Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

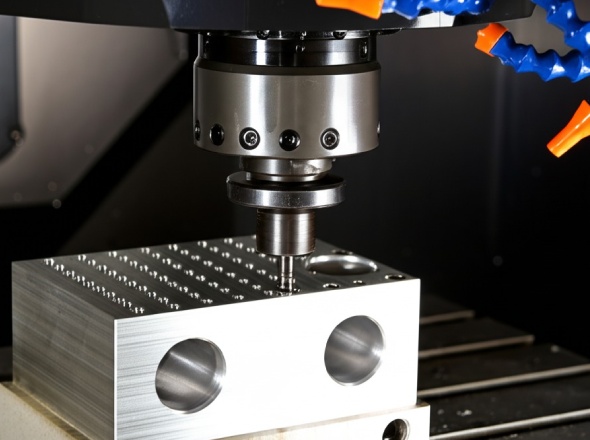

Are you looking for a way to make complex parts with perfect holes from any angle? 5-axis machining might be just what you need! At Istar Machining, we help companies make amazing parts using this special drilling method. Let’s learn all about it!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

5-axis drilling is a super smart way to make holes in parts. Regular machines can only move in 3 ways (up/down, left/right, forward/back), but 5-axis machines can also turn and tilt. This means they can drill holes at any angle without having to stop and move the part.

Think of it like this: normal drilling is like using a regular drill at home where you have to keep moving your workpiece. But 5-axis drilling is like having magic hands that can hold the drill at any angle while your part stays in one spot!

Here’s why so many companies love using 5-axis drilling:

Feature | What It Does | Why It Matters |

High-Speed Spindles | Spins up to 50,000 RPM | Makes clean, smooth holes without rough edges |

Tool Monitors | Watches drill bits for wear | Tells you when to change tools before they break |

Cooling System | Sprays coolant through the drill bit | Helps drill tough materials like titanium without overheating |

Measuring Probes | Checks parts during machining | Makes sure everything is perfect while working |

Smart Controls | Computer brain for the machine | Helps make complex shapes automatically |

5-Axis drilling is perfect for many different industries:

Use it for wing pieces, engine parts, and fuel nozzles. The precision is perfect for parts that need to be light but super strong.

Makes tiny holes (smaller than 1mm!) for things like bone implants and surgical tools. The clean finish is great for parts that go in the human body.

Perfect for engine blocks, special cooling channels, and parts for electric cars. Can drill holes at weird angles that would be impossible with regular machines.

Great for wind turbine parts and oil drilling equipment that need strong, precise holes.

Switching to 5-axis drilling can really help your company:

Our 5-axis drilling machines work with all the popular design software:

Our advanced 5-axis drilling capabilities allow us to work with a diverse range of materials, enabling the creation of complex geometries, angled holes, and intricate features with high precision. Here’s a look at the materials we commonly process:

Metals

(Common Grades: 6061, 7075, 5052, 2024) is lightweight, corrosion-resistant, has excellent thermal and electrical conductivity, and offers superb machinability, making it ideal for complex 5-axis operations.

Good for:

Why customers love it: “It provides an outstanding balance of strength, weight, machinability, and cost-effectiveness. Its ease of machining allows for rapid creation of highly complex parts using 5-axis techniques, perfect for both prototyping and production.”

(Common Grades: 304, 316, 17-4 PH) offers high strength, excellent corrosion resistance, and good heat resistance. While more challenging to machine than aluminum, 5-axis drilling enables complex features in durable parts.

Good for:

Why customers love it: “Its superior durability and resistance to corrosion and heat make it suitable for harsh environments. 5-axis drilling allows for the creation of robust parts with complex geometries that would be difficult otherwise.”

(Common Grades: 4140, 4340) provides higher strength, toughness, and wear resistance compared to mild steel. Often heat-treatable for enhanced properties. 5-axis drilling is used for creating precise features in strong components.

Good for:

Why customers love it: “Offers enhanced mechanical properties for demanding applications where strength and wear resistance are critical. 5-axis drilling enables precise features like oil passages or mounting points on complex surfaces of these tough materials.”

(Common Grades: Grade 2, Grade 5 / Ti-6Al-4V) boasts an exceptional strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. Machining is challenging but necessary for high-performance applications often requiring 5-axis capabilities.

Good for:

Why customers love it: “Unmatched performance for weight-critical, high-temperature, corrosive, or biocompatible applications. 5-axis drilling is often essential to create the necessary intricate geometries demanded by these advanced sectors.”

(Common Alloys: C360) is known for its excellent machinability, good corrosion resistance, and electrical conductivity. It’s easily formed into complex shapes using 5-axis techniques.

