Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

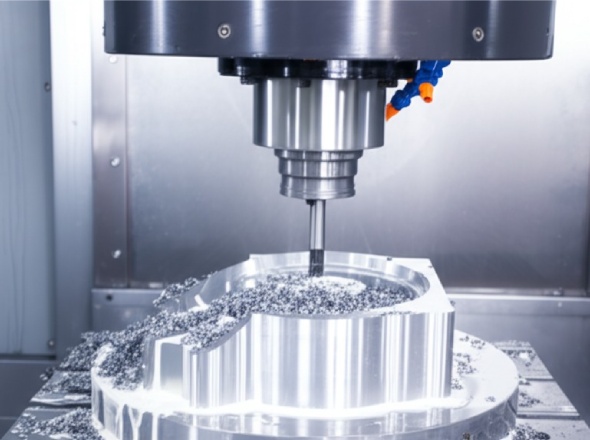

At Istar Machining, we’re proud to offer top-quality 5-axis CNC machining services that can bring your most complex designs to life. This guide will help you understand what 5-axis machining is, how it works, and why it might be the perfect solution for your next project.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Our 5-axis CNC machines use advanced computer software to control cutting tools with amazing precision. The machine follows a detailed set of instructions that tell it exactly where to cut, how deep, and at what angle.

The Five Axes Explained:

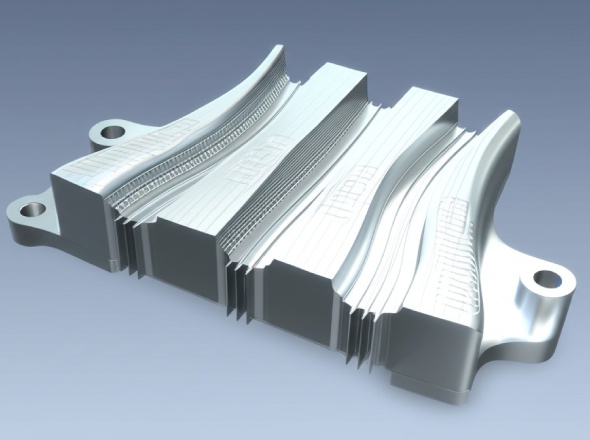

This setup allows our team at Istar Machining to create parts with complex shapes that would be impossible with simpler machines. We use special CAM software that plans the perfect cutting path to make your part quickly and precisely.

5-axis machining offers amazing advantages over older methods:

As one customer told us: “Istar Machining’s 5-axis capabilities cut our production time in half and improved part quality beyond what we thought possible.”

At Istar Machining, our 5-axis systems handle almost any material:

Metals

6061 (T6, T651): A highly versatile alloy known for its excellent machinability, good strength-to-weight ratio, weldability, and corrosion resistance. Common Finishes: Anodizing (Type II & III Hardcoat), Chromate Conversion Coating (Chem Film), Bead Blasting, Polishing, Painting, Powder Coating, As-Machined.

7075 (T6, T651): Offers very high strength and good fatigue resistance, often chosen for aerospace and high-stress applications, though harder to weld. Common Finishes: Anodizing, Chem Film, Painting, As-Machined (often used for structural strength).

2024 (T3, T351): Valued for its high strength and good fatigue resistance, commonly found in aircraft structures; exhibits fair corrosion resistance. Common Finishes: Anodizing, Chem Film, Painting, As-Machined.

5052: Features excellent corrosion resistance, especially in marine environments, combined with good formability and moderate strength. Common Finishes: Anodizing, Chem Film, Polishing, As-Machined.

MIC-6 / ATP-5: This cast tooling plate provides excellent dimensional stability, flatness, and good machinability. Common Finishes: As-Machined, Anodizing (primarily cosmetic).

Carbon Steels (e.g., 1018, 1045): Economical and versatile materials offering good strength; they are magnetic and machinability varies by grade. Common Finishes: Black Oxide, Zinc Plating, Nickel Plating, Chrome Plating, Painting, Powder Coating, As-Machined.

Alloy Steels (e.g., 4130, 4140, 4340): Generally stronger, tougher, and more wear-resistant than carbon steels, often heat-treatable for enhanced properties. Common Finishes: Black Oxide, Plating (Zinc, Nickel, Chrome), Nitriding, Painting, Powder Coating, As-Machined.

Tool Steels (e.g., A2, D2, O1, S7, H13): Selected for their high hardness, wear resistance, toughness, and heat resistance (grade-dependent), primarily used for functional tooling. Common Finishes: Often used As-Machined or Heat Treated; Polishing, Surface Grinding. Coatings (TiN, TiCN) for enhanced wear resistance.

Free-Machining Steels (e.g., 12L14): Engineered with additives for excellent machinability, enabling high-speed production. Common Finishes: Plating, Black Oxide, As-Machined.

303: An austenitic grade modified with sulfur for significantly improved machinability while retaining good corrosion resistance. Common Finishes: Passivation, Electropolishing, Bead Blasting, As-Machined.

304 / 304L: The most widely used stainless steel, providing excellent corrosion resistance, good formability, and is non-magnetic (austenitic). The ‘L’ grade offers better weldability. Common Finishes: Passivation, Electropolishing, Bead Blasting, Brushed Finish, Polishing, As-Machined.

