Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

If you strip away marketing and catalog copy, 6061-T6 is simply the grade you choose when you want aluminum that behaves predictably, machines without drama, welds acceptably, and survives outdoors long enough that nobody complains. Strong enough, corrosion-resistant enough, affordable enough. Its real value is not that it excels at one thing, but that it rarely surprises you if you respect its limits, especially at welds and in chloride-rich environments.

Look at common reference sites and you see the same sentence fragments repeated: medium-to-high strength, good weldability, good corrosion resistance, highly extrudable, general purpose.

In practice that translates to this: when a designer wants aluminum and does not have a strong reason to specify anything else, 6061-T6 quietly fills the blank. This is helped by the way mills and stockists run their businesses. Long extrusions, thick plate, bar in awkward dimensions, random shapes for CNC work—6061 is almost always on the shelf, often cheaper per kilogram than “stronger” alloys once you account for lead times, scrap, and minimum order quantities.

That availability bias shapes a lot of engineering decisions more than the stress calculations do. People rarely admit that, but supply chain usually wins arguments.

Officially, 6061 is an Al-Mg-Si alloy. Magnesium and silicon sit in the 0.8–1.2% and 0.4–0.8% windows, with copper about 0.15–0.4% and chromium 0.04–0.35%, the rest mostly aluminum and trace impurities.

You already know the story: solution heat treatment, water quench, artificial aging; Mg₂Si precipitates grow to sizes and spacings that give you the T6 strength plateau. A typical route is heating around 900 °F, quenching, then aging for several hours to build a fine hardening structure.

The important thing for day-to-day engineering is not the microstructural jargon but what that temper does to behavior: you get yield in the 240–280 MPa range, tensile strength around 290–310 MPa, elongation roughly 10–14%, and a modulus that stubbornly sits near 69–70 GPa like almost every other aluminum.

So T6 is not just “harder 6061.” It is 6061 with a particular compromise between strength, ductility, machinability, and residual stress.

Datasheets for 6061-T6 tend to quote very clean values: ultimate tensile strength around 310 MPa, yield strength near 270 MPa, elongation about 10–12%.

In reality, three things quietly distort those neat rows: thickness, direction, and history.

Thickness first. For sheet, elongation in T6 gradually falls from around 10% at sub-inch thickness toward 6% or so in thick plate; strengths remain roughly constant, but formability changes enough that you feel it at the press brake.

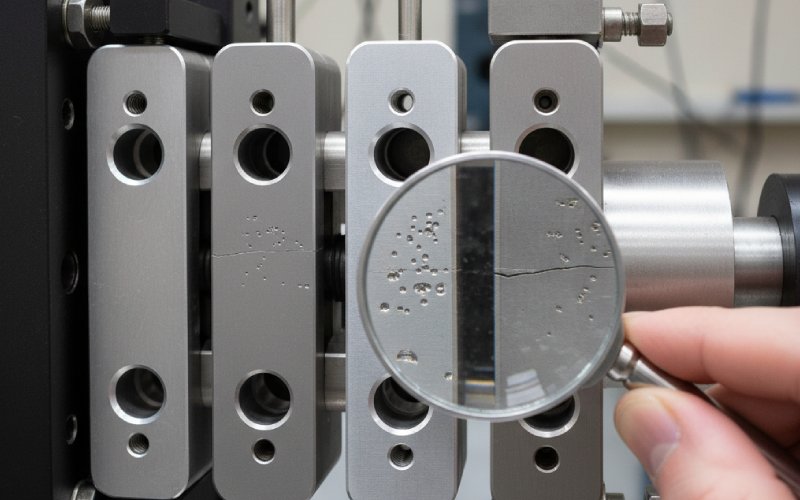

Direction next. Extrusions carry a preferred grain flow. Machine across the grain and toughness and fatigue behavior can shift, even though the quasi-static tensile numbers in the brochure look symmetrical. That does not show up in the one-line summary but it shows up in cracked brackets aligned the wrong way.

History last. Any local heating, abusive forming, or unknown prior machining can modify the local temper. A welded corner, a thick-to-thin transition that cooled unevenly, or a surface aggressively polished after heat treatment may not be behaving as neat, uniform T6 anymore. The alloy name stays the same on the print; the local properties do not.