Good for:

Why customers love it: “Extremely easy to machine, allowing for high-speed production of complex parts with fine details and excellent surface finishes using 5-axis drilling and milling.”

(Common Alloys: C101, C110) offers outstanding electrical and thermal conductivity. It’s relatively soft and requires careful machining, but 5-axis allows for complex shapes maximizing its properties.

Good for:

Why customers love it: “Its superior conductivity is critical for many electrical and thermal applications. 5-axis machining enables the creation of complex geometries needed to optimize performance in these areas.”

(e.g., Inconel, Hastelloy, Monel) are nickel-, cobalt-, or iron-based alloys designed for extreme environments involving high temperatures, high stresses, and corrosive atmospheres. They are very difficult to machine, often necessitating advanced 5-axis techniques.

Good for:

Why customers love it: “Provides unparalleled performance in the most extreme conditions where other metals fail. 5-axis machining is often the only way to produce the highly complex parts required for these critical applications.”

Plastics & Composites

(Polyether Ether Ketone) is a high-performance engineering thermoplastic known for its excellent mechanical strength, high-temperature resistance, chemical inertness, and biocompatibility.

Good for:

Why customers love it: “Offers exceptional performance across a wide range of demanding conditions, including high temperatures and chemical exposure. 5-axis drilling allows for intricate designs suitable for medical and aerospace use.”

Delrin (Acetal/POM) is an engineering thermoplastic characterized by its high stiffness, low friction, excellent dimensional stability, and good machinability.

Good for:

Why customers love it: “Provides a great balance of stiffness, low friction, and machinability, making it ideal for precise mechanical components. 5-axis drilling easily creates complex features and tight tolerance holes.”

Nylon (PA) is a versatile engineering thermoplastic known for its toughness, wear resistance, and good chemical resistance. Various grades offer different properties (e.g., PA6, PA66, Glass-filled).

Good for:

Why customers love it: “Offers good toughness and wear resistance at a reasonable cost. 5-axis drilling allows for complex shapes and features in functional prototypes and end-use parts.”

Polycarbonate (PC) is a strong, impact-resistant thermoplastic that is naturally transparent. It maintains rigidity up to relatively high temperatures.

Good for:

Why customers love it: “Its high impact strength and transparency are key advantages. 5-axis drilling enables precise features, holes, and cutouts on complex curved or angled surfaces.”

ABS (Acrylonitrile Butadiene Styrene) is a common thermoplastic known for its toughness, impact resistance, and ease of processing. It’s often used for prototyping and general-purpose parts.

Good for:

Why customers love it: “A cost-effective and versatile material, great for prototyping complex designs using 5-axis techniques before committing to more expensive materials or tooling.”

Acrylic (PMMA) is a rigid thermoplastic known for its excellent clarity, weather resistance, and availability in various colors. It is more brittle than Polycarbonate.

Good for:

Why customers love it: “Offers exceptional optical clarity, similar to glass but lighter and easier to machine into complex shapes using 5-axis methods, although care must be taken due to its brittleness.”

Carbon Fiber Reinforced Polymer (CFRP) consists of strong carbon fibers embedded in a polymer matrix (typically epoxy). It offers an extremely high strength-to-weight ratio and stiffness but is abrasive to machine.

Good for:

Why customers love it: “Provides ultimate lightweight strength and stiffness critical for performance applications. 5-axis drilling is essential for accurately creating complex mounting holes, trimming edges, and contouring without causing delamination in this advanced material.”

Fiberglass (Glass Reinforced Polymer / GFRP) uses glass fibers in a polymer matrix. It offers good strength, durability, and corrosion resistance at a lower cost than CFRP, but is also abrasive to machine.

Good for:

Why customers love it: “A cost-effective composite solution offering good strength and environmental resistance. 5-axis drilling allows for precise shaping, trimming, and hole placement needed for assembly and integration.”

When you choose Istar Machining for your CNC prototype machining, you’re getting a complete solution. We help with:

If your project has challenging requirements, 5-axis drilling shines brightest. Unlike simple CNC drilling methods, our advanced 5-axis approach handles:

Ready to see how 5-axis drilling can transform your manufacturing? Contact Istar Machining today for a free consultation! We’ll show you how our precision machining services can save time, cut costs, and improve your final products.

Upload your CAD files (like STEP or IGES format)

We'll tell you the price and timeline within 1 hour

Our skilled machinists program the CNC machines

Every part is inspected before shipping

Your parts arrive on time, ready to use

Yes, for most metals! It’s faster and often cheaper. The only time you might want the others is for super-hard materials.

It’s more expensive at first, but most companies save about 40% on costs over three years because they finish parts so much faster with fewer mistakes.

We can make holes as small as 0.5mm (about the width of a strand of spaghetti) with excellent finish quality!

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or