316 / 316L: Offers superior corrosion resistance compared to 304, especially against chlorides, making it ideal for marine, medical, and chemical applications. Non-magnetic (austenitic), ‘L’ grade for improved weldability. Common Finishes: Passivation, Electropolishing, Bead Blasting, Polishing, As-Machined.

17-4 PH (Hardened Conditions): A precipitation-hardening martensitic steel delivering high strength and hardness combined with good corrosion resistance. It is magnetic. Common Finishes: Passivation, Age Hardening (Heat Treatment), As-Machined.

Martensitic Grades (e.g., 410, 416, 420, 440C): These grades are magnetic and can be heat-treated to achieve high hardness and wear resistance, offering moderate corrosion resistance. 416 is the free-machining variant. Common Finishes: Passivation, Heat Treatment (Hardening/Tempering), Polishing, As-Machined.

Grade 2 (Commercially Pure): Biocompatible with excellent corrosion resistance, moderate strength, and good weldability. Common Finishes: Passivation, Anodizing (Type II – Color), Bead Blasting, As-Machined.

Grade 5 (Ti-6Al-4V): The workhorse titanium alloy, featuring a high strength-to-weight ratio, excellent corrosion resistance, biocompatibility, and is heat-treatable. Essential for many aerospace and medical components. Common Finishes: Passivation, Anodizing (Type II – Color, Type III – Hardcoat-like), Bead Blasting, Polishing, Heat Treatment, As-Machined.

Copper (C101 OFHC, C110 ETP): Sought after for outstanding electrical and thermal conductivity, good corrosion resistance, and ductility. Common Finishes: Polishing, Plating (Nickel, Tin), Passivation (less common), As-Machined.

Brass (C360 Free-Cutting): Renowned for its excellent machinability, good corrosion resistance, and appealing aesthetic finish. Common Finishes: Polishing, Brushing, Plating (Nickel, Chrome), Lacquering, As-Machined.

Bronze (C932 Bearing, C954 Aluminum): Offers good wear resistance, strength, and corrosion resistance, making it suitable for bearing and structural applications. Common Finishes: Often used As-Machined for bearing properties; Polishing.

These materials provide exceptional performance in extreme environments involving high temperatures, high stress, and severe corrosion, though they present machining challenges. Common Finishes: Passivation, Heat Treatment, specialized coatings, As-Machined (often critical dimensions).

Plastics & Polymers

A widely used thermoplastic known for its good balance of toughness, impact resistance, and rigidity. ABS is easily machined and readily accepts paint or glue, making it a popular choice for housings, enclosures, functional prototypes, and consumer products.

Common Finishes: As-Machined (often smooth), Polishing, Painting, Vapor Smoothing, Plating (requires specialized process).

Nylon offers good mechanical strength, excellent wear resistance, toughness, and good resistance to oils and fuels. It’s frequently used for gears, bearings, bushings, and structural components. Note that Nylon tends to absorb moisture, which can affect dimensional stability. Glass-filled variants provide increased stiffness and strength.

Common Finishes: As-Machined, Dyeing, Painting.

Valued for its exceptionally high impact strength (often used for “bulletproof” applications), good temperature resistance, and inherent transparency (clear grades available). PC is suitable for protective guards, lenses, sight glasses, manifolds, and durable housings.

Common Finishes: As-Machined (can show tool marks), Polishing (for optical clarity), Vapor Smoothing, Painting.

Acrylic boasts excellent optical clarity, rigidity, and good weather resistance, often chosen for displays, light pipes, windows, and aesthetic components. It is more brittle than Polycarbonate. Machining requires sharp tooling for a clean finish.

Common Finishes: As-Machined, Polishing (flame or mechanical buffing), Gluing.

This engineering thermoplastic provides high stiffness, excellent dimensional stability, low friction (‘slippery’), and good chemical resistance. Acetal machines beautifully to a precise, smooth finish, making it ideal for gears, bearings, bushings, jigs, fixtures, and other precision mechanical parts.

Common Finishes: As-Machined (typically excellent finish), Polishing.

Renowned for its extremely low coefficient of friction (‘non-stick’), outstanding chemical inertness across a wide range of substances, and a broad operating temperature range. PTFE is relatively soft and can be challenging to machine to very tight tolerances. Used extensively for seals, gaskets, insulators, valve components, and low-friction applications.

Common Finishes: As-Machined.

A high-performance thermoplastic excelling in demanding environments due to its excellent mechanical strength (retained at high temperatures), superior chemical resistance, low outgassing, and inherent wear resistance. Medical grades are available and widely used for implants. Also common in aerospace, semiconductor, and oil & gas applications.

Common Finishes: As-Machined (can achieve good finish), Polishing.

Another high-performance plastic offering high strength and rigidity at elevated temperatures, good chemical resistance, dimensional stability, and dielectric strength. It is often amber and transparent. Frequently used for electrical connectors, medical trays (due to sterilization resistance), and aerospace components.

Common Finishes: As-Machined, Polishing.

