Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

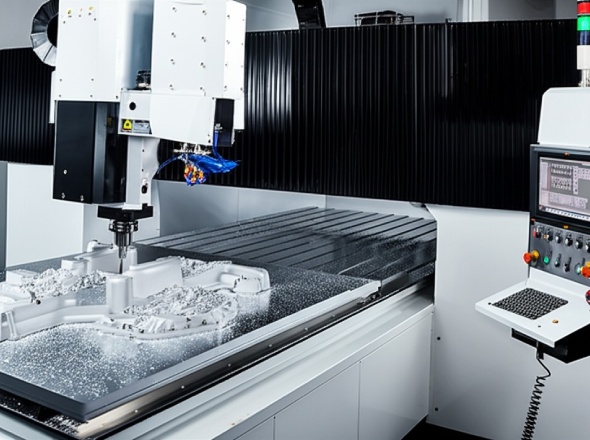

Are you looking to make complex parts with fewer setups? Do you need to cut unusual angles that regular machines can’t handle? 5-axis routing might be just what you need! This amazing technology helps make parts for airplanes, medical devices, and cool sculptures – all with amazing precision.

At Istar Machining, we’re experts in 5-axis machining that can turn your toughest designs into real parts. Let’s explore what makes 5-axis routing so special and how it can help your projects!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

5-axis routing is a super smart way to cut and shape materials. Unlike regular machines that move in just 3 directions (up-down, left-right, forward-backward), 5-axis machines can also tilt and rotate the cutting tool or the part being cut.

Think of it like this: regular machines can only cut from the top, like using a cookie cutter. But 5-axis machines can cut from almost any angle – even underneath and around corners!

The “5 axes” are:

This means the cutting tool can reach places that would be impossible with simpler machines.

With regular machines, you might need to stop, flip the part over, and set everything up again multiple times. But with 5-axis routing, the machine can reach all sides of your part without stopping. This means:

When looking at 5-axis routing systems, these are the important details:

Our advanced 5-axis CNC routing capabilities allow us to machine a diverse range of materials with high precision and complexity. Whether you need prototypes, custom parts, or production runs, we can work with the right material for your specific project needs. Here’s a look at what we commonly machine:

