Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

3D printing and CNC machining might look the same at first. Both take a computer design and turn it into a real object. But the way they work is very different. This article will explain all about 3D printing vs. CNC machining. We’ll see what they are, what’s good and bad about them, and how to pick the right one for your job. It’s important to understand them if you are making just one test part or many parts.

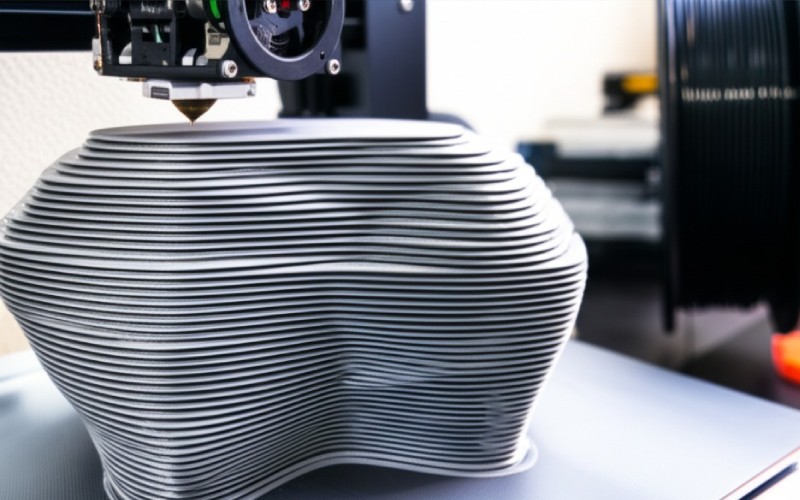

Have you ever wondered how a 3d printer can make something out of nothing? 3D printing, also known as additive manufacturing, builds things one layer at a time. Think about building with LEGO bricks, one brick after another. A 3d printer does something like that, but with materials like plastic or metal. It starts with a 3D model on a computer. The printer cuts the computer model into thin slices. Then it prints them one on top of another until the part is finished. This process is called additive manufacturing because material is added to make the part.

There are a few kinds of 3D printing technology. The most common is Fused Deposition Modeling (FDM). An FDM 3d printer works by melting a plastic string and pushing it out through a small tip, like a hot glue gun. This melted plastic is put down layer by layer to make the final thing. Another kind is Stereolithography (SLA), which uses a laser to turn liquid plastic into a solid part. There is also Selective Laser Sintering (SLS), which uses a laser to melt powder and stick it together. Each way of printing is good at different things. But they all build things layer by layer. The 3d printing process is a great tool for making tricky shapes. This makes 3d printing great for making detailed designs.

So, how is a CNC machine different from a 3D printer? A CNC machine, which is short for Computer Numerical Control, works the other way. It’s a kind of subtractive manufacturing. Instead of adding material, a CNC machine starts with a solid block of stuff, called a blank. It cuts away what isn’t needed to show the final part. Think of an artist carving a statue from a block of stone. That’s basically what a CNC machine does, but with amazing accuracy and control.

The work starts with a 3D model, just like with a 3d printer. This model is turned into instructions called G-code. The CNC machine can read these instructions. These instructions tell the cutting tools just where to move and how to cut the material. A CNC machine can use different tools like drills and cutters to make the part’s shape. This way of making things is known for being very exact. It can also work with many kinds of materials, including metals, plastics, and wood. Being so exact is a big plus for a CNC machine. CNC machining is usually more exact than 3D printing.

The biggest difference between 3D printing and a CNC machine is the way of making things. 3D printing is an additive manufacturing process. It builds objects by adding material layer by layer. This lets you make very complex and fancy shapes. These shapes would be hard or impossible to make in other ways. Because you’re only adding the material you need, there is often less waste.

On the other hand, CNC machining is a subtractive manufacturing process. It starts with a solid block of material and takes away, or subtracts, material to make the final shape. This way is great for making strong, long-lasting parts that are smooth to the touch. CNC machining cuts away stuff, which makes waste. But the parts it makes are usually very strong.

| Feature | 3D Printing (Additive) | CNC Machining (Subtractive) |

|---|---|---|

| Process | Adds material layer by layer | Cuts away material from a block |

| Waste | Less leftover material | More leftover material |

| Complexity | Great for complex shapes | Harder to make inner shapes |

| Strength | Can be weaker because of layers | Makes strong, solid parts |

So, when is 3D printing the right pick? 3D printing is perfect for making quick test models (prototypes). If you have a new idea and want to make a real model fast to check its shape and how it fits, a 3D print is usually the quickest and cheapest way. You can hold the prototype in just a few hours. This makes 3d printing a big help when making new products.

