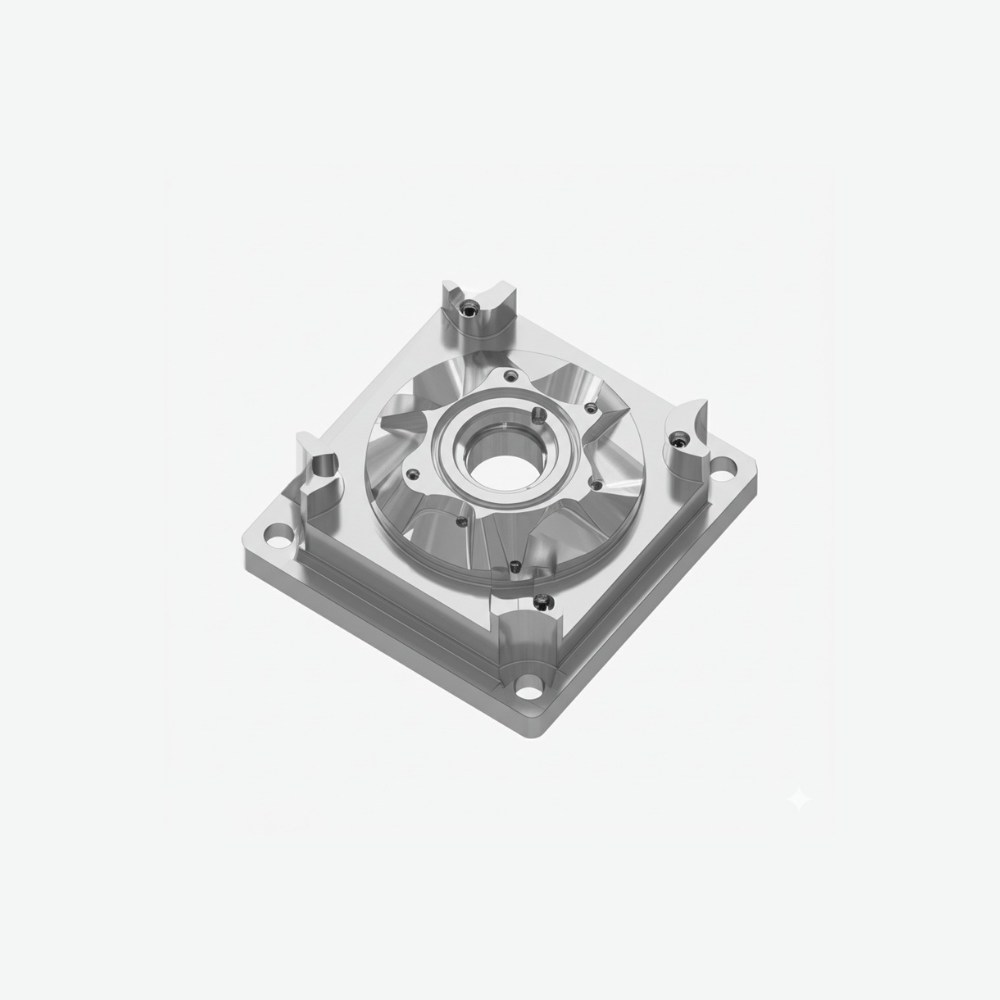

Are you looking to make complex 3D designs in wood, metal, or plastic? Our 3D CNC routing service turns your ideas into real products with amazing detail. Let’s explore how this cool technology can help you make awesome 3D creations!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

3D CNC routing is a special way to carve materials into three-dimensional shapes using computer-controlled machines. Unlike flat cutting, 3D routing can create:

Our 5-axis machining technology lets us cut materials from many angles to create even the most complex designs!

Feature | Details | Why It Matters |

Work Area Size | 48″ x 96″ (expandable up to 10′ x 5′) | Make small parts or huge signs – we can do both! |

Spindle Power | 5kW HSD spindle (24,000–30,000 RPM) | Fast, clean cuts in tough materials |

Axis Setup | 3-axis standard, optional 5-axis for complex shapes | Create undercuts and complex 3D shapes |

Materials We Cut | Wood, MDF, aluminum, brass, acrylic, foam, composites | Works with almost any material you need |

Software | Works with common 3D design files | Easy to turn your designs into finished products |

Accuracy | ±0.001″ precision | Every part fits perfectly |

Dust Collection | Built-in vacuum system | Keeps your parts clean and workspace safe |

Different materials are better for different jobs. Here’s what works best:

Plastics

Description: (Common Types: Cast, Extruded) A versatile thermoplastic known for its clarity, rigidity, and wide range of colors. Often used as a lightweight, shatter-resistant alternative to glass. Machines to a smooth, often polishable edge.

Good for:

Why Choose It: Offers excellent optical clarity, weather resistance, and color stability. It’s relatively cost-effective and provides a high-quality finish when machined correctly.

Description: (Common Brands: Lexan™, Makrolon™) An extremely durable and impact-resistant thermoplastic. Significantly stronger than acrylic but can be more challenging to machine cleanly without specialized tooling and techniques.

Good for:

Why Choose It: Unmatched impact strength and toughness, good temperature resistance, and inherent flame retardancy in certain grades make it ideal for demanding applications.