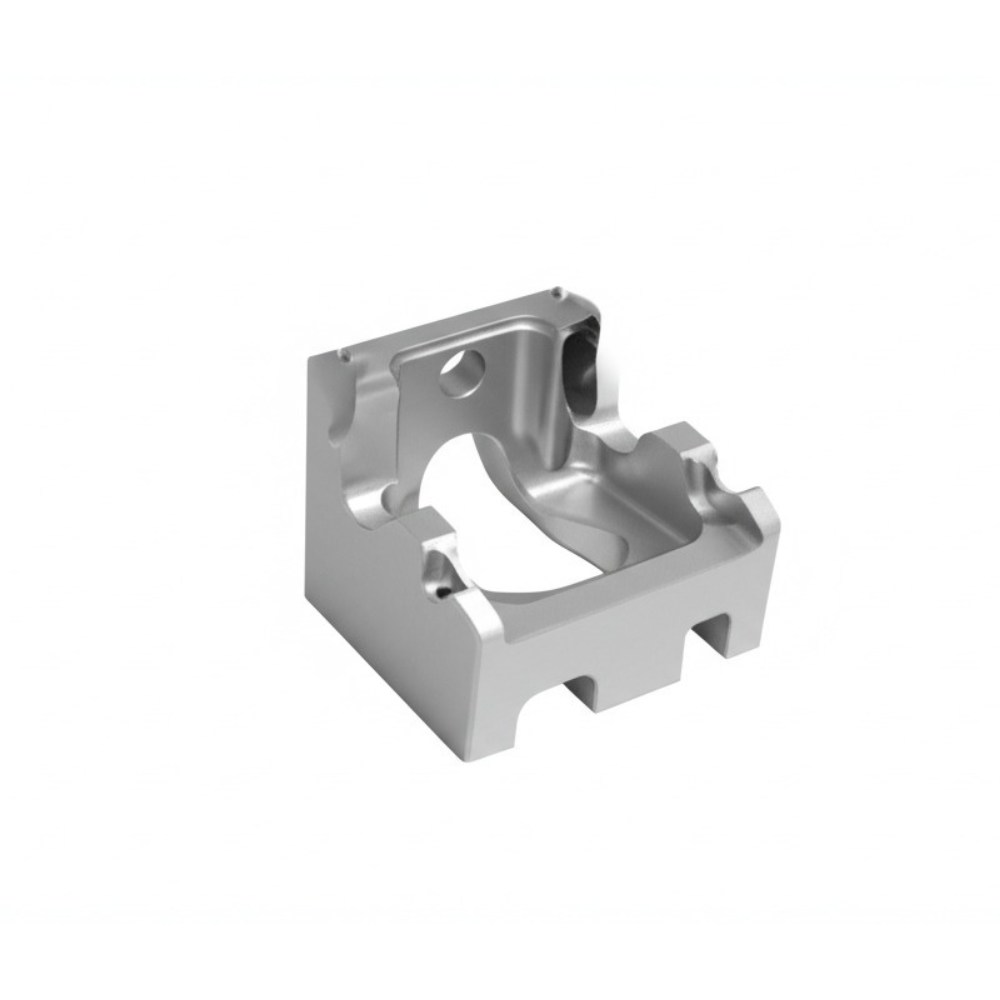

Metals

(Common Grades: 6061, 7075, 5052, 2024, MIC-6) Lightweight, corrosion-resistant, has excellent thermal and electrical conductivity, and is highly machinable, making it ideal for complex 5-axis work.

Good for:

Why customers love it: “It provides an outstanding balance of strength, weight, machinability, surface finish, and cost-effectiveness, making it incredibly versatile for countless prototyping and production applications, especially those needing intricate 5-axis features.”

(Common Grades: 303, 304, 316, 17-4 PH) Offers high strength, excellent corrosion resistance, and good heat tolerance. While harder to machine than aluminum, 5-axis routing allows for complex parts in demanding environments.

Good for:

Why customers love it: “Its superior durability, corrosion resistance, and clean aesthetic make it perfect for high-performance applications, medical-grade parts, and components exposed to harsh conditions, even with complex 5-axis designs.”

(Common Grades: 1018, 1045, A36, 4140, 4340) Provides high strength, durability, and toughness at a lower cost. Alloy steels offer enhanced properties like hardness and wear resistance. Requires coating (mild steel) to prevent rust.

Good for:

Why customers love it: “Offers excellent strength and toughness for demanding mechanical applications at a competitive price point. 5-axis machining unlocks complex geometries for robust parts.”

(Common Grades: Grade 2, Grade 5 / Ti-6Al-4V) Boasts the highest strength-to-weight ratio among common metals, exceptional corrosion resistance, and biocompatibility. It’s challenging to machine but suitable for high-value, complex 5-axis parts.

Good for:

Why customers love it: “Unbeatable strength-to-weight ratio, biocompatibility, and resistance to extreme environments make it essential for critical applications where performance and weight savings justify the cost and machining complexity.”