3D printing is also great for tricky designs. If your part has fancy paths inside, empty spaces, or curvy shapes, 3d printing gives you more freedom to design it. A CNC machine can find it very hard or impossible to make these things. Being able to make such complex parts is a big plus for 3D printing technology. 3D printing is usually better if you only need a few parts or one special part.

Now, let’s talk about when you should use CNC machining. If you need parts that are very exact and have to be a perfect size (tight tolerance), CNC machining is usually the better pick. A CNC machine can be more accurate than most 3D printers. This is very important for parts that must fit together just right or work under pressure.

CNC machining is also the main way to make strong and long-lasting parts, especially from metal. The parts are cut from a solid block. So, they don’t have weak spots between layers like a 3D printed part can. When you need strong metal parts, a CNC machine is the best choice. CNC machines can use more types of materials. This includes very strong metals and special plastics. CNC machining often costs less per part when you are making a lot of them.

The stuff you can make parts from is a big deal when choosing between 3D printing and CNC. Materials for 3D printing are much better now. You can now get a 3D print in different plastics like ABS and PLA. You can also print with some metals and resins. But, there are still fewer material choices for 3D printing than for CNC machining.

A CNC machine can work with a huge number of materials. This includes many metals like aluminum, steel, and titanium. It also includes plastics, wood, and other mixed materials. Being able to use so many materials is a big plus for CNC machining. If your part needs to be made of a special material, a CNC machine is more likely to be able to make it. The materials used for CNC machining are often stronger and last longer than materials for 3d printed parts.

Being exact and having the right size are very important when making things. Tolerance means how much a part’s size can be slightly off and still be okay. CNC machining is known for being very exact and having a tight tolerance. A CNC machine can make parts that are very accurate and all the same. You can get sizes that are correct within ±0.001 inches with a CNC machine.

How exact a 3D print is can change based on the kind of printer you use. Big, expensive industrial 3D printers can be very accurate. But they usually are not as exact as a CNC machine. Because 3D printing builds in layers, the surface of the part can have lines you can see. It might not be perfectly smooth. For jobs where you need a very smooth surface and a perfect size, CNC machining is usually the better choice.

People talk a lot about metal 3D printing vs. CNC machining for metal parts. Metal 3D printing is a new and fast-growing technology. It lets you make complex metal parts that a CNC machine could not make. Think of light parts with web-like patterns inside. This is a big help in fields like building airplanes and in medicine.

But, metal 3D printing is still pretty new and costs a lot. CNC machining is still the main way most metal parts are made. A CNC machine can make metal parts that are stronger, more exact, and smoother than most metal 3D printers. For most jobs that need metal parts, CNC machining is the smarter and cheaper choice. As metal 3d printing technology gets better, this could change later on.

Cost is always important to think about. If you only need one test part or just a few parts, 3D printing is often cheaper. This is because it does not cost much to get started. You just need the 3D model and the printer. The cost of a 3d print mostly depends on how much material you use.

CNC machining, however, can cost more to set up at the start. This is because you might need special tools and clamps to hold the part. But once the machine is ready, the price for each part goes down a lot if you make more of them. When making a lot of parts, CNC machining is usually cheaper than 3D printing. How complex the part is also matters. A very complex part might be cheaper to 3D print, even if you need a lot. This is because it would be very hard and take a long time to make with a CNC machine.

Picking between 3D printing and a CNC machine really depends on what your project needs. There is no single “better” option. You need to think about a few things to make the right choice. What’s the best way to make this choice? Ask yourself these questions.

First, think about what your part is for. Is it a fast test model to see how it looks and feels? Or is it a working part that needs to be strong and long-lasting? For a simple test model, a 3d print is usually the best choice. For a working part, a CNC machine might be a better fit. The choice between 3d printing and cnc machining is a very important one.