Almost every design review that touches 6061 will hear the question: “Why not 7075?” Mechanical data gives most of the answer. 7075-T6 has roughly double the tensile strength and far higher yield, at similar modulus and density.

But that is only half the story, so it helps to see the contrast in one place:

| Property (typical) | 6061-T6 Aluminum | 7075-T6 Aluminum | Design comment |

|---|---|---|---|

| Density | ~2.70 g/cm³ | ~2.81 g/cm³ | Weight difference is modest; geometry usually dominates. |

| Ultimate tensile strength | ~290–310 MPa | ~510–560 MPa | 7075 can nearly halve required section for pure strength. |

| Yield strength | ~240–280 MPa | ~430–503 MPa | Real advantage is here: much smaller elastic-to-plastic window. |

| Elongation at break | ~8–12% (geometry-dependent) | ~5–11% | Both are ductile enough for many structures, but not forgiving like 5xxx. |

| Brinell hardness | ~95–107 HB (via Vickers/Rockwell conversions) | ~150 HB | 7075 is noticeably harder to machine, and to deform. |

| Modulus (E) | ~69–70 GPa | ~70 GPa | Stiffness per unit geometry is basically the same. |

| Corrosion resistance | Good in atmospheric and mild marine; sensitive to chlorides at defects. | Lower in many environments; more prone to stress-corrosion cracking. | 6061 is friendlier for unsheltered outdoor use. |

| Weldability (common arc processes) | Generally good; HAZ softening is the main issue. | Poor with 7xxx in T6 if strength retention is needed. | 6061 lets you join parts without exotic procedures. |

Once you lay this out, the pattern is simple: 7075-T6 is the choice when static strength dominates and welding is either avoided or highly controlled; 6061-T6 is the choice when you need to weld often, accept outdoor exposure, and keep costs and supply sane.

Most “6061-T6 is weldable” statements are technically correct but incomplete. Yes, gas metal arc and TIG processes join it well. Yes, porosity and cracking are manageable with standard practice. The catch is strength and corrosion in the heat-affected zone.

Experimental work on 6061 welds shows the obvious but often ignored result: you lose a big slice of T6 strength around the weld because the local temper is overaged or effectively closer to T4 after the thermal cycle. Mechanical testing of welded 6061 in different heat treatments highlights this shift; the base material may sit near 270–300 MPa yield, while weld metal and adjacent regions drop significantly.

Now add corrosive environments. In chloride solutions, 6061-T6 already shows localized pitting that acts as a perfect starting point for fatigue cracks; studies in NaCl-saturated conditions reported pitting in the 0.5–3.5 wt% range without huge changes in macroscopic corrosion rate, but with clear links between pits and crack initiation. Welds give you new microstructural heterogeneity and residual stresses, so the path from pit to crack simply gets shorter.

This is why a welded 6061 structure in a salty environment behaves like a different alloy system than a machined billet bracket on a lab bench, even if they share a specification line on the drawing.

Aluminum does not have the tidy endurance limit that steels pretend to have, and 6061-T6 is no exception. Long-life S-N curves keep drifting downward; textbook numbers often quote around 14 ksi (about 97 MPa) for 500 million fully reversed cycles in air for 6061-T6, but this is a conventional definition, not a real “infinite life” boundary.

Add chloride, and things move quickly. Multiple studies report order-of-magnitude reductions in fatigue life when 6061-T6 specimens are cycled in NaCl solution compared with laboratory air. The failure pattern is consistent: pitting at intermetallic particles (especially Fe-rich phases) provides a high-stress micro-notch; cracks grow from those sites under cyclic loading until they reach a size where conventional fracture mechanics takes over.

Newer comparative work between 6061-T6 and 6082-T6 in corrosive fatigue shows something subtle: 6061-T6 may not always last longer, but it can show less scatter in time to failure, essentially giving you more predictable life in chloride environments. Predictability matters for safety factors and maintenance planning; a tight cluster of failures at 3×10⁵ cycles is easier to design around than a cloud that ranges from 10⁴ to 10⁷ with the same mean.

So, with 6061-T6, you mostly pay attention to three things: surface condition, environment, and stress concentrations. Finish quality, coating, and simple geometry choices can shift fatigue life more than swapping to a slightly stronger aluminum grade.

Most machinists treat 6061-T6 as the “default aluminum” for a reason. Compared with softer tempers, T6 cuts more cleanly and resists the gummy behavior that smears rather than shears at the tool edge. Industrial guides note that moving from O to T6 temper increases hardness and reduces built-up edge, making chip evacuation and surface finish more consistent.