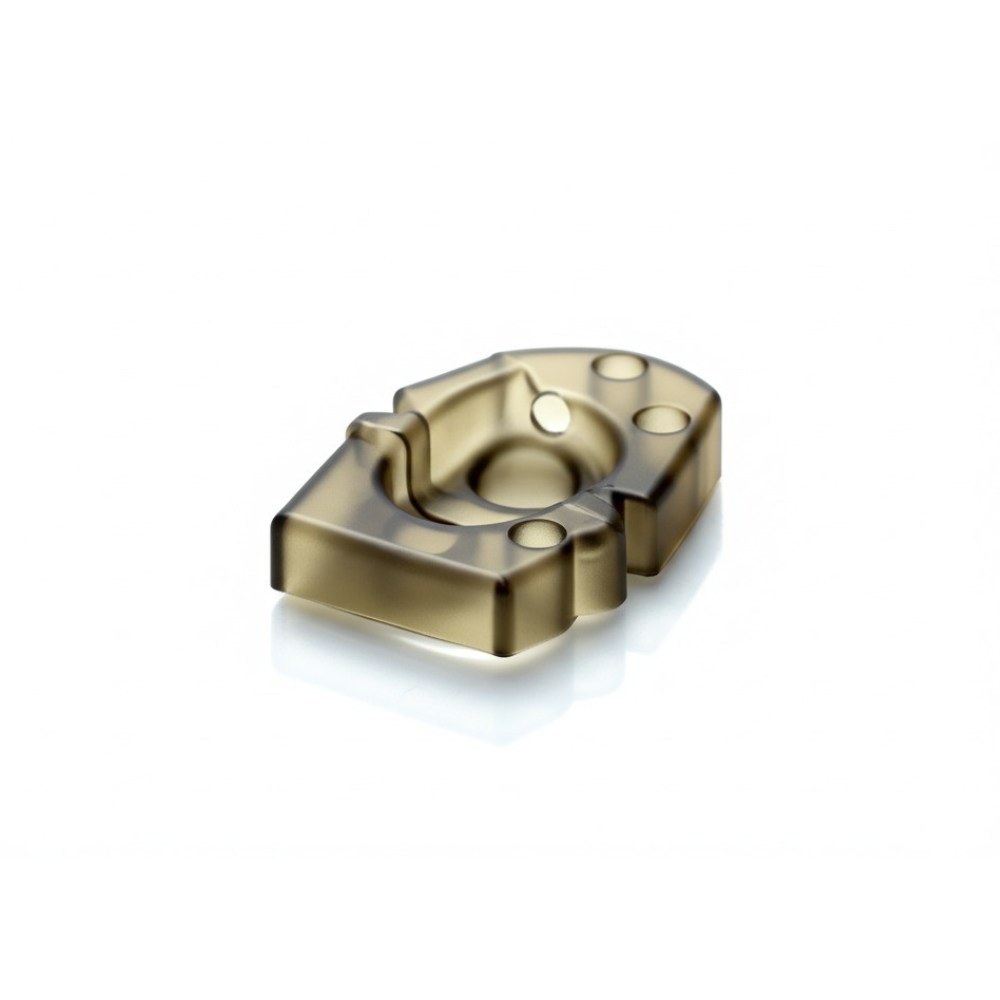

(Common Grades: C360 – Free Machining, C260 – Cartridge) Offers excellent machinability, good corrosion resistance, electrical conductivity, and an attractive golden appearance. It’s often used for intricate decorative or functional parts.

Good for:

Why customers love it: “Its superb machinability allows for fine details and excellent finishes with 5-axis routing, combined with good corrosion resistance and an aesthetic appeal, perfect for complex fittings and decorative items.”

(Common Grades: C101 – OFHC, C110 – ETP) Features outstanding electrical and thermal conductivity, good corrosion resistance, and unique reddish color. It’s relatively soft and highly ductile, requiring careful machining techniques.

Good for:

Why customers love it: “Nothing beats its thermal and electrical conductivity. 5-axis machining enables highly efficient and complex heat sinks or electrical parts where performance is paramount.”

Plastics

(Acrylonitrile Butadiene Styrene) A common thermoplastic known for its toughness, impact resistance, rigidity, and ease of machining. It’s a cost-effective choice for prototyping and functional parts.

Good for:

Why customers love it: “A versatile workhorse plastic offering a great mix of impact strength, machinability, and affordability. Ideal for quickly creating complex, functional prototypes using 5-axis routing.”

(Common Trade Names: Lexan, Makrolon) An extremely tough, impact-resistant thermoplastic with high strength and good temperature resistance. It’s naturally transparent, making it suitable for clear parts.

Good for:

Why customers love it: “Its incredible impact strength and optical clarity provide safety and visibility. 5-axis routing allows us to create complex guards and transparent parts that can withstand tough environments.”

(Common Trade Names: Plexiglas, Lucite) Offers excellent optical clarity, weather resistance, and rigidity. It machines well to a smooth, often polishable finish and comes in various colors. More brittle than PC.

Good for:

Why customers love it: “Delivers crystal-clear results and beautiful finishes. Perfect for aesthetic parts, displays, and optical components where clarity is key, allowing for complex 5-axis shapes.”

(Common Grades: PA6, PA6/6, Cast, Glass-Filled) Known for its toughness, excellent wear resistance, low friction coefficient, and good chemical resistance (especially to oils and fuels). Can absorb moisture, affecting dimensions.

Good for:

Why customers love it: “Its durability and low friction make it ideal for moving parts and high-wear applications. 5-axis routing allows complex gear profiles or custom wear components.”

A high-stiffness, low-friction engineering thermoplastic with excellent dimensional stability, fatigue resistance, and machinability. Often chosen for precise functional parts.

Good for:

Why customers love it: “Machines beautifully to tight tolerances, offering stiffness and low friction. Perfect for precise, durable mechanical parts easily realized with complex 5-axis features.”

(Polyether Ether Ketone) A high-performance thermoplastic offering exceptional mechanical strength, stiffness, high-temperature performance, chemical inertness, and wear resistance. Biocompatible grades are available.

Good for:

Why customers love it: “The ultimate plastic for extreme environments – high temp, harsh chemicals, high loads. 5-axis machining enables complex, critical components where other materials would fail.”

(High-Density Polyethylene / Ultra-High Molecular Weight Polyethylene) These materials offer excellent chemical resistance, low moisture absorption, and good impact strength. UHMWPE adds exceptional abrasion resistance and very low friction.

Good for:

Why customers love it: “Provides outstanding chemical resistance (HDPE) or incredible wear resistance (UHMWPE) at a good value. Ideal for liners, guides, and containers, including complex shapes made possible by 5-axis routing.”

Composites & Wood & Foams

(Carbon Fiber Reinforced Polymer) Composites offer exceptional stiffness-to-weight and strength-to-weight ratios. 5-axis routing is typically used for trimming, drilling, and machining features into pre-cured sheets or molded parts. Requires specialized tooling.