Description: (Types: Rigid, Expanded/Foam Board) A cost-effective and chemically resistant plastic. Rigid PVC is dense and strong. Expanded PVC (Foam Board) is lightweight with a matte finish, easy to machine.

Good for:

Why Choose It: Offers excellent chemical resistance (Rigid PVC), good electrical insulation, and is very cost-effective. Expanded PVC is lightweight and easy to handle for display purposes.

Description: A durable, abrasion-resistant thermoplastic with a waxy feel and excellent chemical resistance. Known for its low coefficient of friction.

Good for:

Why Choose It: Extremely durable, moisture and chemical resistant, impact resistant even at low temperatures, and relatively inexpensive.

Description: A common thermoplastic known for its toughness, rigidity, and impact resistance. Machines well and is easily fabricated.

Good for:

Why Choose It: Provides a good balance of strength, stiffness, toughness, and heat resistance at a reasonable cost. Accepts paint and glue well.

Description: (Polyoxymethylene) A high-strength, low-friction engineering thermoplastic with excellent dimensional stability and fatigue resistance. Machines beautifully to tight tolerances.

Good for:

Why Choose It: Exceptional machinability, high strength and stiffness, low friction, excellent wear resistance, and good chemical resistance make it a top choice for precision mechanical parts.

Woods & Wood Composites

Description: (Examples: Oak, Maple, Walnut, Cherry, Beech) Wood from deciduous trees. Known for their strength, durability, and attractive grain patterns. Machining properties vary by species.

Good for:

Why Choose It: Offers natural beauty, excellent strength and durability, and a premium feel. Different species provide unique aesthetics and working properties.

Description: (Examples: Pine, Cedar, Fir, Spruce) Wood from coniferous trees. Generally lighter, less dense, and less expensive than hardwoods. Easier to machine but can be prone to denting.

Good for:

Why Choose It: Cost-effective, lightweight, and generally easy to work with. Cedar offers good natural decay resistance for outdoor use.

Description: An engineered wood sheet material made from thin layers (plies) of wood veneer glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. Grades vary significantly (e.g., Baltic Birch, Marine Grade).

Good for:

Why Choose It: Offers good dimensional stability, strength, and resistance to warping compared to solid wood. Available in large sheets and various grades for different applications.

Description: An engineered wood product made from wood fibers, wax, and resin, formed into panels under high temperature and pressure. Very uniform density, smooth surface, no grain pattern.

Good for:

Why Choose It: Very cost-effective, dimensionally stable, provides an excellent smooth surface for painting, machines easily with consistent results (though produces fine dust).

Foams & Soft Metals

Description: (Often referred to by brand names like Sign•Foam®, Precision Board™) A rigid, closed-cell foam board specifically designed for dimensional signage, modeling, and tooling. Does not have grain, machines easily, and is waterproof.

Good for:

Why Choose It: Exceptionally easy and fast to machine, creates crisp details, very stable, waterproof, and accepts paint and finishes extremely well. Lighter than wood.

Description: (Expanded Polystyrene & Extruded Polystyrene) Lightweight, rigid foams commonly used for insulation. EPS has a visible bead structure; XPS is typically denser and smoother.

Good for:

Why Choose It: Very lightweight and low cost. Easy to cut quickly into large forms. XPS offers a smoother surface than EPS.

Description: (Common Grades: 6061, 5052, 7075) A lightweight, corrosion-resistant metal with excellent thermal and electrical conductivity. Very machinable with the right tools and techniques (especially grades like 6061).

Good for:

Why Choose It: Offers an excellent strength-to-weight ratio, corrosion resistance, recyclability, and a clean, modern aesthetic. Relatively easy to machine compared to harder metals.

Description: An alloy primarily of copper and zinc. Known for its decorative gold-like appearance, corrosion resistance, and good machinability.

Good for:

Why Choose It: Attractive appearance, good corrosion resistance, and relatively easy to machine, producing fine details.

Create eye-catching business signs with:

Test your product ideas with working models:

Turn your creative ideas into 3D reality:

Create perfect molds for:

Add beautiful details to buildings:

Our 3D CNC routing helps many different industries:

For complex projects, we offer advanced options:

For the most complex shapes with undercuts

Combine different materials in one project

Projects up to 10 feet long

Tiny details for model making

Make multiple identical pieces

Ready to bring your 3D designs to life? Contact Istar Machining today! As a top 5 CNC machining factory in China, we provide high-precision, high-efficiency CNC machining service for all your needs.

For projects that need both 3D routing and detailed cutting, our 2D&3D CNC cutting service offers the perfect combination!

Contact us today to discuss your 3D CNC routing project and get a free quote!

Upload your CAD files (like STEP or IGES format)

We'll tell you the price and timeline within 1 hour

Our skilled machinists program the CNC machines

Every part is inspected before shipping

Your parts arrive on time, ready to use

A: Yes! We can route aluminum, brass, and other soft metals with great results.

A: Very detailed! Our machines can create tiny details down to 0.02″ in size.

A: Simple projects can be done in 1-3 days. Complex projects may take 1-2 weeks.

A: We work with .STL, .STEP, .DXF, and most other 3D design formats.

A: It’s very cost-effective for custom projects compared to other methods.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or