Yet even here the story is not all friendly:

Surface integrity. High-speed milling with aggressive parameters can leave work-hardened layers, residual stresses, and micro-burrs that quietly change fatigue performance, especially near holes and fillets. Those are rarely captured in simple “machinability” ratings.

Coolant and chips. 6061-T6 forms chips that are usually manageable, but tool geometry and coolant strategy still matter. Dry cutting or poor chip evacuation in deep pockets can cook the surface, modify the temper locally, or embed fine debris that turns into corrosion seeds.

Forming. Bending T6 material close to tight radii can push the outer fibers toward strain levels that the alloy will technically survive, but not repeat happily in production; cracking on the tension side, particularly across extrusion grain, is a familiar sight. Many shops quietly specify 6061-T4 for operations that require tight forming, then re-age.

So, yes, 6061-T6 is “easy to machine,” but machining choices still decide whether a part lasts ten thousand cycles or ten million.

Looking across comparison articles for 5052, 6061, and 7075, a pattern appears. 5052 is praised for formability and corrosion resistance, 7075 for strength, and 6061 for being “balanced.” That word is vague, so it helps to phrase the choice differently.

Reach for 6061-T6 when:

You expect welding to be part of the normal process, not an exception. 7xxx alloys can be welded in special conditions, but the cost in process control and post-treatment is non-trivial. 6061 lets average shops produce acceptable welds with standard procedures, as long as you account for HAZ strength reductions in design.

Your environment is outdoors, mildly marine, or just uncertain. Stress-corrosion cracking and aggressive pitting are harder to manage in high-strength 7xxx alloys; 6061-T6 provides a more forgiving starting point, particularly if coated or anodized.

The structure is stiffness-limited, not strength-limited. Both 6061-T6 and 7075-T6 have very similar modulus; if deflection is the main constraint, the gain from the stronger alloy is less than you might think. Geometry changes and joint design can matter more than alloy change.

Cost, availability, and manufacturability are all significant. Pricing moves with market conditions, but 6061’s presence in standard stock and its friendliness to CNC machining, forming (in suitable tempers), and welding tend to keep system-level cost down.

If none of these factors matter and you truly only care about peak strength or fatigue strength in air, then yes, 7075-T6 or other higher-strength alloys start to look better. But that is not as common as it appears in casual conversations.

Engineers who use 6061-T6 for years develop informal rules that rarely show up in datasheets but quietly keep parts alive. They vary by industry, but there is a recurring flavor.

Treat welded regions with their own material allowables, often closer to 6061-T4 levels than pristine T6. The exact numbers depend on filler, procedure, and post-treatment, yet the principle is simple: the alloy designation does not automatically extend across the weld pool and HAZ.

Assume that any part seeing high-cycle loads in a chloride environment is living on the edge if you design it purely from static allowables. Corrosion fatigue data is clear that life drops fast with pits and saline exposure; generous radii, decent coatings, and surface finish control buy you more margin than a small increase in static section modulus.

Align critical tension paths with the rolling or extrusion direction where possible. It is an old habit from plate structures, but still useful: you ride along the grain structure instead of across it, which tends to give better toughness and fatigue performance even if the textbook stress analysis is indifferent.

Treat very thick sections as a slightly different material in practice. Cooling rates and through-thickness microstructure in thick plate can shift properties compared to thin sheet, even if the name on the cert is identical; you see it in elongation trends with thickness and in distortion during machining.

None of these habits are mysterious. They just reflect the idea that “6061-T6” is a broad label for a family of behaviors that change with thickness, processing, joint design, and environment.

If you ignore all nuance, 6061-T6 is “that standard aluminum” for frames, brackets, housings, and profiles. But the reason it has stayed in that role since the 1930s is less romantic: it offers a realistic mix of strength, corrosion behavior, weldability, machinability, and availability that matches how projects really run, with imperfect processes and changing requirements.

Treat it as a stable, well-understood baseline, not as a miracle alloy. Respect the welds, respect surface condition in chloride environments, remember that fatigue is less forgiving than the static numbers suggest, and your 6061-T6 parts will usually fail from some design oversight long before the alloy itself runs out of capability. Which is exactly what most teams want: material that stays boring while everything else changes.