Beyond the highlighted materials, our 5-axis machining capabilities extend to various other engineering and high-performance plastics, including:

HDPE (High-Density Polyethylene): Economical, chemical resistant, low friction. Used for containers, cutting surfaces.

UHMWPE (Ultra-High Molecular Weight Polyethylene): Extreme abrasion resistance, high impact strength. Used for wear strips, guides.

PP (Polypropylene): Lightweight, excellent chemical resistance, fatigue resistant (living hinges). Used for tanks, lab equipment.

PVC (Polyvinyl Chloride): Rigid, good chemical/corrosion resistance, electrical insulator. Used for pipes, fittings, housings.

Torlon® (PAI): Exceptional strength and wear resistance at very high temperatures. Used for demanding seals and bearings.

Radel® (PPSU): High heat resistance, withstands repeated sterilization. Common in medical devices.

PPS (Polyphenylene Sulfide): High temperature and chemical resistance, dimensionally stable. Used for pumps, electrical parts.

Vespel® (PI): Operates at extreme temperature ranges, low wear, no melting point. Used in aerospace, semiconductor.

Finishing options for these materials vary. Please inquire about specific grades and finishes.

Other Materials

Carbon Fiber Reinforced Polymers (CFRP): Delivers an extremely high stiffness and strength-to-weight ratio with anisotropic properties (directionally dependent). Common Finishes: As-Machined (texture depends on weave/layup), Clear Coating, Painting, Edge Sealing.

Fiberglass Reinforced Polymers (GFRP / G10 / FR4): Provides good strength, excellent electrical insulation properties, and good dimensional stability. Commonly used for electronic boards and structures. Common Finishes: As-Machined, Painting, Coating.

Machinable Composite Tooling Board: A stable material that is easily machined, available in various densities and temperature ratings for creating molds, patterns, and fixtures. Common Finishes: As-Machined, Sealing, Painting.

Very easy and fast to machine, ideal for rapid prototyping and casting patterns as it melts out cleanly and captures fine detail. Common Finishes: As-Machined (very smooth).

Lightweight and easily shaped materials available in various densities, used for models and prototypes. Common Finishes: As-Machined, Sealing, Painting.

Used for EDM electrodes and high-temperature applications due to its heat resistance and electrical conductivity. It is brittle and requires dust control during machining. Common Finishes: As-Machined.

Our 5-axis machining services help many different industries:

We make turbine blades and lightweight parts that must meet strict safety standards. Our 5-axis systems can handle tough materials like titanium and Inconel while maintaining perfect precision.

For medical implants and surgical tools, we achieve the mirror-smooth finishes and bio-friendly surfaces doctors demand. Our 5-axis machines work with PEEK, titanium, and other materials approved for medical use.

From custom engine parts to complex molds, our 5-axis technology helps car makers build better, lighter vehicles.

We create precision components for turbines and other power generation equipment that must withstand extreme conditions for years.

Not sure which type of machining is right for your project? This table shows the key differences:

Feature | 3-Axis | 4-Axis | 5-Axis |

Complexity | Simple flat shapes | Cylindrical parts | Complex 3D shapes |

Setup Time | Multiple setups needed | Fewer setups | Single setup for most parts |

Precision | Good for basic parts | Better | Best (±0.001″) |

Cost | Lower machine cost | Medium | Higher machine cost but better results |

Best For | Simple parts | Rotational parts | Complex, precision parts |

At Istar Machining, we’ll help you choose the right approach for your specific needs and budget.

5-axis machining is perfect when you need:

If your part has simple flat surfaces only, 3-axis might be enough. But for anything with complex geometry, 5-axis usually saves time and improves quality.

Istar Machining stands out from other shops because:

Our machinists have 10+ years of 5-axis experience

We've invested in the latest machine technology

Our quality control uses state-of-the-art measuring equipment

We've successfully completed projects for aerospace, medical, automotive, and energy customers

We offer fast turnaround even for complex parts

Ready to take advantage of Istar Machining’s 5-axis capabilities? Here’s how to get started:

Send us your CAD files or drawings

Our team will review your design for 5-axis optimization

We'll provide a detailed quote with timeline and specifications

Once approved, we'll machine your parts with precision

You'll receive perfect parts, on time, every time

5-axis CNC machining is a special type of computer-controlled cutting that moves in five different ways at once. Unlike basic machines that only move up/down, left/right, and forward/backward (X, Y, Z), our 5-axis machines add two more turning movements. This means we can cut your parts from almost any angle without stopping to flip or move them.

Think of it like this – if 3-axis machining is like drawing with a pencil on paper, 5-axis machining is like painting a 3D sculpture from all sides at once!

A: While the hourly rate is higher, total cost is often lower for complex parts because of faster production and fewer errors.

A: Our largest 5-axis machine handles parts up to 48″ x 24″ x 18″, but we can accommodate larger projects by special arrangement.

A: We regularly achieve tolerances of ±0.001″ and can achieve even tighter tolerances for special applications.

A: Almost any machinable material works well, including aluminum, titanium, steel, plastics, and composites.

A: For urgent projects, we offer rush service with delivery in as little as 3-5 days depending on complexity.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or