Good for:

Why customers love it: “The ultimate in lightweight strength and stiffness. 5-axis machining allows precise finishing and feature creation on complex, high-performance composite parts.”

(Glass Fiber Reinforced Polymer) (Common Grades: G10, FR4) Offers a good balance of strength, stiffness, corrosion resistance, and electrical insulation properties at a lower cost than carbon fiber. Abrasive to machine.

Good for:

Why customers love it: “A cost-effective composite providing good strength, excellent electrical insulation, and corrosion resistance. 5-axis machining handles complex shapes for structural or insulating parts.”

(Often Epoxy or Polyurethane based) Provides higher density, temperature resistance, and durability compared to standard foams, while still machining relatively easily. Offers excellent dimensional stability.

Good for:

Why customers love it: “Offers greater durability and temperature resistance than foams, ideal for creating robust master patterns, check fixtures, or short-run molds with complex 5-axis surfaces.”

(Examples: Oak, Maple, Walnut, Cherry, Teak) Offer natural beauty, good strength, and durability. Machinability varies, but generally good with sharp tools. Different species provide unique aesthetics and properties.

Good for:

Why customers love it: “Combines timeless aesthetics with strength. 5-axis routing unlocks intricate designs, complex joinery, and beautiful curves for furniture, architecture, and art.”

(Examples: Pine, Cedar, Fir, Spruce) Generally lighter, less expensive, and easier to machine than hardwoods, but also less durable and prone to denting. Good for painting or rustic finishes.

Good for:

Why customers love it: “Economical and easy to machine for large forms or prototypes. Great for quickly realizing designs or creating patterns where high strength isn’t needed, easily shaped with 5-axis.”

(Medium-Density Fiberboard) Plywood offers good strength and stability due to its layered structure. MDF provides a uniform, smooth surface ideal for painting, but is heavier and less moisture resistant.

Good for:

Why customers love it: “Engineered sheets provide predictable stability (Plywood) or a perfect paint surface (MDF) cost-effectively. Ideal for complex 2.5D and 3D shapes via 5-axis routing for jigs, patterns, and panels.”

(Tooling Foam/Board) Specifically designed for machining. It’s grain-free, dimensionally stable, and machines quickly to a fine finish. Available in various densities for different needs.

Good for:

Why customers love it: “Incredibly fast to machine complex 3D shapes with excellent detail and surface finish. Perfect for creating accurate models, patterns, and molds efficiently using 5-axis routing.”

(Expanded / Extruded Polystyrene) Very lightweight, low-cost insulation foams. Easy to cut but low strength. Often used for large-scale forms where weight and cost are primary concerns.

Good for:

Why customers love it: “Extremely lightweight and inexpensive for creating massive shapes. 5-axis routing is essential for sculpting complex curves and details on large-scale models and props.”

(Often lower density Polyurethane or similar) Typically softer and easier to shape than HDU foam, intended for quick concept visualization and basic form studies.

Good for:

Why customers love it: “Very easy and fast to machine for quick visualization. Ideal for early-stage design exploration and creating basic forms rapidly with 5-axis routing at low cost.”

Some industries really need what 5-axis routing offers:

When making airplane parts, every gram matters. 5-axis routing can make lightweight parts with perfect strength.

For things like replacement joints, the shapes need to be super smooth and match the human body. 5-axis machines can create these organic shapes.

Car makers use 5-axis routing to make prototype parts and molds for testing new designs.

Artists and designers love 5-axis routing for making sculptures, furniture, and architectural details that would be impossible to create by hand.

Here’s how 5-axis routing is used in the real world:

In the aerospace industry, parts need to be lightweight but strong. Aerospace CNC machining with 5-axis routing creates turbine blades with complex curves that would be almost impossible to make any other way.

One turbine blade might have:

With 5-axis routing, we can make these parts in a single setup with perfect accuracy.

Medical devices need special shapes that work with the human body. Using 5-axis routing, we can create:

The ability to machine at odd angles helps create these life-changing devices.

Furniture makers and artists use 3D CNC routing with 5 axes to create amazing pieces that would take months by hand:

The magic of 5-axis routing comes from its smart control systems:

Special computer programs figure out how to move the tool along complex paths

High-speed computers that coordinate all 5 axes moving at once

Sensors that constantly check the position of every part of the machine

Software that turns design files into machine movement instructions

The technology keeps getting better! New developments include:

At Istar Machining, we specialize in providing high-precision CNC milling and 5-axis routing services. Our team understands the special needs of industries that demand perfect parts, and we’re ready to help with your most challenging projects.

Want to learn more about how 5-axis routing can help your business? Contact us today for a free consultation and quote!

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or